Method for preparing aqueous gel/nano hydroxyapatite composite scaffold for hard tissue repair

A technology of hydroxyapatite and composite scaffold, which is applied in the field of biomedical material science, can solve the problems of difficult tissue penetration and insufficient material performance, and achieve the effects of good induction of bone formation, improvement of bone repair effect, and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

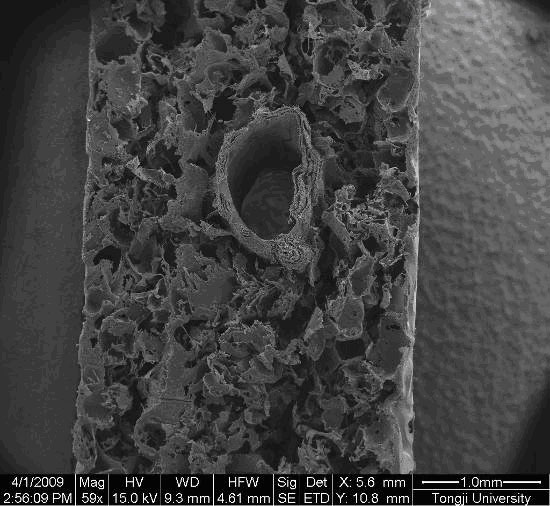

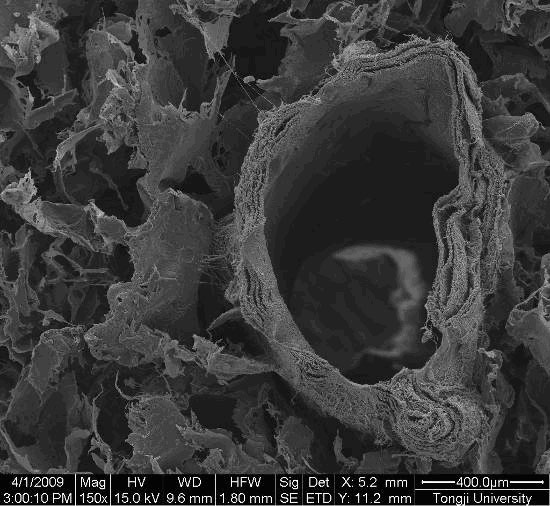

[0026] Step 1: Dissolve collagen and PLA with a concentration of 8% in hexafluoroisopropanol at a mass ratio of 1:2. After completely dissolving, perform electrospinning. The spinning parameters are: voltage 18kv, speed 500r / min , with a height of 10 cm, prepare small blood vessels with a diameter of 0.5 mm, cut into small sections with a length of 2 cm, and set aside;

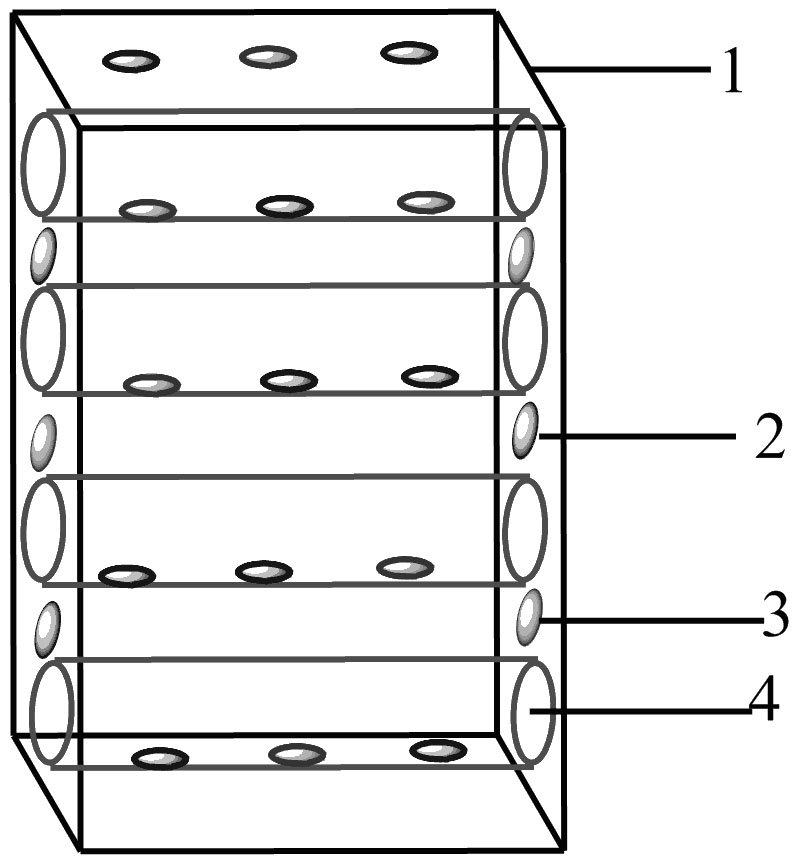

[0027] Step 2: Mix PLA and PCL at a mass ratio of 1:1, add sodium chloride after dissolving chloroform, let it stand for 1 hour, filter with salt to make holes, add small blood vessels and heat press to form a degradable three-dimensional scaffold with reserved channels Material;

[0028] Step 3: Dissolve 1g of degradable water-soluble polymer PEG2000 in 10ml of water, dissolve 0.1g of α-cyclodextrin and 0.005g of nano-hydroxyapatite in 10ml of water, ultrasonically disperse for 15 minutes, and mix the two solutions by 1: 1 volume ratio mixed, immediately injected into the reserved channel of the scaffold mat...

Embodiment 2

[0032] Step 1: Dissolve collagen and PLA with a concentration of 8% in hexafluoroisopropanol at a mass ratio of 1:3. After completely dissolving, electrospinning is performed. The spinning parameters are: voltage 16kv, speed 600r / min , with a height of 12 cm, prepare small blood vessels with a diameter of 1.0 mm, cut into small sections with a length of 2 cm, and set aside;

[0033] Step 2: Mix PLA and PCL at a mass ratio of 1:1, add sodium chloride after dissolving chloroform, let it stand for 1 hour, filter with salt to make holes, add small blood vessels and heat press to form a degradable three-dimensional scaffold with reserved channels Material;

[0034] Step 3: Dissolve 1g of degradable water-soluble polymer PEG2000 in 10ml of water, dissolve 0.1g of α-cyclodextrin and 0.005g of nano-hydroxyapatite in 10ml of water, ultrasonically disperse for 15 minutes, and mix the two solutions by 1: 1 volume ratio mixed, immediately injected into the reserved channel of the scaffol...

Embodiment 3

[0038] Step 1: Dissolve collagen and PLA with a concentration of 8% in hexafluoroisopropanol at a mass ratio of 1:2. After completely dissolving, perform electrospinning. The spinning parameters are: voltage 18kv, speed 500r / min , with a height of 10 cm, prepare small blood vessels with a diameter of 0.5 mm, cut into small sections with a length of 2 cm, and set aside;

[0039] Step 2: Mix PLA and PCL at a mass ratio of 1:2, add sodium chloride after dissolving chloroform, let it stand for 1 hour, filter with salt to make holes, add small blood vessels and heat press to form a degradable three-dimensional scaffold with reserved channels Material;

[0040] Step 3: Dissolve 1g of degradable water-soluble polymer PEG-PCL-PEG in 10ml of water, dissolve 0.1g of α-cyclodextrin and 0.005g of nano-hydroxyapatite in 10ml of water, and ultrasonically disperse for 15 minutes. The solution is mixed according to a volume ratio of 1:1, and immediately injected into the reserved channel of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com