Method for dehydrating ethanol

A technology of ethanol dehydration and ethanol aqueous solution, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of high reaction temperature, low catalyst activity and stable Sexual issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

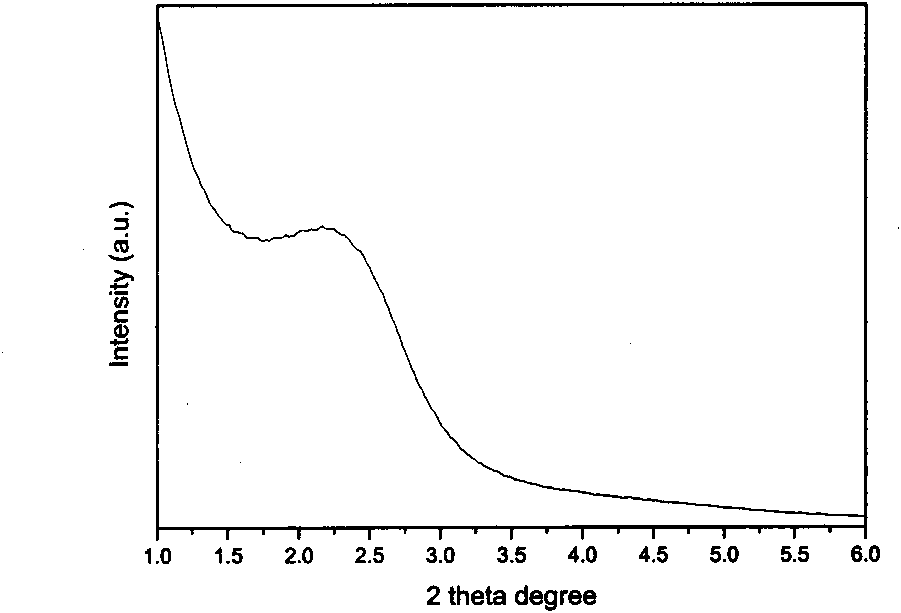

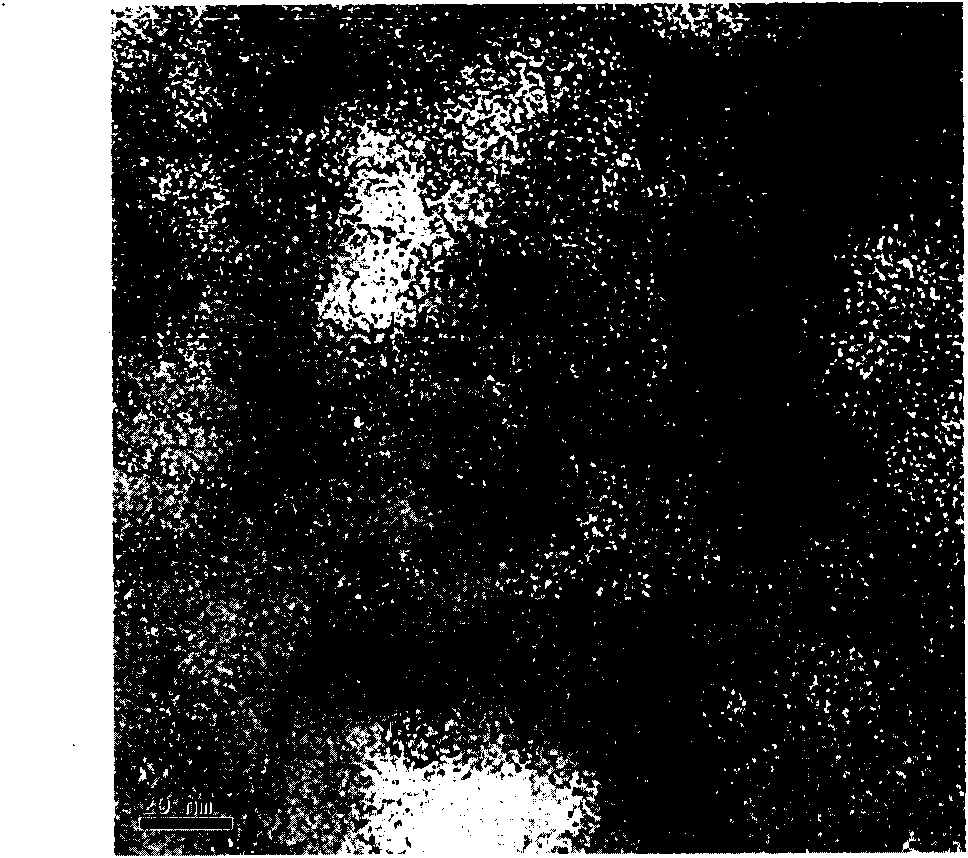

[0019] 6.2 g of Zr(NO 3 ) 4 ·5H 2 O was dissolved in 208 grams of deionized water, and after the dissolution was complete, 16 grams of cetyltrimethylammonium bromide (CTAB) was added, fully stirred to dissolve it, and after the solution was clarified, 80 grams of ethyl orthosilicate was added, Zr: Si: CTAB (mole) = 1: 24.5: 3, under stirring conditions, add concentrated ammonia water dropwise to pH = 10, continue to stir for 2 hours, age for 12 hours, filter the sample and wash it with deionized water until there is no impurity ion Dry at 100°C to obtain mesoporous ZrO 2 -SiO 2 carrier.

Embodiment 2

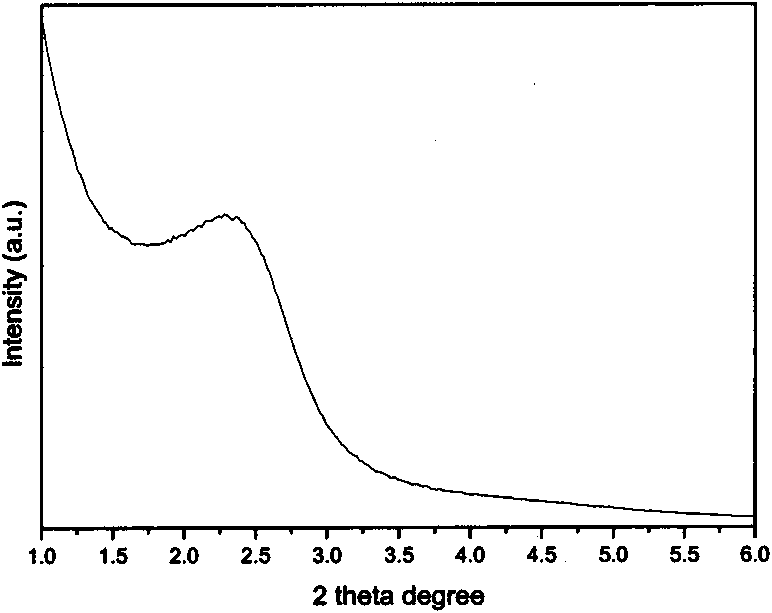

[0021] Press each step and condition of [embodiment 1], just use ZrOCl 2 , silica sol, polyoxypropylene polyoxyethylene copolymer (P123), make Zr: Si: P123 (mol) = 1: 11.3: 0.5, aging for 24 hours.

Embodiment 3

[0023] Press each step and condition of [embodiment 1], just use ZrOCl 2 , water glass, P123, make Zr: Si: P123 (mol) = 1: 27.6: 1, aging for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com