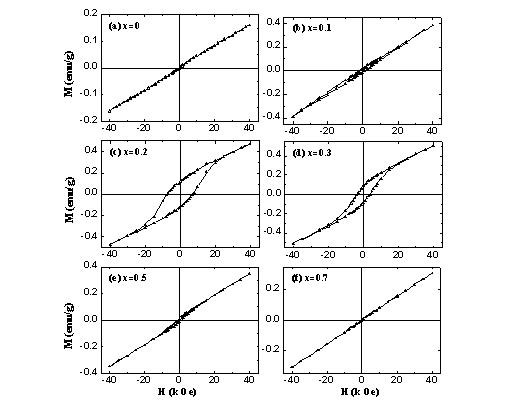

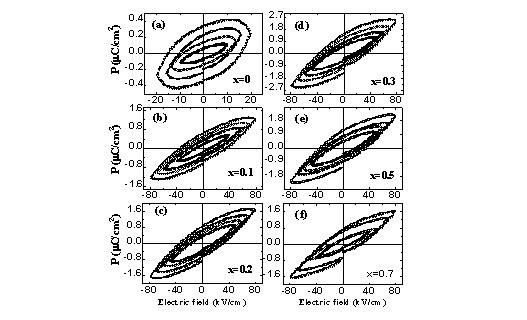

BiFeO3-Bi0.5Na0.5TiO3 base multiferroic solid solution ceramic and preparation method thereof

A solid solution and ceramic technology, applied in the field of information functional materials, can solve the problems that hinder the development of related devices of multiferroic materials, low Curie temperature and Neel temperature, and difficult synthesis of single-phase materials, so as to achieve short cycle time and low leakage current, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of pure BiFeO by sol-gel method using citric acid as complexing agent 3 ceramics. In the first step, weigh 0.04mol of citric acid and put it into a 100mL beaker, add 20mL of deionized water, and dissolve it under ultrasonic dispersion to form a transparent solution; weigh 0.02mol of bismuth nitrate and add it to the above solution to dissolve while stirring continuously, and wait to dissolve Finally, weigh 0.02mol ferric nitrate and add to the above solution and dissolve. Under the condition of constant stirring, adjust the pH value to 7~7.5 with ammonia water, and age the mixed solution for 3 hours. Step two, in a water bath at 80 o C Evaporate the solution to dryness to remove water, in the oven at 130 oC Dry until a black xerogel forms. The third step is to grind the xerogel in the air at 500 o C heat treatment for 4 hours, get rid of organic matter to obtain the precursor powder, then the precursor powder is ground, pressed into tablets, 800 o C s...

Embodiment 2

[0031] Preparation of 0.9BiFeO by Sol-Gel Method Using Citric Acid as Complexing Agent 3 -0.1Bi 0.5 Na 0.5 TiO 3 Ceramics, the first step, weigh 0.04mol citric acid into a 100mL beaker, add 20mL deionized water, dissolve under ultrasonic dispersion, and form a transparent solution; use a graduated straw to take 0.02mol analytically pure butyl titanate, in Add it into the above citric acid solution under constant stirring, ultrasonically disperse for 30 minutes, and form a transparent solution; then, weigh 0.01mol bismuth nitrate and 0.01mol sodium nitrate, add to the above solution to dissolve, add deionized water to obtain 40ml solution, and become A solution . Weigh 0.04mol of citric acid and put it into another 100mL beaker, add 20mL of deionized water, and dissolve under ultrasonic dispersion to form a transparent solution; weigh 0.02mol of bismuth nitrate and add it to the above solution to dissolve under constant stirring. After dissolving, Weigh 0.02mol ferric nitra...

Embodiment 3

[0035] Preparation of 0.8BiFeO by Sol-Gel Method Using Citric Acid as Complexing Agent 3 -0.2Bi 0.5 Na 0.5 TiO 3 Ceramics, the first step, weigh 0.04mol of citric acid into a 100mL beaker, add 20mL of deionized water, dissolve under ultrasonic dispersion, and form a transparent solution; weigh 0.02mol of analytically pure butyl titanate with a graduated straw, Add it into the above citric acid solution under constant stirring, ultrasonically disperse for 30 minutes, and form a transparent solution; then, weigh 0.01mol bismuth nitrate and 0.01mol sodium nitrate, add to the above solution to dissolve, add deionized water to obtain a 40ml solution, and become A solution. Weigh 0.04mol of citric acid and put it into another 100mL beaker, add 20mL of deionized water, and dissolve under ultrasonic dispersion to form a transparent solution; weigh 0.02mol of bismuth nitrate and add it to the above solution to dissolve under constant stirring. After dissolving, Weigh 0.02mol ferric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com