Enthalpy probe for diagnosing thermal plasma

A thermal plasma and probe technology, applied in the direction of reducing unwanted effects, measuring devices, instruments, etc., can solve problems such as unfavorable water cooling, small probe size, and easy burning of the head, so as to improve the cooling effect and improve Accuracy, Effect of Disturbance Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

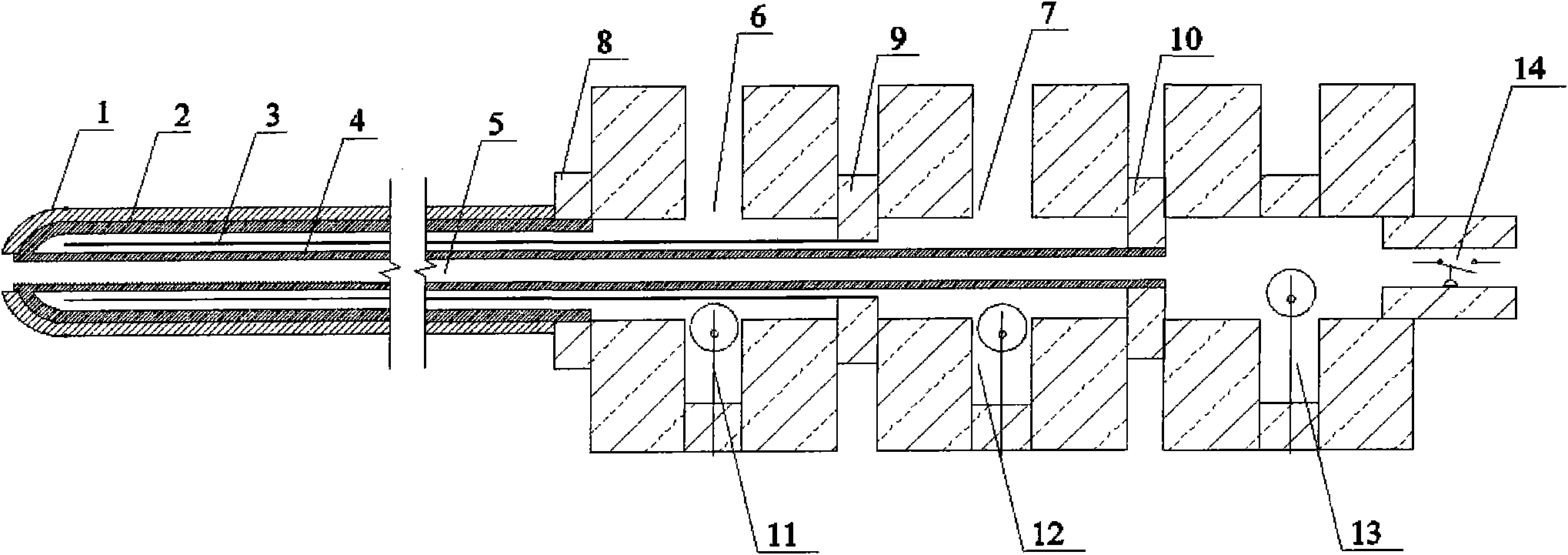

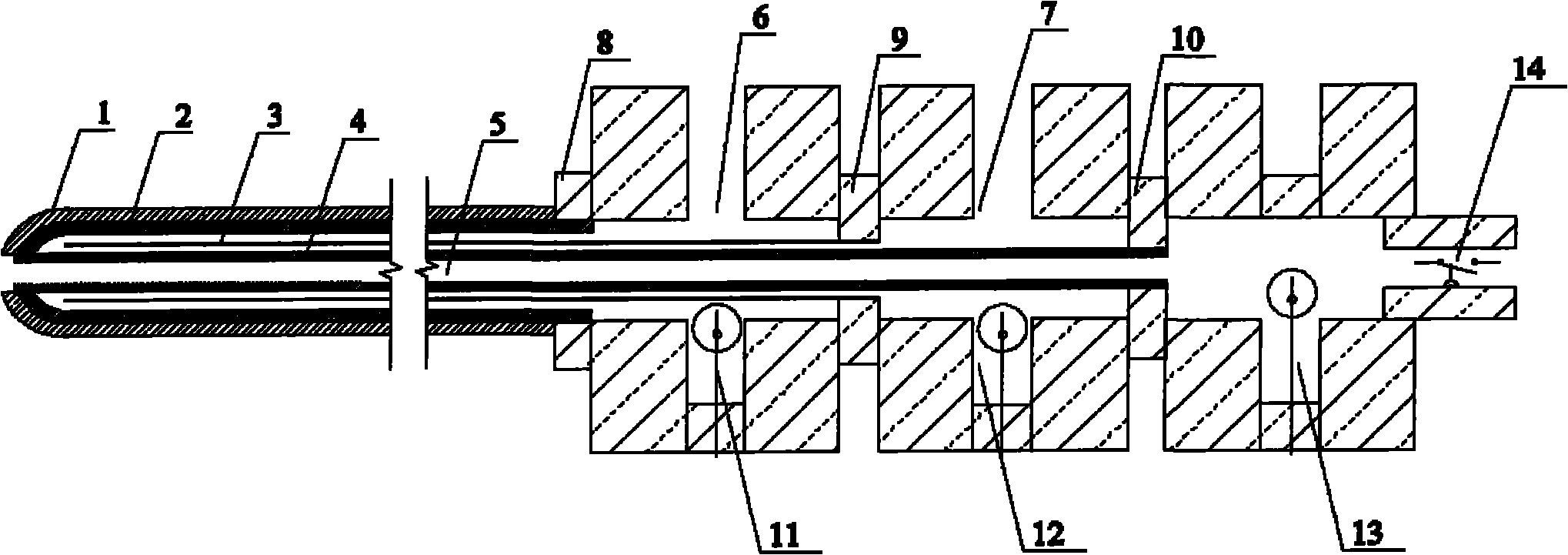

[0019] see figure 1 , an enthalpy probe probe for thermal plasma diagnosis, including a copper outer tube 2 with a wall thickness of 0.5mm, a stainless steel inlet and outlet water separation tube 3 with a wall thickness of 0.2mm, and a copper inner tube with a wall thickness of 0.3mm 4 and the first, second, and third bases 8, 9, and 10, the first, second, and third bases 8, 9, and 10 are all simplified characters, and the head and tail are sealed and welded together, and the front end of the outer tube 2 is hemispherical, and It is sealed and welded with the front end of the inner pipe 4. The inlet and outlet water separation pipe 3 is located between the inner and outer pipes. There is a gap of 4 mm between the inlet and outlet water separation pipe 3 and the outer pipe 2 to form a water inlet channel. There is a gap with the inner pipe 4 and forms a water outlet channel; the ends of the outer pipe 2, the inlet and outlet water separation pipe 3 and the inner pipe 4 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com