Aluminium silicate nano composite insulation coating and preparation method thereof

A nano-composite and heat-insulating coating technology, applied in coatings and other directions, can solve problems such as poor heat-insulation effect and complex production process, and achieve the effects of improving heat-insulation properties, simple preparation process, and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

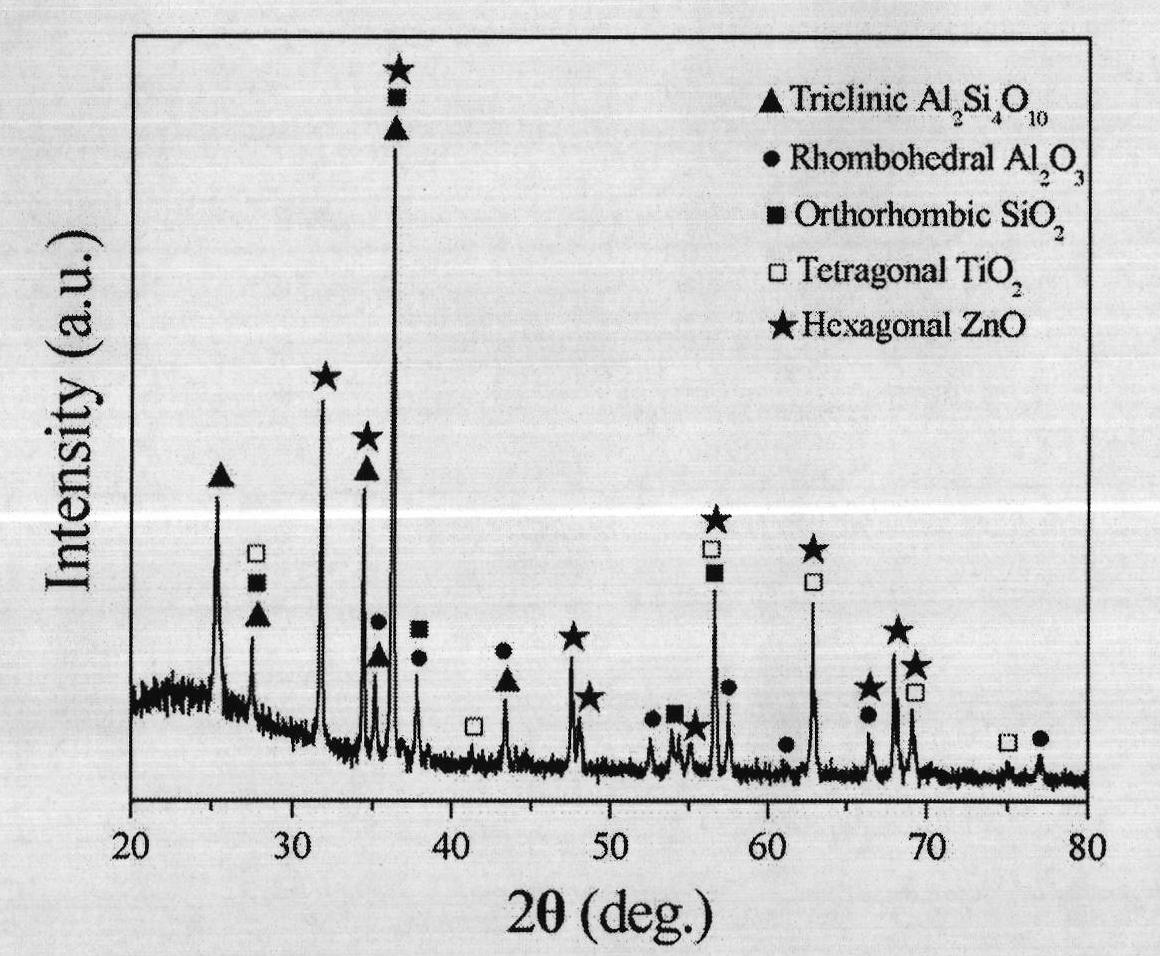

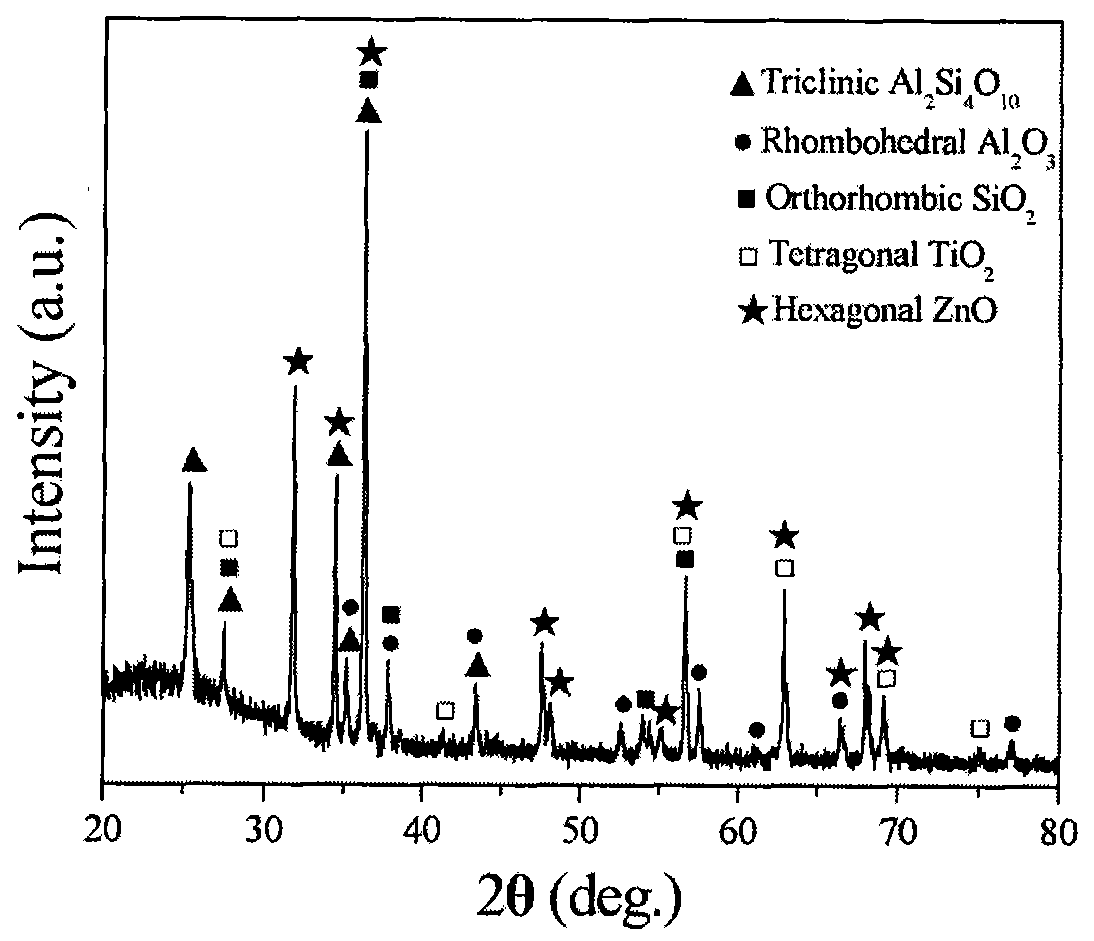

[0025] Embodiment 1: Determining the mass percentage composition of aluminum silicate nanocomposite thermal insulation coating is as follows: nano aluminum silicate 15%, vinegar acrylic emulsion 25%, water 41%, nano silica 6%, nano alumina 3%, nano oxide 3% zinc, 3% nano-titanium oxide, 0.5% film-forming aid, 1% defoamer, 1% wetting and dispersing agent, 1% antifreeze, and 0.5% leveling agent. The preparation process is as follows: Stir water, nano-aluminum silicate, wetting and dispersing agent, and half of the defoamer at high speed for 2 hours under low-speed stirring to fully disperse them, then add other inorganic nano-powders under stirring, and disperse Stir at high speed on the machine for 3 hours, and disperse it evenly by high-speed shearing. Then slowly add the emulsion dropwise at a low stirring speed, then add the remaining defoamer, film-forming aid, antifreeze, and leveling agent and stir for 3 hours at a low speed, and finally pack into a can to obtain the fini...

Embodiment 2

[0026] Embodiment 2: Determining the mass percentage composition of aluminum silicate nano-composite thermal insulation coating is as follows: 20% of nano-aluminum silicate, 25% of styrene-acrylic emulsion, 38% of water, 5% of nano-silica, 2% of nano-alumina, 3% zinc, 3% nano-titanium oxide, 0.5% film-forming aid, 1% defoamer, 1% wetting and dispersing agent, 1% antifreeze, and 0.5% leveling agent. The preparation process is as follows: Stir water, nano-aluminum silicate, wetting and dispersing agent, and half of the defoamer at high speed for 2 hours under low-speed stirring to fully disperse them, then add other inorganic nano-powders under stirring, and disperse Stir at high speed on the machine for 2 hours, and disperse it evenly by high-speed shearing. Then slowly add the emulsion dropwise at a low stirring speed, then add the remaining defoamer, film-forming aid, antifreeze, and leveling agent and stir for 4 hours at a low speed, and finally pack into a can to obtain the...

Embodiment 3

[0027] Example 3: 25% of nano-aluminum silicate, 23% of vinegar-acrylic emulsion, 38% of water, 4% of nano-silica, 2% of nano-alumina, 2% of nano-zinc oxide, 2% of nano-titanium oxide, film-forming aid 0.5%, defoamer 1%, wetting and dispersing agent 1%, antifreeze 1%, leveling agent 0.5%. The preparation process is as follows: Stir water, nano-aluminum silicate, wetting and dispersing agent, and half of the defoamer at high speed for 2 hours under low-speed stirring to fully disperse them, then add other inorganic nano-powders under stirring, and disperse Stir at high speed on the machine for 3 hours, and disperse it evenly by high-speed shearing. Then slowly add the emulsion dropwise at a low stirring speed, then add the remaining defoamer, film-forming aid, antifreeze, and leveling agent and stir for 6 hours at a low speed, and finally pack into a can to obtain the finished coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com