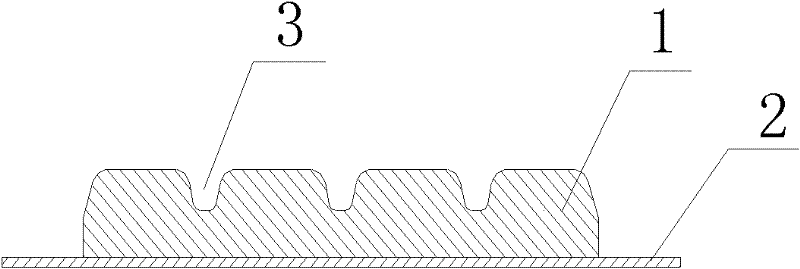

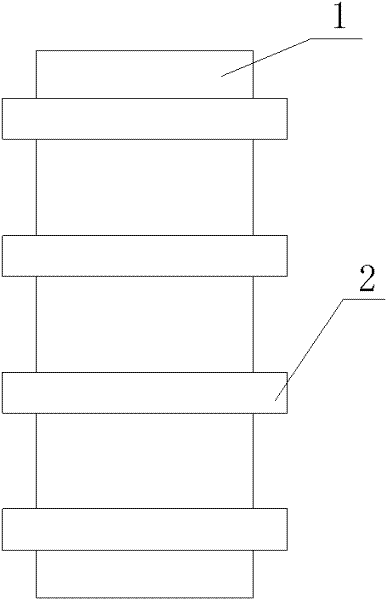

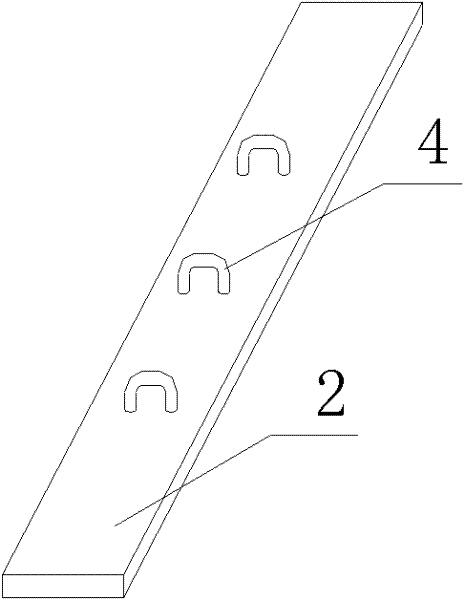

Buffer plate and manufacturing method thereof

A technology of buffer plate and weight ratio, which is applied in the field of buffer plate for dumpers and its manufacturing, to achieve the effect of reasonable structure, strong compression resistance and tear resistance, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The buffer plate is prepared from the following components: 16000g of natural rubber; 1120g of active agent; 352g of peptizer; 320g of vulcanizing agent (S); 192g of accelerator; 320g of polyethylene glycol; Flow dispersant 880g; anti-aging agent 480g; anti-scorch agent 32g. Wherein the accelerator is preferably selected from accelerator NOBS and accelerator DM. In this embodiment, the accelerator consists of 160g of accelerator NOBS and 32g of accelerator DM. The active agent is zinc oxide or a combination of zinc oxide and stearic acid. The active agent in this example consisted of 800 g of zinc oxide and 320 g of stearic acid. The reinforcing filler is composed of high wear-resistant carbon black, semi-reinforcing carbon black and white carbon black in a weight ratio of 4.8-6.8:1-3:0.7-2.5. In this embodiment, the weight ratio of high wear-resistant carbon black, semi-reinforcing carbon black and white carbon black is 5.8:2:1.5. The anti-aging agent can be selecte...

Embodiment 2

[0053] The difference between this embodiment and the embodiments lies in that the proportioning ratio of each component is different. Among them, 9000g of natural rubber; 300g of active agent; 50g of peptizer; 120g of vulcanizing agent (S); 80g of accelerator; 6000g of reinforcing filler; The active agent is zinc oxide. The reinforcing filler is composed of high wear-resistant carbon black, semi-reinforcing carbon black and white carbon black in a weight ratio of 5.2:1.5:2. The accelerator is the accelerator NOBS. Dispersant AT-C is selected as the mobile dispersant.

Embodiment 3

[0055] The difference between this embodiment and the embodiments lies in that the proportioning ratio of each component is different. Among them, 11000g of natural rubber; 800g of active agent; 300g of peptizer; 270g of vulcanizing agent (S); 200g of accelerator; 9000g of reinforcing filler; The active agent is zinc oxide. The reinforcing filler is composed of high wear-resistant carbon black, semi-reinforcing carbon black and white carbon black in a weight ratio of 5.2:1.5:2. The accelerator is accelerator DM. Flow dispersant is selected flow agent AT-42.

[0056] Table 1 below shows the parameters of the above three embodiments.

[0057] Table 1

[0058]

[0059] The buffer plate of the present invention requires the following parameters:

[0060] Hardness (Shore A): 70~85

[0061] Tensile strength: (Mpa)≥5

[0062] Tear strength: kN / m: ≥25

[0063] Compression permanent change (70℃ / 24h, compression 25%): ≤50%

[0064] As can be seen from Table 1, the buffer pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com