Acrylate polymer high oil absorption resin and preparation method and application thereof

A super oil-absorbing resin, acrylate technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve the phenomenon of difficult coagulation, low oil absorption rate, synthetic resin purity, performance, application range Production technology Difficult to control and other problems, to achieve the effect of wide application range and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

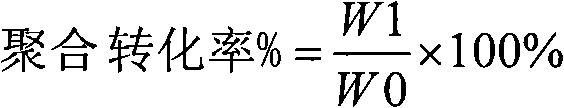

Method used

Image

Examples

Embodiment 1

[0055] 1) formula (in parts by weight):

[0056]

[0057] 2) Preparation:

[0058] Add the ingredients according to the above formula, add them into the irradiation device with stirring, reflux condensation, temperature control, nitrogen gas flow and the upper cover can be opened, disperse with 40KHz ultrasonic for 20 minutes, pass high-purity nitrogen gas for 20 minutes, then seal it with nitrogen gas, put it away enter 60 The position where the absorbed dose rate of the Co radiation source is 75.5014Gy / min is taken out when the absorbed radiation dose is 7.210kGy, and a transparent gel-like acrylate polymer is obtained, which is sealed at low temperature and protected from light for future use.

[0059] Put the transparent gel-like acrylate polymer into a device with a designed shape, and dry it to constant weight at about 100°C (while recovering the solvent), to obtain the acrylate polymer super oil-absorbing resin of the present invention. After testing, the saturated...

Embodiment 2

[0061] 1) formula (in parts by weight):

[0062]

[0063] 2) Preparation:

[0064] Add the ingredients according to the above formula, add them to the irradiation device with stirring, reflux condensation, temperature control, nitrogen gas flow and the ability to uncover the top cover, stir at a speed of 80 rpm for 20 minutes, and seal after 25 minutes with high-purity nitrogen; put into a 60 The position where the absorbed dose rate of the Co radiation source is 100.1975Gy / min is taken out when the absorbed radiation dose is 2.988kGy, and a transparent gel-like acrylate polymer is obtained, which is sealed at low temperature and protected from light for future use.

[0065] Put the above-mentioned transparent gel-like acrylate polymer into a device with a designed shape, and vacuum-dry to constant weight (while recovering the solvent) to obtain the acrylate polymer super oil-absorbing resin of the present invention. After testing: the saturated oil absorption (g / g) of th...

Embodiment 3

[0067] 1) formula (in parts by weight):

[0068]

[0069] 2) Preparation:

[0070] Add the ingredients according to the above formula ratio into the reaction device with stirring, reflux condensation, temperature control, nitrogen gas flow and the ability to uncover the upper cover, stir at a speed of 80 rpm for 15 minutes, and pass high-purity nitrogen gas for 20 minutes. 60 The position where the absorbed dose rate of the Co radiation source is 20.2306Gy / min is taken out when the controlled radiation absorbed dose is 14.570kGy. A transparent gel-like polyacrylate is obtained, and the product is sealed at low temperature and protected from light for future use.

[0071] The preparation of the oil-absorbing resin is to put the product into a device with a designed shape, and dry it to a constant weight at about 80° C. (while recovering the solvent), so as to obtain the acrylate polymer super oil-absorbing resin of the present invention.

[0072] The saturated oil absorpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com