Method for preparing monoclinic gallium oxide single-crystal film on magnesium oxide substrate

A technology of single crystal thin film and monoclinic crystal type, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problem of large substrate lattice mismatch, unsuitable for industrial production, and unsatisfactory crystallization quality, etc. low epitaxial growth temperature, precise control of process conditions, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

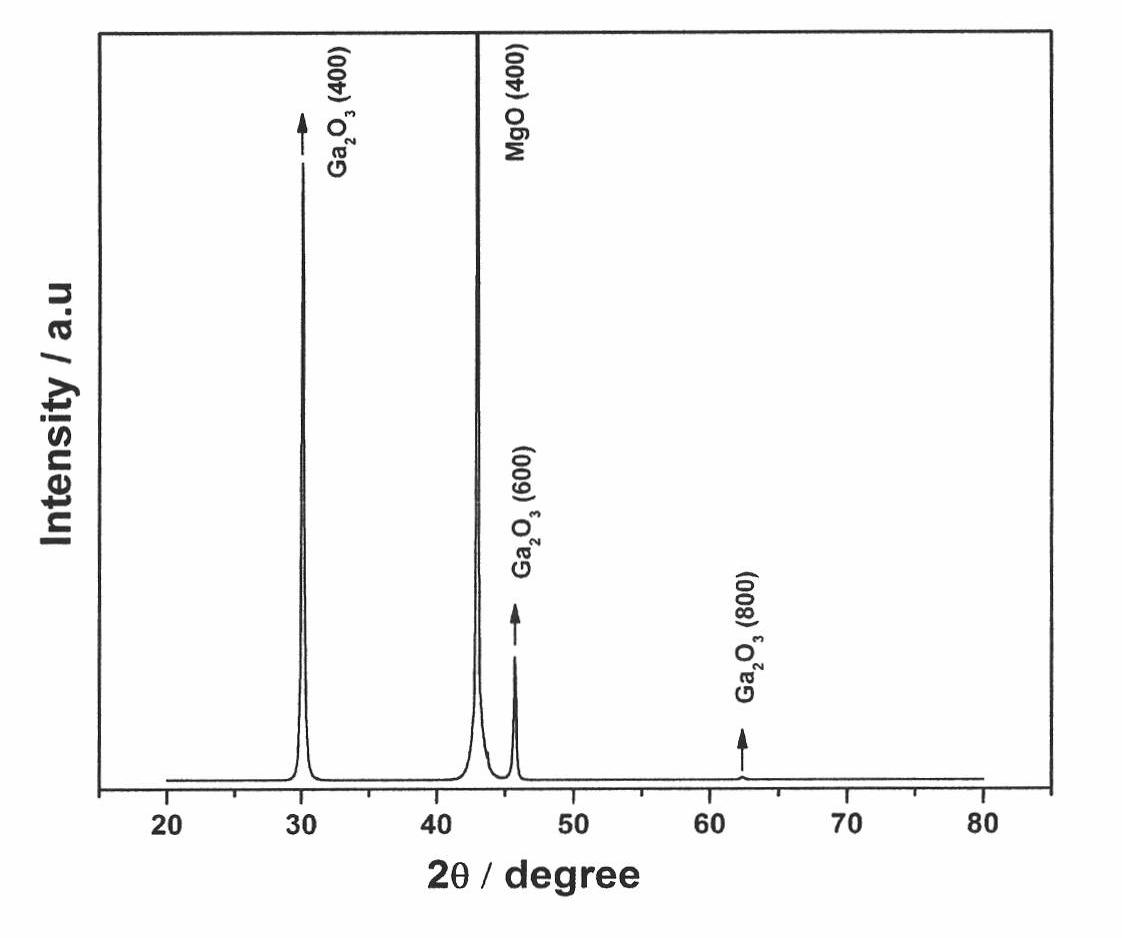

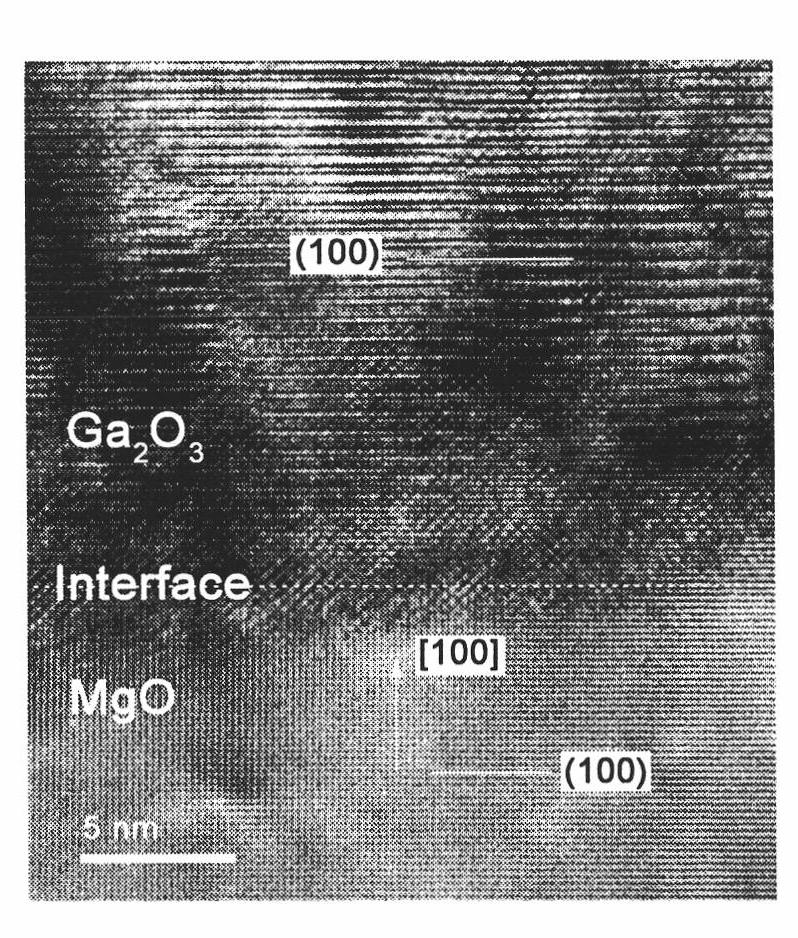

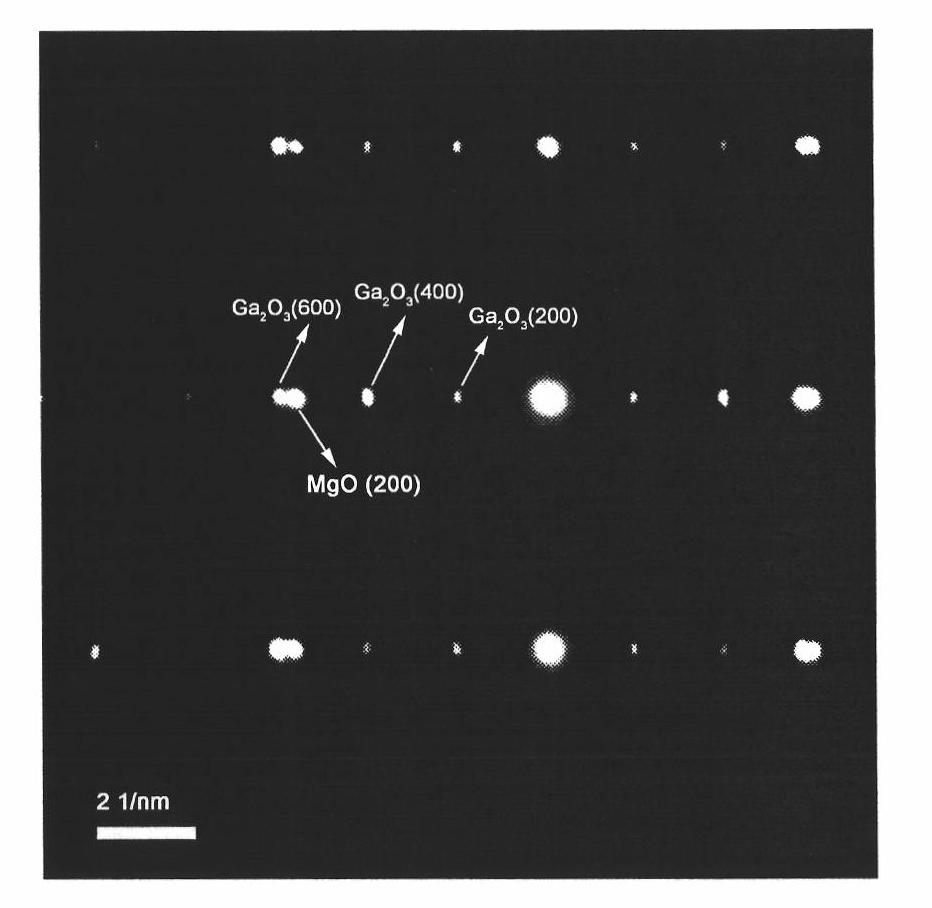

[0054] Example 1: Preparation of Monoclinic Gallium Oxide Single Crystal Thin Film Material by MOCVD Technology

[0055] With the polished MgO(100) surface as the substrate material, trimethylgallium [Ga(CH 3 ) 3 ] As an organometallic source, a gallium oxide single crystal thin film was prepared at 650°C, and the steps were as follows:

[0056] (1) First pump the reaction chamber of the MOCVD equipment to a high vacuum state of 5×10 -4 Pa, heat the substrate to 650°C;

[0057] (2) Open the valve of the nitrogen cylinder and feed nitrogen into the reaction chamber (background N 2 500sccm) for 30 minutes, the reaction chamber pressure was stabilized at 120Torr;

[0058] (3) Open the valve of the oxygen cylinder, adjust the flow rate of oxygen to 50 sccm, and keep it for 10 minutes;

[0059] (4) Open the valve of the gallium source bottle, adjust the flow rate of the carrier gas (nitrogen) to 2 sccm, and keep it for 10 minutes;

[0060] (5) Pass oxygen and organometallic g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com