Tissue temperature indicating element for ultrasound therapy

A technology of indicating element and tissue, applied in the field of tissue temperature indicating element, can solve the problems of blocking eyes, unable to achieve fast enough temperature control, impractical visual inspection of thermally active film, etc., to achieve the effect of avoiding the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

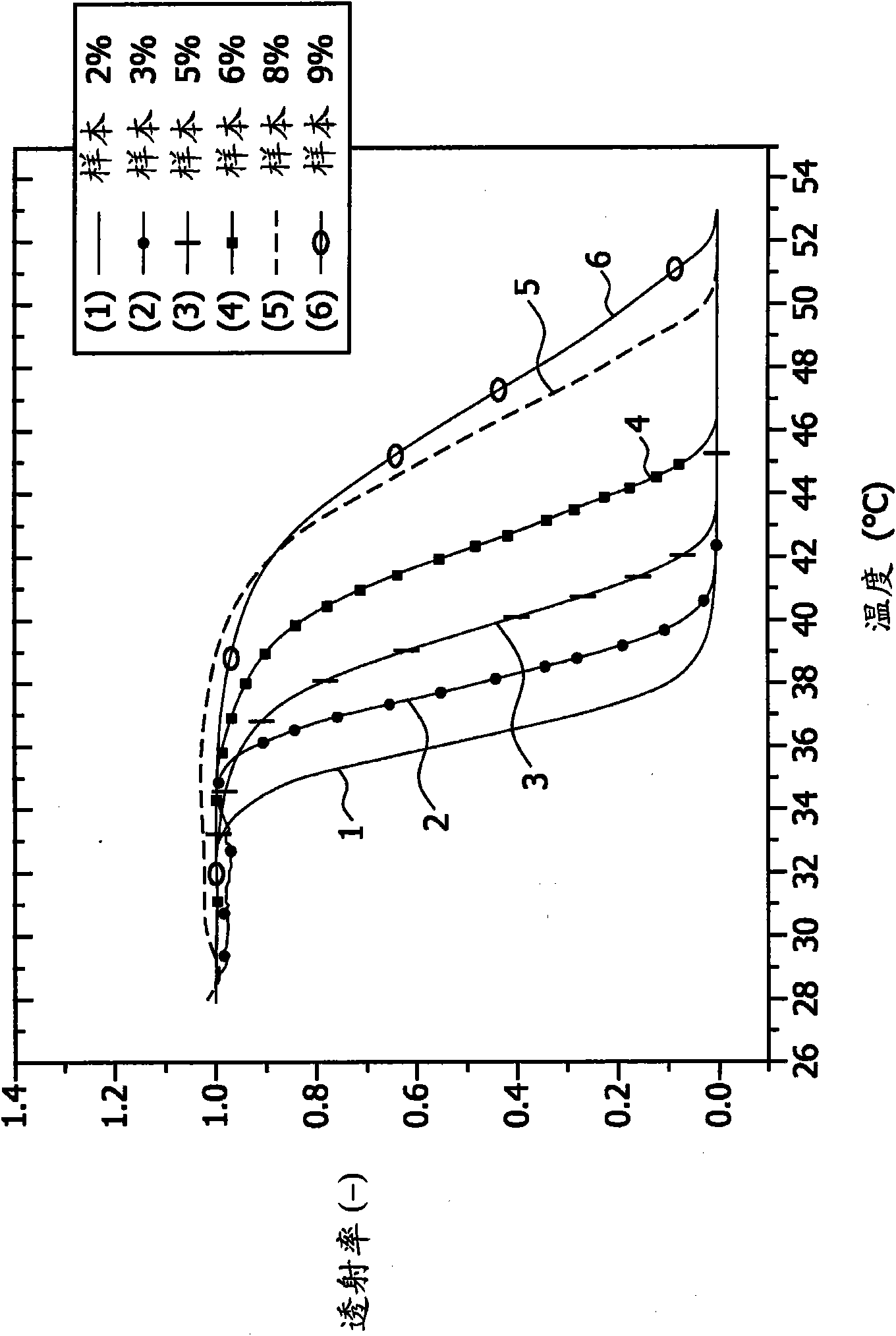

[0109] 65 parts by weight of polymer (which is commercially available from Merck under the name LCP93; below is the chemical formula, degree of polymerization m+n=40; transition from smectic to isotropic at 97°C according to Merck)

[0110] With 35 parts by weight of ethoxylated bisphenol-A diacrylate (trade name is Sartomer 349, which can be purchased from Sartomer, USA). The two materials have a similar refractive index of about 1.55, avoiding light scattering when the liquid crystal polymer LCP093 is heated above its liquid crystal transition temperature. For curing, the samples were mixed with 2 parts by weight of photoinitiator (trade name Irgacure 651, which is available from Ciba Specialty Chemicals in Switzerland). The mixture forms a paste that can be printed onto a substrate with the aid of a PDMS mold. Curing is achieved by using a UV light source PL10 lamp (Philips - intensity 0.6mW.cm- 2 365nm light) irradiation. The sample changed in appearance from highly...

example 2

[0112] Figure 6 The liquid crystal molecules are mixed with ethoxylated bisphenol A diacrylate. UV light was used to photopolymerize the mixture in the presence of a photoinitiator (2 weight percent Irgacure 651, commercially available from Ciba Specialty Chemicals, Sweden). The transition temperature from scattering to clear was subsequently observed between 60°C and 61°C using a charge-coupled device (CCD) camera.

example 3

[0114] A mixture of biocompatible polymer (poly(lactic-co-glycolic acid, PLGA), liquid crystal (n-pentylcyanobiphenyl) and dichloroethylene (DCE) as a solvent is injected into the water through an inkjet nozzle (The ratio of PLGA: LC: DCE is 0.05: 0.20: 99.75, and 0.3 weight percent of polyvinyl alcohol is added as a stabilizer to H 2 O to prevent coalescence of the emulsion droplets), and LC-filled polymer capsules were obtained. After water removal, the capsules were dispersed in the monomer system (ethoxylated bisphenol-A + 2 weight percent Irgacure 651 from Ciba Specialty Chemicals), and the resulting mixture was cured by photopolymerization of the monomer system . The transition temperature from scattering to clear was then observed at 35°C and occurred within a temperature interval not exceeding 1°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com