Full-automatic polishing tool for environmental ultrahard coating corrugator roll

A corrugated roll, fully automatic technology, applied in the field of automatic environmental protection corrugated roll polishing machine tools, can solve problems such as affecting the bonding strength of the coating and the corrugated roll, the inability of the profiling electrode, and the matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

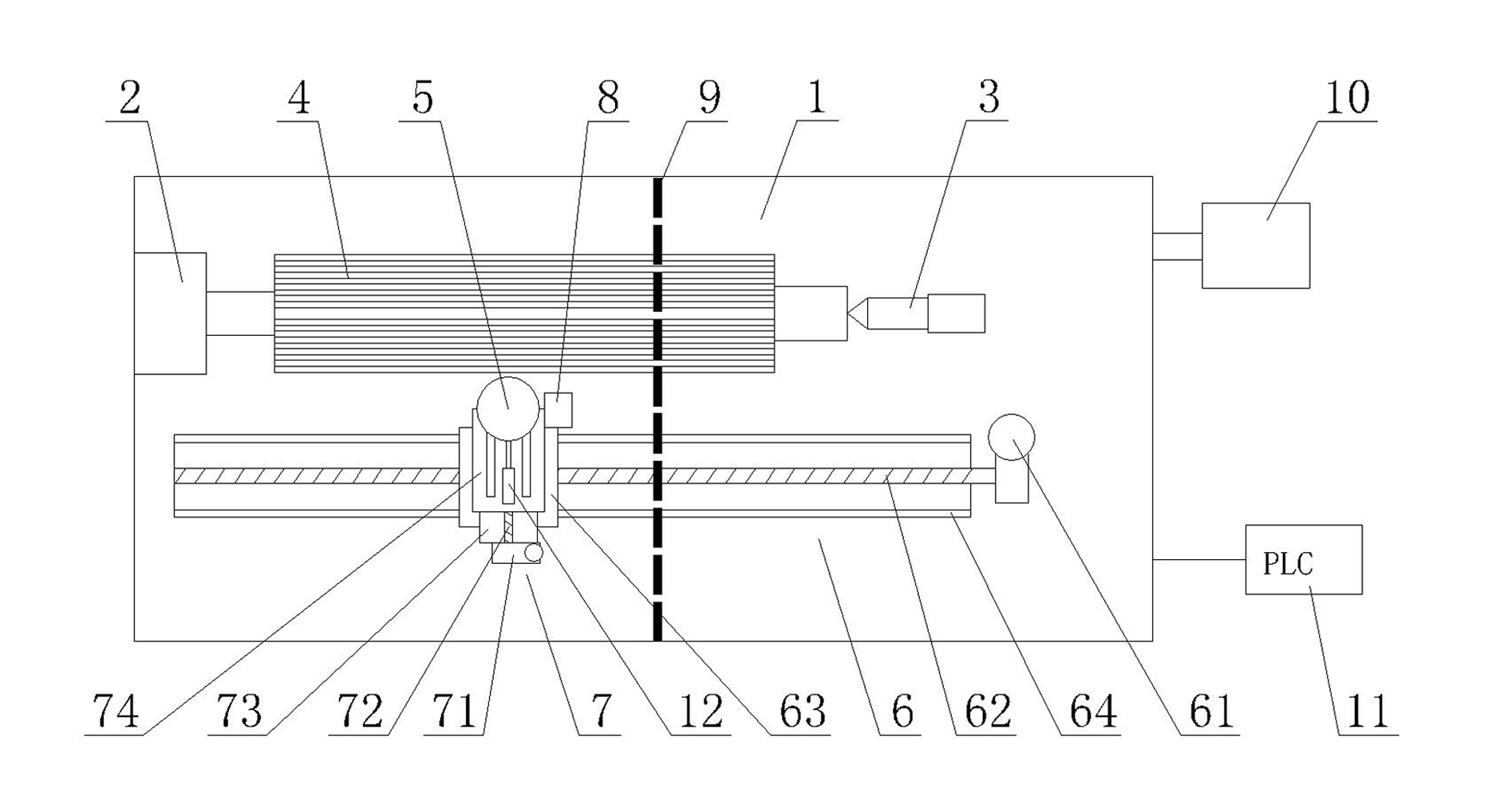

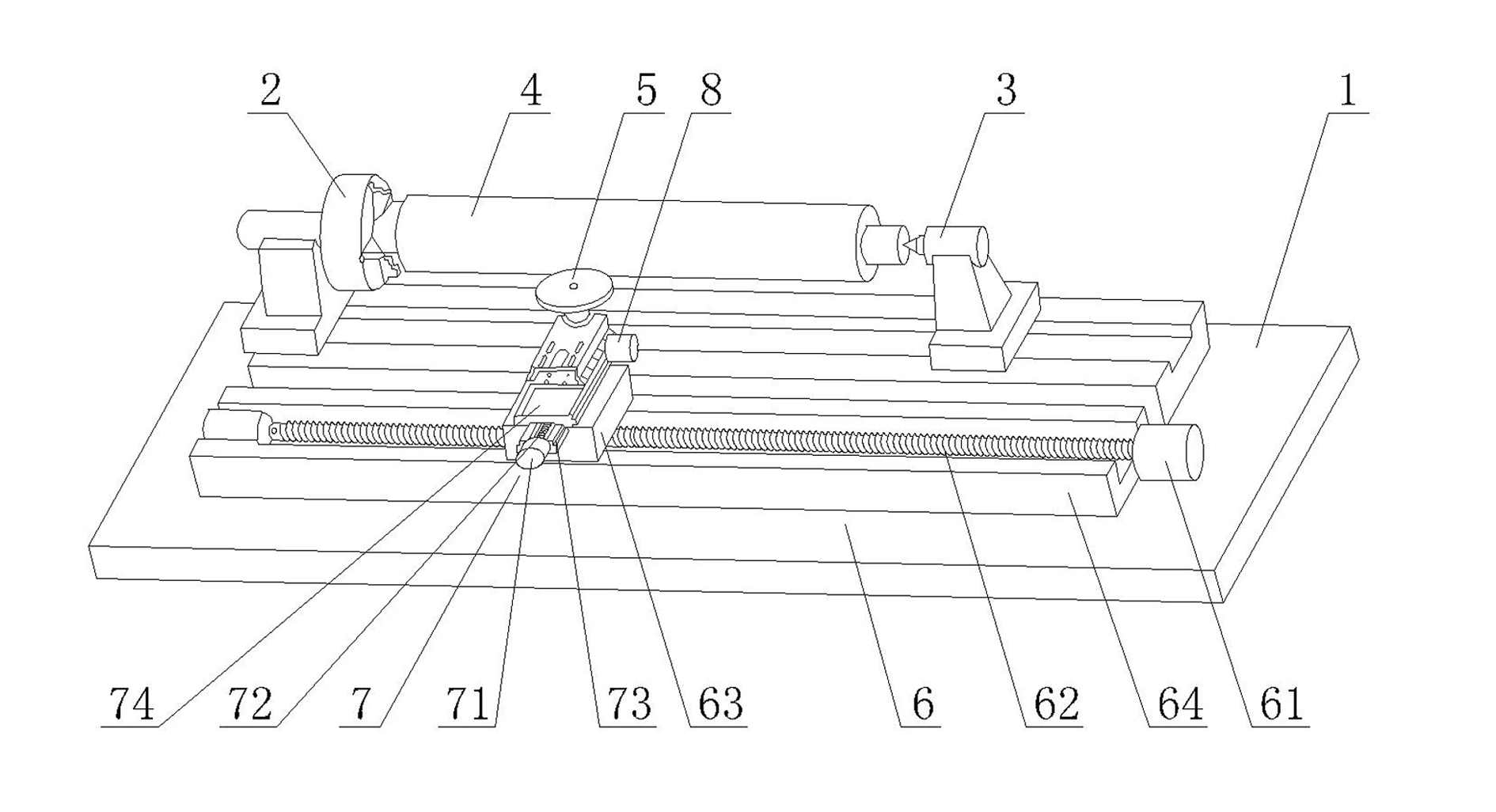

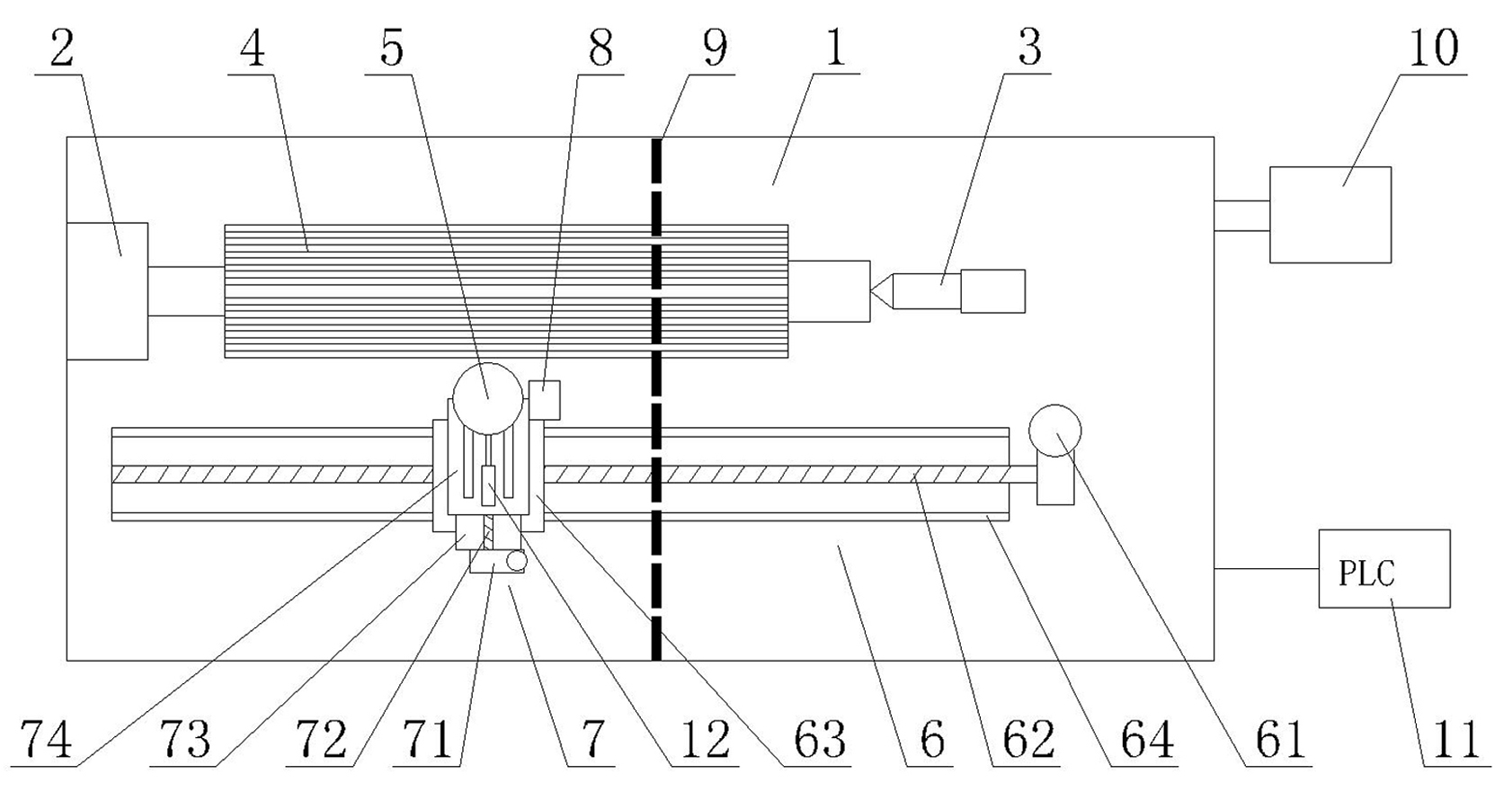

[0016] Such as Figure 1-Figure 2 As shown, the fully automatic environment-friendly corrugated roller polishing machine tool of the present invention includes a control platform 1, a ventilation and dust removal device and a control device 11, wherein the control platform 1 is provided with graduations for clamping and adjusting the angle of the corrugated roller 4 to be processed The chuck 2 and the tailstock top 3, the flexible polishing wheel 5 for polishing the corrugated roll 4 to be processed, the horizontal driving device 6 for driving the flexible polishing wheel 5 to move in the horizontal direction, and the horizontal driving device 6 for driving the flexible polishing wheel 5 to move along the horizontal direction A vertical driving device 7 moving in the vertical direction and a power driving device 8 for driving the flexible polishing wheel 5 to rotate. Among them, the corrugating roller 4 generally has a diameter between Ф200-600 mm and a length of about 1000-60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com