Packaging method capable of carrying out super miniaturization on fiber-coupled acousto-optic device collimator

An optical fiber coupling, acousto-optic device technology, applied in the coupling of optical waveguides, optics, instruments, etc., can solve the problems of inability to meet the thermal stability requirements of the device, unfavorable device miniaturization, high angle sensitivity, and save the use of raw materials. , volume reduction, the effect of meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

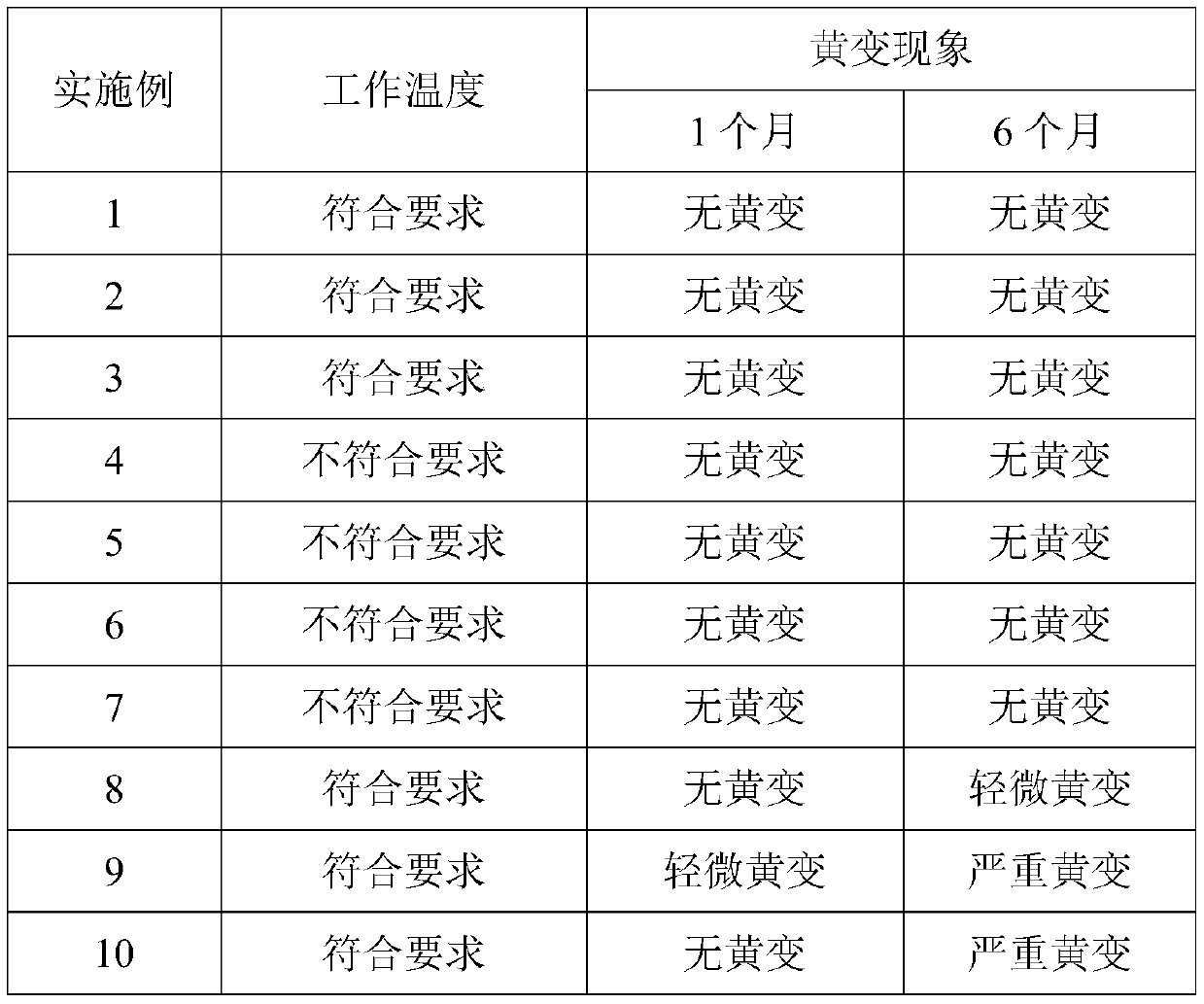

Examples

Embodiment 1

[0090] Embodiment 1 provides a method for packaging an ultra-miniaturized fiber-coupled acousto-optic device collimator, comprising the following steps:

[0091] 1) A hole is respectively opened on the side wall of the casing containing the acousto-optic crystal, wherein the angle between the hole and the outer side wall is 24 milliradians, the thickness of the side wall is 4mm, and the aperture is 3mm;

[0092] 2) Pass two glass tubes with an outer diameter of 2.8 mm through the holes described in step 1) respectively, and apply single-component polyurethane glue on the outer walls of the glass tubes in contact with the holes to fix the glass tubes;

[0093] 3) Place two identical optical fiber collimators designed to be clamped by the six-dimensional adjustment frame into the glass tubes on both sides, adjust the position and direction of the collimators, and after all are fixed, loosen the six-dimensional adjustment frame. The collimator clamp, remove the adjustment frame; ...

Embodiment 2

[0101] Embodiment 2 provides a method for packaging an ultra-miniaturized fiber-coupled acousto-optic device collimator, comprising the following steps:

[0102] 1) A hole is respectively opened on the side wall of the casing containing the acousto-optic crystal, wherein the angle between the hole and the outer side wall is 24 milliradians, the thickness of the side wall is 3mm, and the aperture is 2.5mm;

[0103] 2) Pass two glass tubes with an outer diameter of 1.8 mm through the holes described in step 1) respectively, and apply single-component polyurethane glue on the outer walls of the glass tubes in contact with the holes to fix the glass tubes;

[0104] 3) Place two identical optical fiber collimators designed to be clamped by the six-dimensional adjustment frame into the glass tubes on both sides, adjust the position and direction of the collimators, and after all are fixed, loosen the six-dimensional adjustment frame. The collimator clamp, remove the adjustment frame...

Embodiment 3

[0112] Embodiment 3 provides a method for packaging an ultra-miniaturized fiber-coupled acousto-optic device collimator, comprising the following steps:

[0113] 1) A hole is respectively opened on the side wall of the casing containing the acousto-optic crystal, wherein the angle between the hole and the outer side wall is 24 milliradians, the thickness of the side wall is 5mm, and the aperture is 3.5mm;

[0114] 2) Pass two glass tubes with an outer diameter of 3.5 mm through the holes described in step 1) respectively, and apply single-component polyurethane glue on the outer walls of the glass tubes in contact with the holes to fix the glass tubes;

[0115] 3) Place two identical optical fiber collimators designed to be clamped by the six-dimensional adjustment frame into the glass tubes on both sides, adjust the position and direction of the collimators, and after all are fixed, loosen the six-dimensional adjustment frame. The collimator clamp, remove the adjustment frame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com