Method for preparing aluminum nitride single crystal whiskers

A technology of aluminum nitride and single crystal, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., to reduce the use of raw materials, improve safety and reliability, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

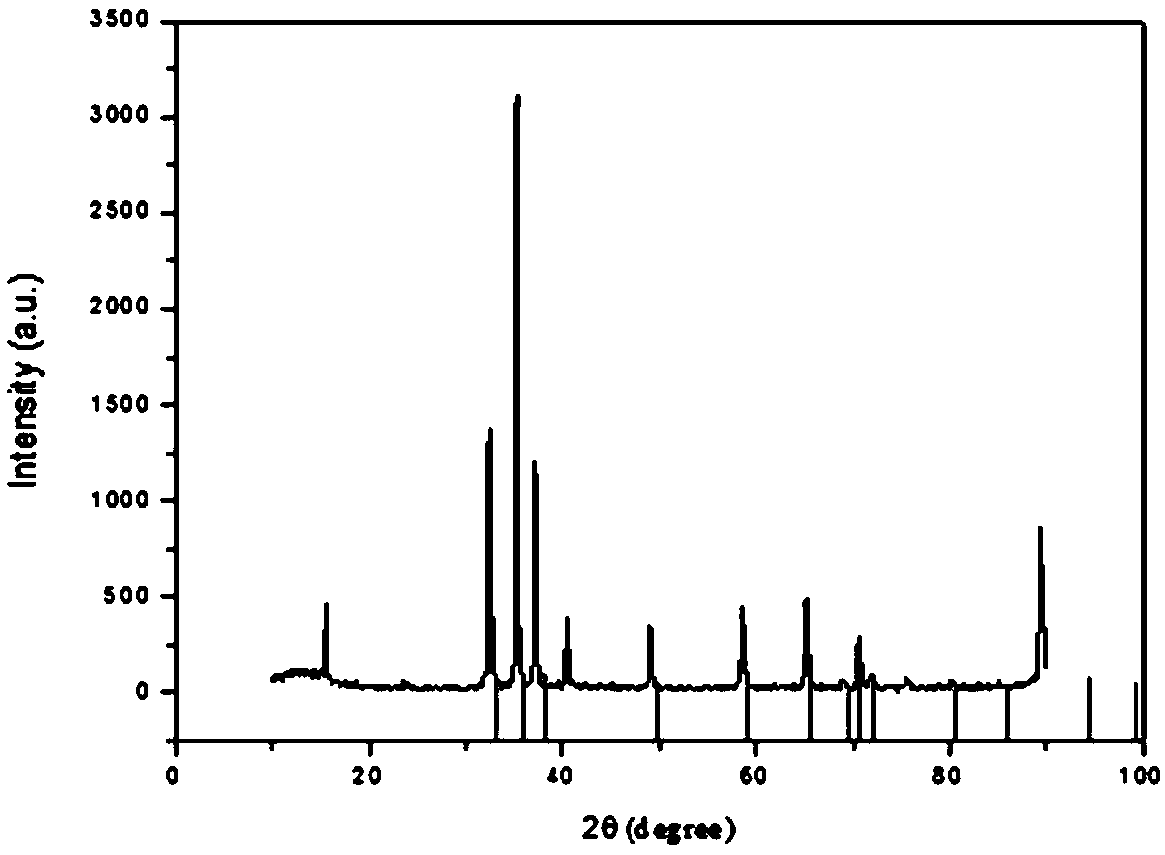

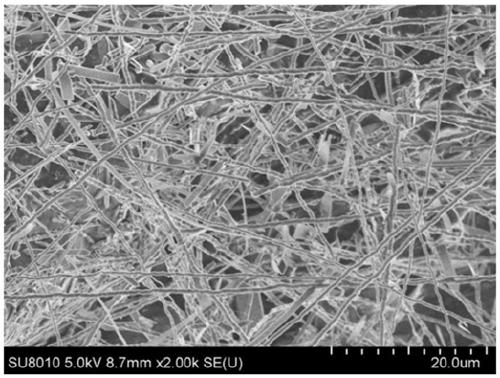

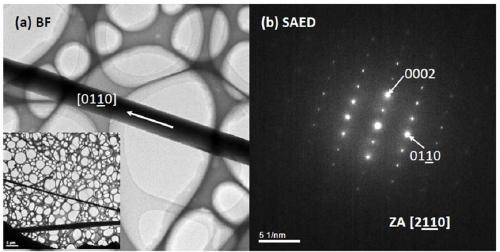

Image

Examples

Embodiment 1

[0016] 1) Weigh 1g of aluminum particles with a purity of 99.999% and put them into a corundum boat for later use; use acetone and isopropanol to ultrasonically clean the surface of the sapphire for 10 minutes, and dry it for later use;

[0017] 2) One end of the corundum tube in the reaction chamber of the hydride vapor phase epitaxy equipment is connected to the air inlet, and the corundum boat filled with aluminum particles in step 1) is pushed into the corundum tube from the other end until it reaches the source area, and the substrate is placed at a distance from the corundum tube. Port 5 ~ 10cm;

[0018] 3) During the aluminum nitride growth process, the reaction chamber was first evacuated to 8Pa, and then 0.1L / min nitrogen gas was introduced, the temperature of the source area was raised to 1400°C, and the temperature of the growth area was raised to 1550°C. After the temperature reaches the set value, adjust the flow rate of the nitrogen gas path to 1.1L / min, the flow...

Embodiment 2

[0021] 1) Weigh 1g of aluminum particles with a purity of 99.999% and put them into a corundum boat for later use; use acetone and isopropanol to ultrasonically clean the surface of the sapphire for 10 minutes, and dry it for later use;

[0022] 2) One end of the corundum tube in the reaction chamber of the hydride vapor phase epitaxy equipment is connected to the air inlet, and the corundum boat filled with aluminum particles in step 1) is pushed into the corundum tube from the other end until it reaches the source area, and the substrate is placed at a distance from the corundum tube. Port 5 ~ 10cm;

[0023] 3) During the growth process of aluminum nitride nanowires, the reaction chamber was first evacuated to 29Pa, and then 0.1L / min nitrogen gas was introduced, the temperature of the source area was raised to 1400°C, and the temperature of the growth area was raised to 1550°C. After the temperature reaches the set value, adjust the flow rate of the nitrogen gas path to 1.1L...

Embodiment 3

[0027] 1) Weigh 1g of aluminum particles with a purity of 99.999% and put them into a corundum boat for later use; use acetone and isopropanol to ultrasonically clean the surface of the sapphire for 10 minutes, and dry them for later use;

[0028] 2) One end of the corundum tube in the reaction chamber of the hydride vapor phase epitaxy equipment is connected to the argon gas inlet, and the corundum boat filled with aluminum particles in step 1) is pushed into the corundum tube from the other end to the position of the source area, and the substrate is placed at a distance from Corundum tube port 5 ~ 10cm;

[0029] 3) During the growth process of aluminum nitride nanowires, the reaction chamber was first evacuated to 23Pa, and then 0.1L / min nitrogen gas was introduced, the temperature of the source area was raised to 1400°C, and the temperature of the growth area was raised to 1550°C. After the temperature reaches the set value, adjust the flow rate of nitrogen gas path to 4L / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com