Chitosan/ Curdlan blended membrane material and preparation method thereof

A technology of chitosan and blended membranes, applied in the field of medical engineering, can solve the problems of unfavorable manufacturing of artificial skin, not very obvious, water absorption resistance, etc., achieve good blood coagulation function, reduce costs, and resist infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

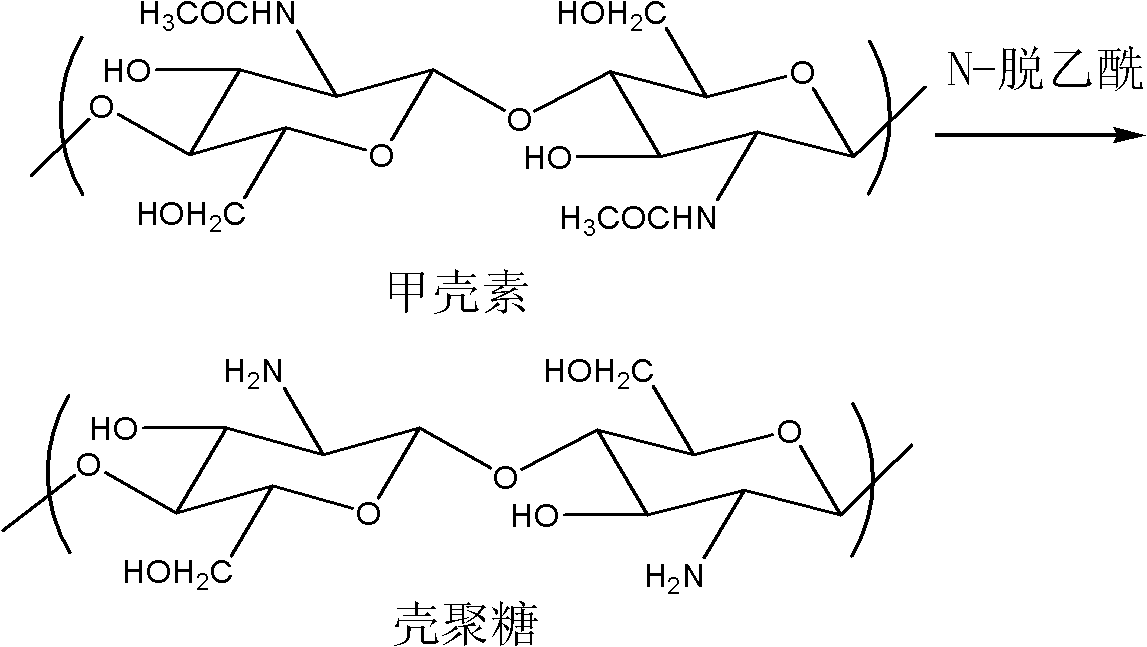

Method used

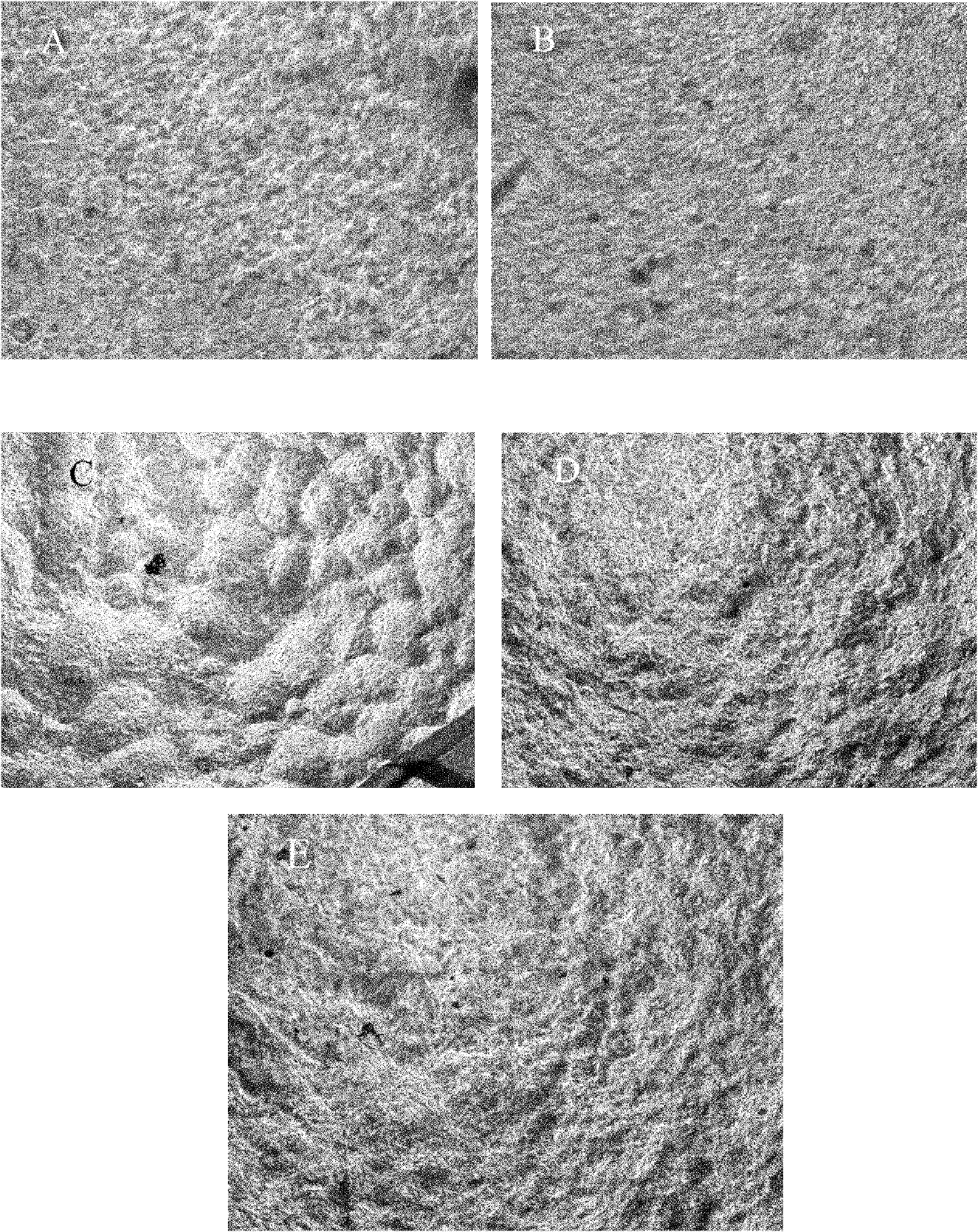

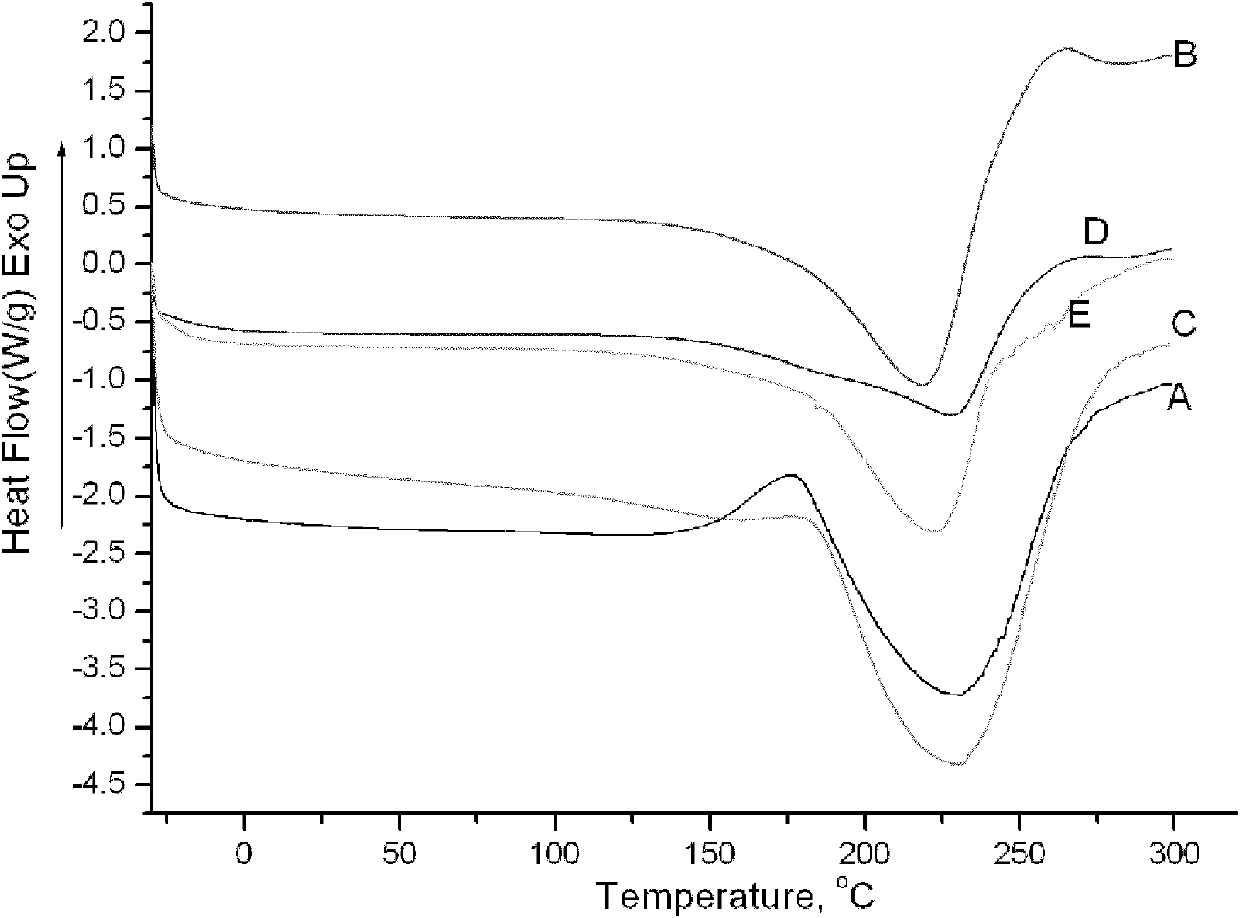

Image

Examples

Embodiment 1

[0051] Example 1: The chitosan / codak blend film to be prepared, the specific weight percentage is: chitosan / codak = 1 / 5, glycerol accounts for 5%, and the preparation process is as follows:

[0052] (1) Configuration of chitosan solution: Dissolve 50.00 mg of chitosan (deacetylation degree of 50%, molecular weight of 150,000) in 5.00 mL of 1% dilute acetic acid solution to prepare 10.00 mg / mL chitosan Sugar and acetic acid solution, stir well.

[0053] (2) Preparation of Curdlan solution: Dissolve 250.00 mg of Curdlan in 25.00 mL of deionized water, stir at room temperature to fully disperse Curdlan in the water, and prepare a 10.00 mg / mL Curdlan aqueous solution to form a uniform and stable aqueous dispersion.

[0054] (3) Mix the two solutions in step 1) and step 2), add 11.9 μL of glycerol (ρ=1.2633g / mL), control the temperature within the range of 30°C, and mechanically stir to make the mixture evenly mixed to form a uniform and stable of the dispersion.

[0055] (4) Tak...

Embodiment 2

[0057] Example 2: The chitosan / codak blend film to be prepared, the specific weight percentage is: chitosan / codak = 1 / 1, glycerol accounts for 7.5%, and the preparation process is as follows:

[0058] (1) Configuration of chitosan solution: Dissolve 225.00 mg of chitosan (deacetylation degree of 65%, molecular weight of 400,000) in 15.00 mL of 3% dilute acetic acid solution to prepare 15.00 mg / mL of chitosan Sugar and acetic acid solution, stir well.

[0059] (2) Preparation of Curdlan solution: Dissolve 225.00 mg Curdlan in 15.00 mL of 3% sodium hydroxide, stir at room temperature to fully dissolve Curdlan in the dilute alkali solution, and prepare a 15.00 mg / mL Curdlan alkali solution to form a stable solution .

[0060] (3) Mix the two solutions in step 1) and step 2), add 26.7 μL of glycerol (ρ=1.2633 g / mL), control the temperature within the range of 75°C, and mechanically stir to make the mixture evenly mixed to form a uniform and stable of the dispersion.

[0061] (4...

Embodiment 3

[0063] Example 3: The chitosan / codak blend film to be prepared, the specific weight percentage is: chitosan / codak=2 / 1, glycerol accounts for 8.125%, and the preparation process is as follows:

[0064] (1) Configuration of chitosan solution: Dissolve 325.00 mg of chitosan (deacetylation degree of 76%, molecular weight of 670,000) in 20.00 mL of 3.50% dilute acetic acid solution to prepare 16.25 mg / mL of chitosan Sugar and acetic acid solution, stir well.

[0065] (2) Preparation of Curdlan solution: Dissolve 162.50 mg of Curdlan in 10.00 mL of 3.5% trisodium phosphate, stir at room temperature to fully dissolve Curdlan in the dilute alkali solution, and prepare a 16.25 mg / mL Curdlan alkali solution to form a uniform solution Stable colloidal solution.

[0066] (3) Mix the two solutions in step 1) and step 2), add 31.3 μL of glycerol (ρ=1.2633 g / mL), control the temperature within the range of 90°C, and mechanically stir to make the mixture evenly mixed to form a uniform and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com