Low-smoke and zero-halogen inflaming retarding glass fiber reinforced polycarbonate composite material and preparation method thereof

A technology of polycarbonate and composite materials, applied in the field of polymer materials, can solve the problems of non-environmental protection, safety, processing difficulties, poor fluidity, etc., and achieve the effects of excellent impact toughness, good die fluidity, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

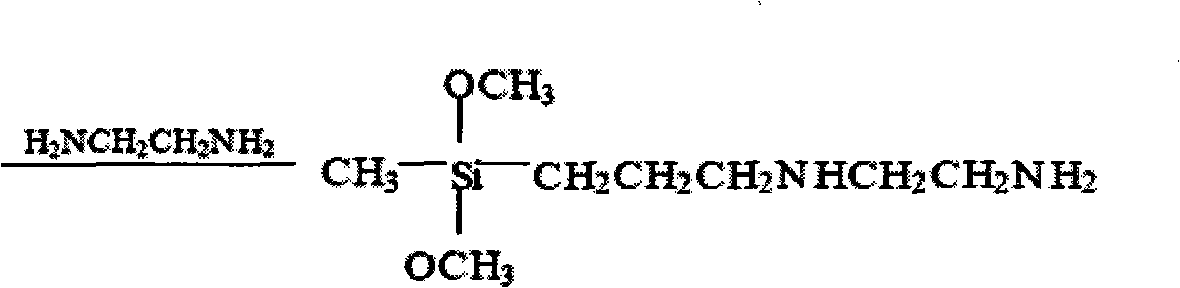

[0028] The preparation method of self-made silane coupling agent:

[0029] raw material:

[0030] Methyldichlorosilane: purity 98.2%, Xinghuo Chemical Plant

[0031] Propyl chloride: purity 98.5%, Hunan Yueyang Chemical

[0032] Anhydrous methanol, analytically pure, Beijing Chemical Plant

[0033] Ethylenediamine: analytically pure, Shenyang Xinxing Reagent Factory

[0034] Chloroplatinic acid: chemically pure, Shenyang Keda Reagent Factory

[0035] Composite path:

[0036] CH 2 =CHCH 2 Cl+CH 3 SiHCl 2 ——CH 3 (ClCH 2 CH 2 CH 2 ) SiCl 2 (Intermediate I)

[0037] (Intermediate II)

[0038]

[0039] Basic method: Using methyl dichlorosilane and allyl chloride as raw materials and chloroplatinic acid as a catalyst, an intermediate I was synthesized: methyl (γ-chloropropyl) dichlorosilane, which was combined with Ethylenediamine reacts to give the product.

[0040] Synthesis of Intermediate I: In a 250ml three-neck flask equipped with a thermometer, a constan...

Embodiment 1

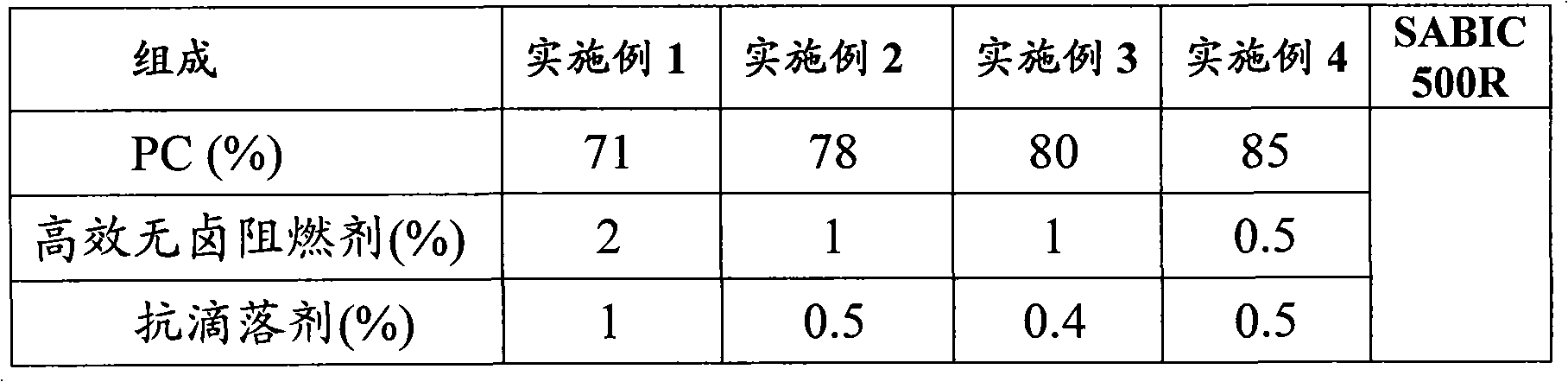

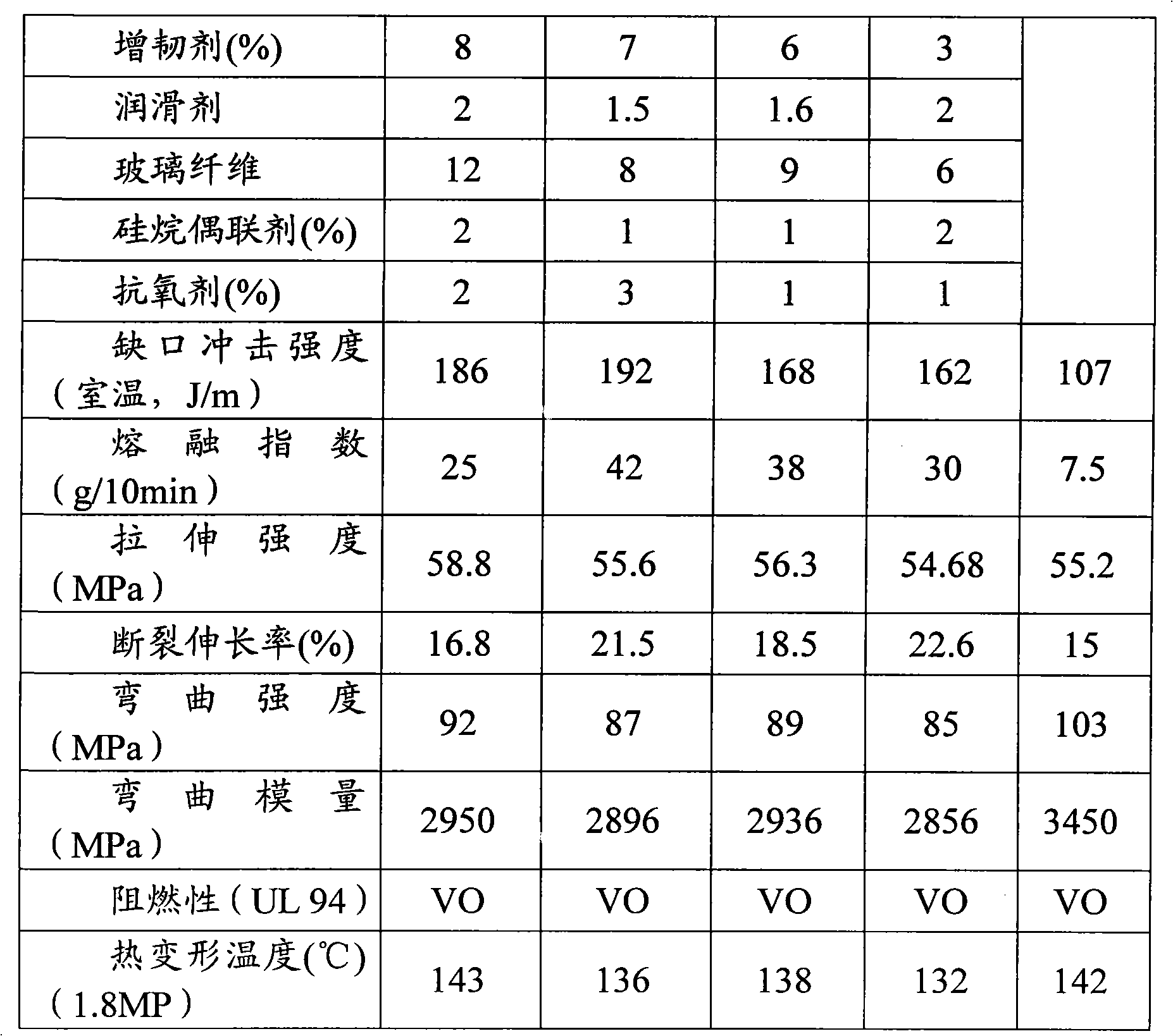

[0044] Add 2% of high-efficiency halogen-free flame retardant, 2% of silane coupling agent, 1% of flame retardant and anti-dripping agent, 8% of toughening agent, 2% of lubricant and 2% of antioxidant into the high-speed batch mixer and stir for 5 Minutes, each component is weight percent. Then add the baked 71% PC, then stir together for 15 minutes, and set aside. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate, and add 12% glass fiber from the side feed. The section temperature is 240-260°C, the mold temperature is 60-100°C, the residence time is 1-2 minutes, and the pressure is 10-15MPa; the glass fiber is added from the side feeding port, the main screw speed is 400-500r / min, and the feeding speed is 40- 60r / min.

[0045] In this embodiment, the toughening agent is an MBS core-shell impact modifier or a silicon-modified acrylic impact modifier. Antioxidant is tetrakis [β-propionic acid]quaternary tetraethylene glycol ester or triphosphite....

Embodiment 2

[0048] Add 1% of high-efficiency halogen-free flame retardant, 3% of silane coupling agent, 0.5% of flame retardant and anti-dripping agent, 7% of toughening agent, 1.5% of lubricant and 1% of antioxidant into a high-speed batch mixer and stir for 5 Minutes, each component is weight percent. Then add the baked 78% PC, then stir together for 15 minutes, and set aside. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate, and add 8% glass fiber from the side feed. The section temperature is 240-260°C, the mold temperature is 60-100°C, the residence time is 1-2 minutes, and the pressure is 10-15MPa; the glass fiber is added from the side feeding port, the main screw speed is 400-500r / min, and the feeding speed is 40- 60r / min.

[0049] In this embodiment, the toughening agent is an MBS core-shell impact modifier or a silicon-modified acrylic impact modifier. Antioxidant is tetrakis [β-propionic acid]quaternary tetraethylene glycol ester or triphosphite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com