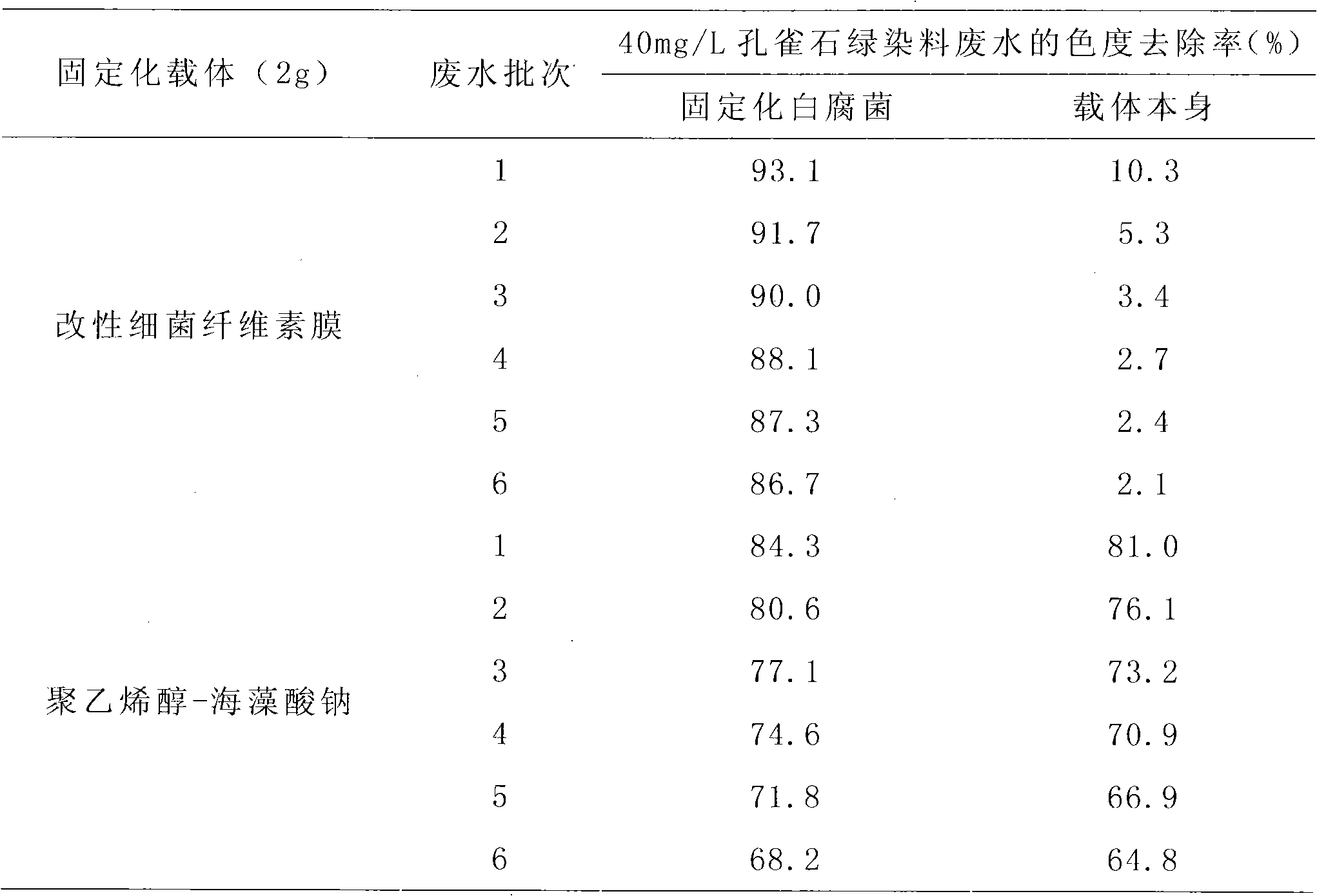

Method for treating malachite green dye waste water

A technology for dye wastewater and malachite green, applied in the field of applied microorganisms and environmental engineering, can solve the problems of complex preparation process, secondary environmental pollution, low immobilization efficiency, etc., and achieves simple operation, small environmental impact and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of white rot fungus spore liquid:

[0025] Pick a small amount of bacteria from the slant of the white-rot fungus with the preserved strain number CGMCC NO: 5.776, and inoculate it on the solid medium by streaking. The percentages are: Potato Dextrose Agar 3.8%; KH 2 PO 4 0.3%; MgSO 4 ·7H 2 O 0.15%, after 5 days of cultivation at 30°C, the spore hyphae of the white rot fungus amplified in large quantities, inject a small amount of sterile water into the plate, scrape off the spore powder with the push rod method, and filter the mycelium through 4 layers of lens-cleaning paper. The obtained milky white spore suspension is the white rot fungus spore liquid, which is stored in a refrigerator at 4°C for subsequent use;

[0026] The white rot fungus used in the above steps was purchased from China General Microorganism Culture Collection and Management Center, and the strain number is CGMCCNO: 5.776.

Embodiment 2

[0028] Preparation of bacterial cellulose membrane:

[0029] The bacterial strain number that is preserved on the slant is CGMCC NO:1.1812 Acetobacter xylinum Gluconacetobacter xylinum is inserted in 50mL seed culture medium, and the percentage that each component consumption accounts for the quality consumption of seed culture medium in the described seed culture medium is respectively: Glucose 2%; peptone 0.5%; yeast extract 0.3%; Na 2 HPO 4 12H 2 O0.2%; KH 2 PO 4 0.1%; MgSO 4 ·7H 2 O 0.025%; citric acid 0.2%; pH5.8; cultivated on an air bath constant temperature shaker at 160rpm for 2 days to obtain an activated Acetobacter xylinum culture solution, take 10mL of this Acetobacter xylinum culture solution and insert it into 125mL fermentation medium , the percentages of the amount of each component in the fermentation medium to the quality of the fermentation medium are as follows: glucose 2%; peptone 0.5%; yeast extract 0.3%; Na 2 HPO 4 12H 2 O0.2%; KH 2 PO 4 0.1%...

Embodiment 3

[0032] Modification of bacterial cellulose membrane:

[0033] Put 40g of bacterial cellulose membrane into 100mL of 1mol / L sodium hydroxide solution, then add 20mL of epichlorohydrin, react in a constant temperature water bath at 60°C for 30min, take out the membrane and wash it with acetone to remove the residues on the membrane. Small molecular organic matter; after washing with water, add 5.5mL of ethylenediamine and 49.5mL of distilled water, shake fully, heat in a constant temperature water bath at 80°C for 30min, then take out the membrane and wash it with distilled water until it is neutral, and then use 1% weight After washing 3 times with hydrochloric acid with a certain percentage content, wash with distilled water until neutral, then rinse with acetone, and then vacuum-dry to constant weight. At this time, the flexibility of the film becomes stronger, and the surface is light yellow, smooth and shiny. It is a modified bacterial cellulose membrane;

[0034] Immobili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com