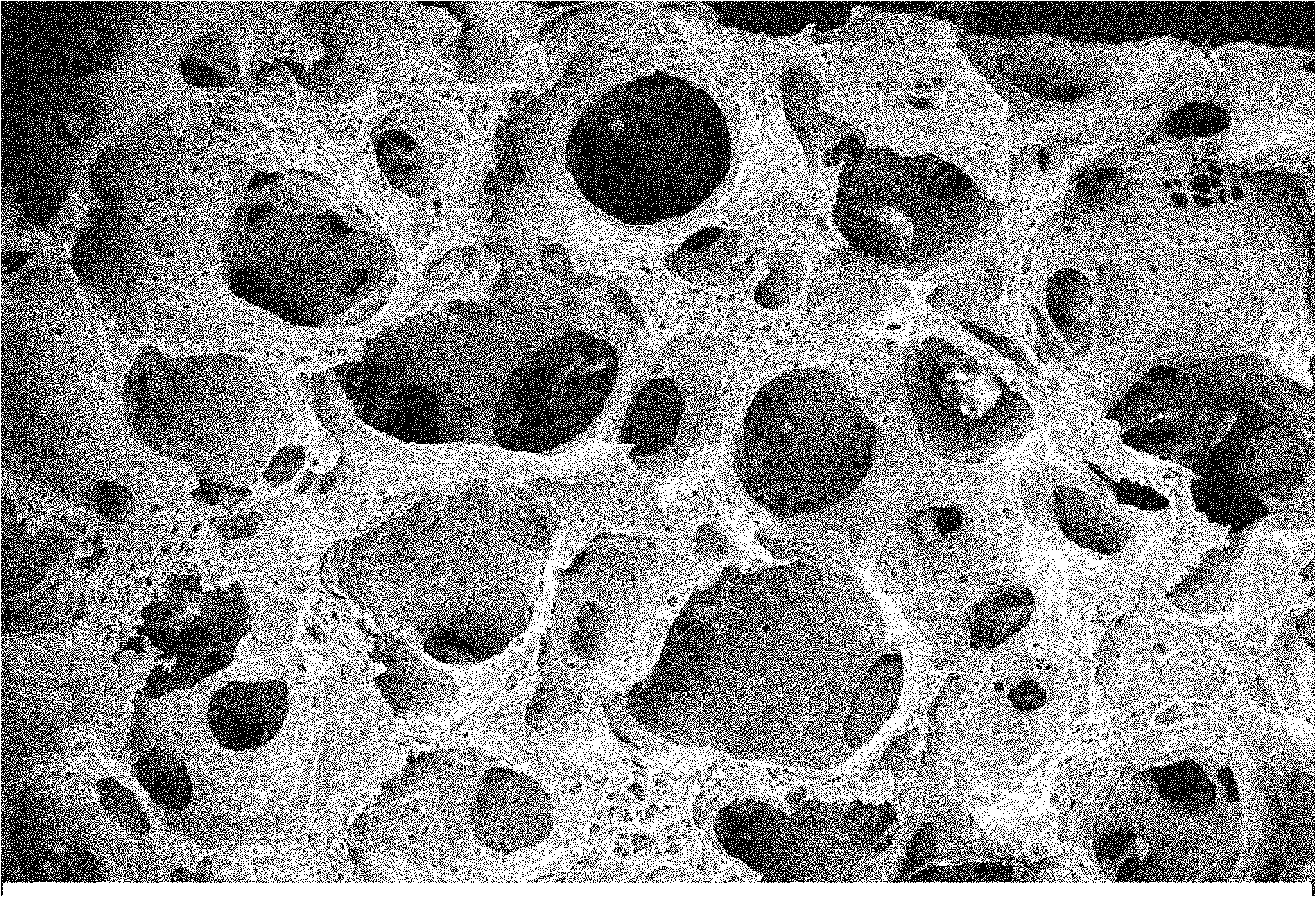

Medicinal microporous sponge and preparation method thereof

A microporous sponge and sponge technology, applied in medical science, absorbent pads, bandages, etc., can solve the problems of uneven pores, residues, foaming agents or porogens in medical sponges, etc., achieve soft texture and reduce raw materials Effects of using and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

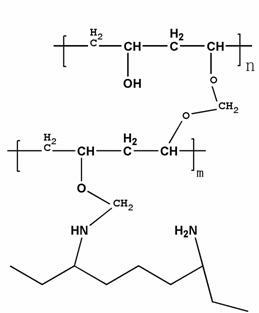

[0076] Described medical microporous sponge, its preparation method mainly comprises the following steps:

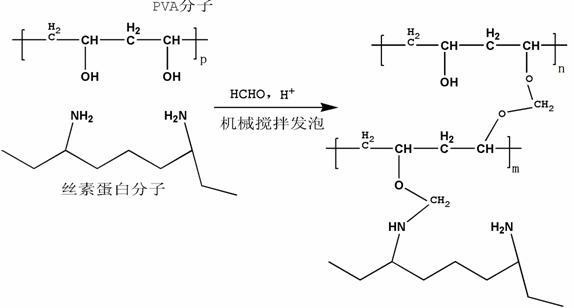

[0077] 1) PVA solution and silk fibroin solution are mixed, stirred into a uniform mixed solution, and heated slowly;

[0078] 2) Acetal reaction: Stir for a certain period of time, add a certain volume of formaldehyde aqueous solution to the mixed solution in step 1, continue stirring for a certain period of time, and then add a certain volume of acid solution, PVA and silk fibroin under the action of acidic conditions and formaldehyde, Acetal reaction occurs, and cross-linking occurs between molecules;

[0079] 3) Adjust the stirring speed to stop:

[0080] 4) curing molding;

[0081] 5) Release and wash;

[0082] 6) Freeze drying and processing.

[0083] Wherein, the first step may further include stirring and adding alkylphenol polyoxyethylene ether OP to the mixed solution; the mechanically stirred blades used in the preparation process are at least 2-3 layers, ...

example 1

[0099] The specific preparation method of biomedical microporous foam prepared by mechanical foaming method comprises the following steps:

[0100] (1) Mix 20g of PVA with 200g of deionized water, stir mechanically to gradually dissolve the PVA to prepare a PVA solution, then add 3ml of 1% silk fibroin solution, stir evenly, slowly heat to 60°C, and mechanically Adjust the stirring speed to 800 rpm, and after stirring for 6 minutes, add 3 grams of OP to every 100ml of the mixture;

[0101] (2) After stirring for 5 minutes, add 37% formaldehyde solution, the amount added is 11ml formaldehyde solution per 100ml solution, continue stirring for 5 minutes, and then add sulfuric acid solution with a concentration of 50%, the amount of acid added is 100ml Add 12ml acid solution to the solution;

[0102] (3) Start to reduce the stirring speed after stirring for 8 minutes, and reduce the stirring speed to 200r / min within 5 minutes, and stop stirring after 1 minute;

[0103] (4) Pour in...

example 2

[0107] The specific preparation method of biomedical microporous foam prepared by mechanical foaming method comprises the following steps:

[0108] (1) Mix 25g of PVA with 220g of deionized water, stir mechanically to gradually dissolve the PVA, and prepare a PVA solution, then add 2ml of 4% silk fibroin solution, stir evenly, and slowly heat to 50°C, then put Adjust the mechanical stirring speed to 1000 rpm, and after stirring for 5 minutes, add 1 g of OP to every 100 ml of the mixture;

[0109] (2) After stirring for 4 minutes, add 37% formaldehyde solution, the addition amount is 10ml formaldehyde solution per 100ml solution, continue stirring for 4 minutes, then add 37% hydrochloric acid solution, the acid addition amount is 100ml solution Add 50ml acid solution;

[0110] (3) After stirring for 6 minutes, start to reduce the stirring speed, within 5 minutes, the stirring speed will drop to 200r / min, and stop stirring after 1 minute;

[0111] (4) Pour into the mold, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com