Hydrosoluble reduced enzyme Q10 composition and preparation method thereof

A technology of reduction and composition, which is applied in the field of medicine, can solve the problems of unreported water-soluble reduced coenzyme Q10, etc., and achieve the effect of no suspension or precipitation, high stability and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prepared by first dissolving reduced coenzyme Q10 in an organic solvent and then mixing it with an emulsifier:

[0035] Take 10g of reduced coenzyme Q10 and 20g of polyoxyethylene-40-stearate, dissolve in 20ml of ethyl acetate, stir to form a clear and transparent solution as a spare solution; take 1000ml of 50°C hot water, add 69g of pure gum and 1g Vitamin C, stir and dissolve under nitrogen atmosphere to make the solution clear, add the reserve solution at a drop rate of 0.35 ml / s, homogenize twice with a homogenizer at 80MPa and 160MPa, take it out after 20min each time, and put it in the air Spray drying under the drying parameters of 170°C and air outlet of 90°C, collect the spray powder and sieve to obtain the finished product.

[0036] The following is the performance test of the obtained water-soluble reduced coenzyme Q10 composition: the method for determining the content of the water-soluble reduced coenzyme Q10 composition mainly adopts high-performance liqu...

Embodiment 2

[0054] Prepared by direct heating and melting of reduced coenzyme Q10 and emulsifier:

[0055] Take 10g of reduced coenzyme Q10, 80g of pure gum, 30g of sucrose fatty acid ester and 0.5g of vitamin E, dissolve in 200ml of water, heat to 60°C to melt, and then use a homogenizer to homogenize twice at 100MPa and 180MPa, each time Take it out after 15 minutes, spray dry under the drying parameters of 170°C air inlet and 90°C air outlet, collect the spray powder and sieve to get the finished product.

[0056] The performance testing method of the obtained water-soluble reduced coenzyme Q10 composition is the same as that in Example 1.

[0057] 1. Stability test

[0058] The detection value of the water-soluble reduced coenzyme Q10 composition in this experiment is 0 under chromatographic conditions (C18 column, mobile phase: methanol: absolute ethanol = 1:1, detection wavelength 275nm), which proves that the water-soluble reduced coenzyme Q10 composition in this experiment The p...

Embodiment 3

[0074] Prepared by first dissolving reduced coenzyme Q10 in an organic solvent and then mixing it with an emulsifier:

[0075] Take 15g of reduced coenzyme Q10, 20g of sorbitol fatty acid ester and 20g of poloxamer, dissolve in 150ml of ethyl acetate, stir to form a clear and transparent solution as a spare solution; take 3000ml of hot water at 40°C, add 60g of lactose and 40g of Gum Arabic, stirring and dissolving to make the solution clear, add the reserve solution at a dropping rate of 0.5 ml / s, homogenize it with a homogenizer at 70MPa for 75 minutes, and take it out. Then spray dry, collect the spray powder and sieve to get the finished product.

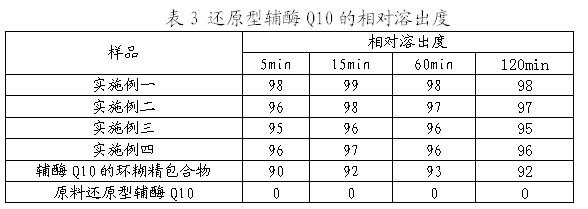

[0076] The performance test method of the obtained water-soluble reduced coenzyme Q10 composition is the same as in Example 1, and the results are shown in Table 1, Table 2 and Table 3.

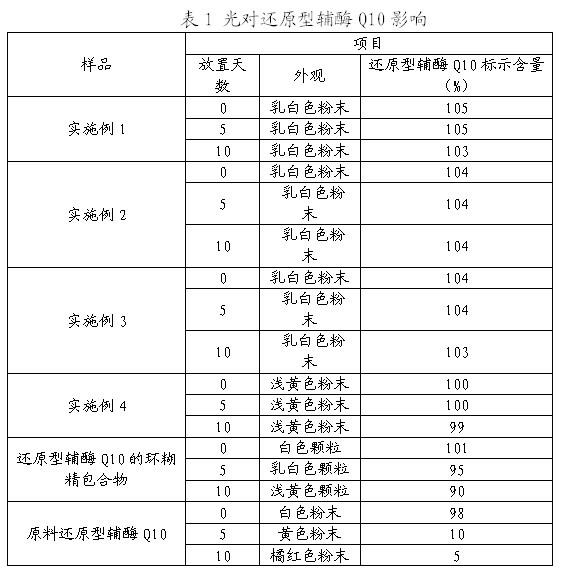

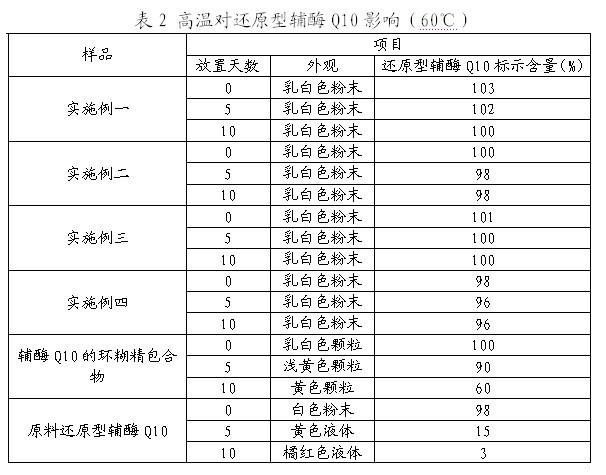

[0077] Table 1 shows that light has a greater impact on coenzyme Q10. The water-soluble reduced coenzyme Q10 composition in Example 3 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com