Method for preparing Ni-P-UFD composite coating by chemical plating or electroplating process

An electroplating process and composite coating technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve problems such as uneven distribution, changes in chemical and physical properties of the plating solution, and unstable process, and achieve increased Improvement of wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

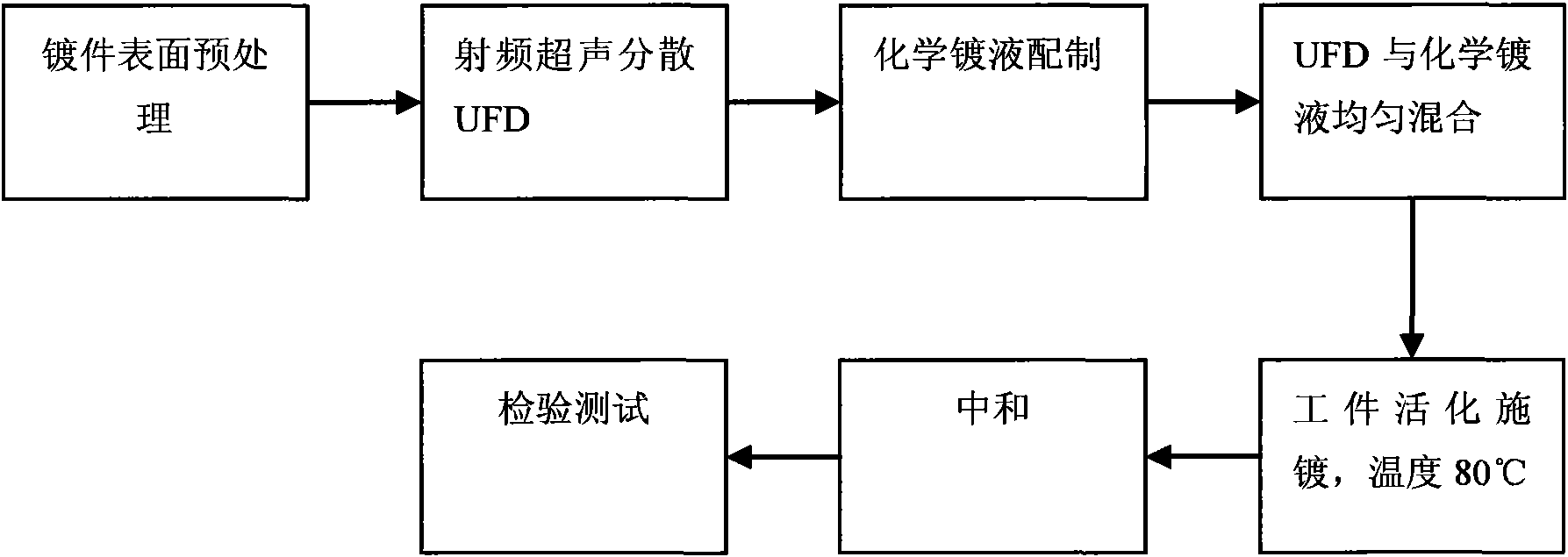

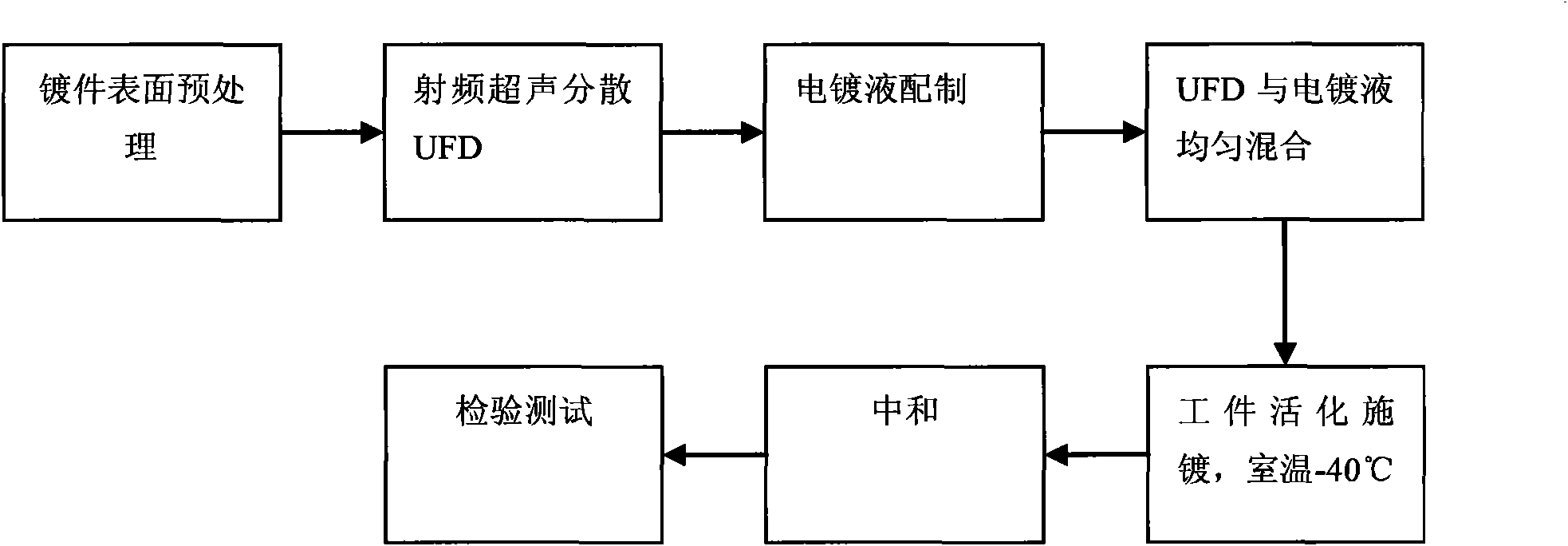

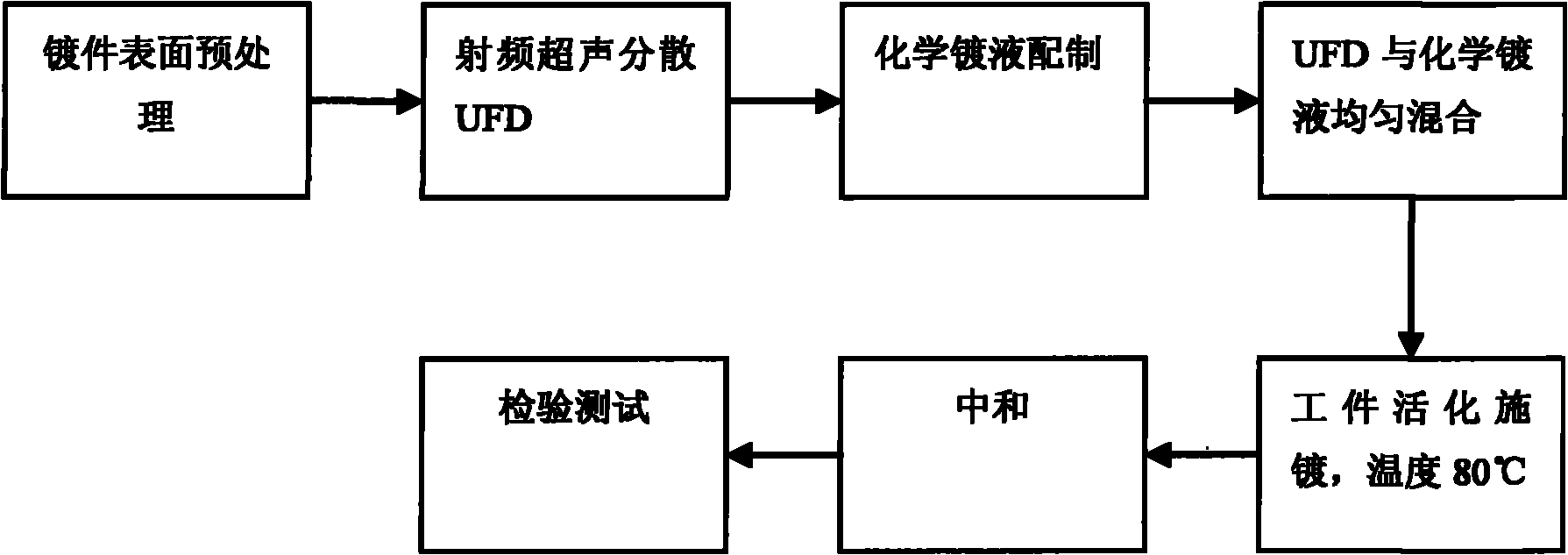

[0026] The present invention will be further described below in conjunction with the accompanying drawings. like figure 1 Shown, a kind of method for preparing Ni-P-UFD composite coating with electroless plating process comprises the following steps:

[0027] A. First, use No. 1000 SiC sandpaper to polish the surface of the plated workpiece, then ultrasonically clean it with 5% washing powder aqueous solution, then soak it in 0.4mol NaOH aqueous solution at 95°C for 10 minutes, and dry it for later use;

[0028] B. Before preparing the coating, put the workpiece to be plated in 5% H 2 SO 4 Soak in the aqueous solution for 1min for surface activation treatment, then connect the plated workpiece to the negative pole of the power supply, and connect the metal Ni plate to the positive pole of the power supply;

[0029] C. Take 1g of UFD powder, add 20ml of deionized water and 0.5g of polyvinylpyrrolidone, and use a high-power radio frequency ultrasonic disperser to perform rad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com