Heat supply system and method

A heating system and heat storage technology, which is applied to heating systems, solar heating systems, and central heating, and can solve problems such as large power consumption, power consumption, and large investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, Features and their functions are described in detail below.

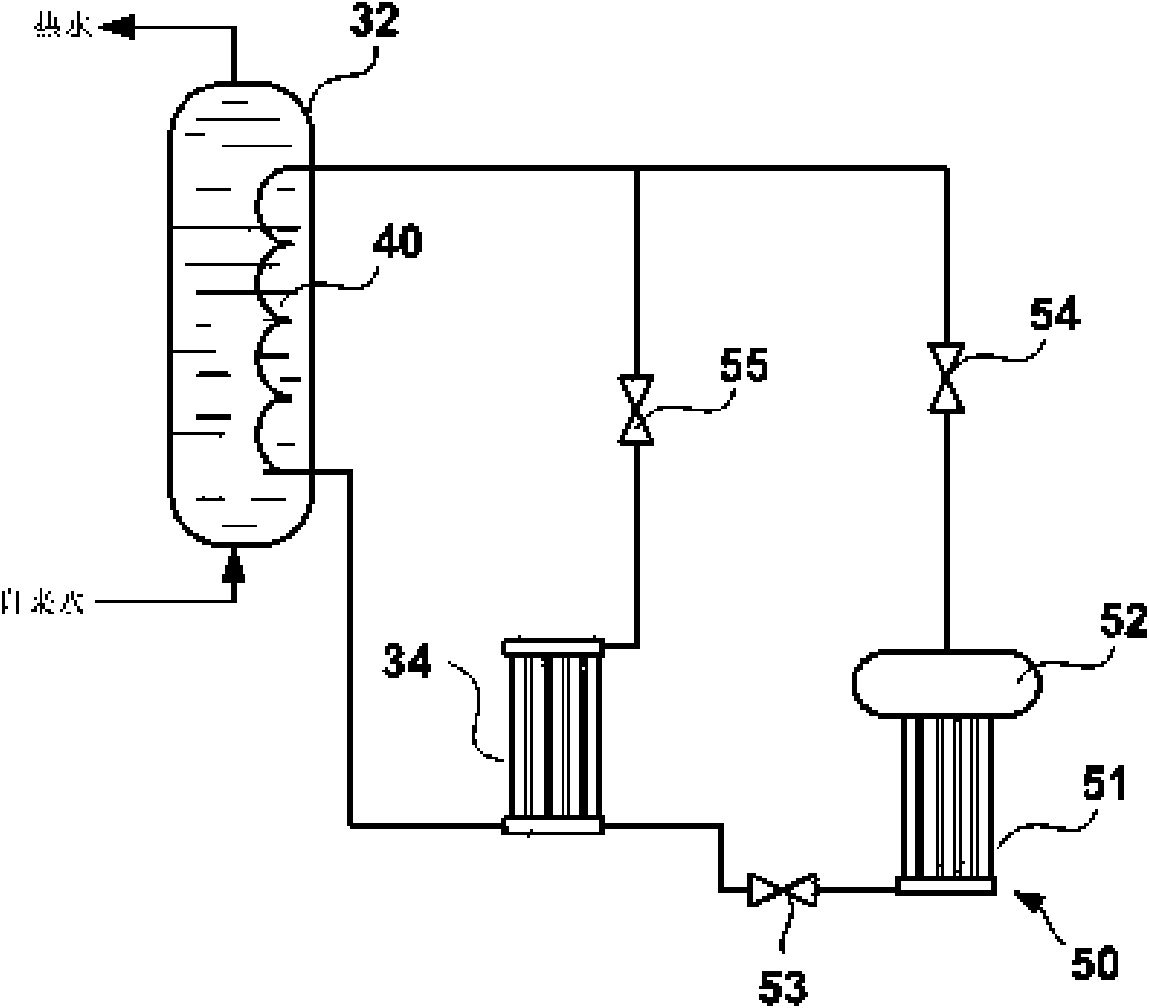

[0024] see image 3Shown is the heating system of Embodiment 1 of the present invention, including an energy storage tank 32 , a main solar heat collector 34 and a high-pressure heat storage device 50 . The energy storage tank 32 is provided with an energy storage heat exchange coil 40 , and the energy storage heat exchange coil 40 is connected with the main solar heat collector 34 through pipes to form a circulation loop in which the refrigerant circulates. The energy storage box 32 is filled with a heat storage agent with a phase transition temperature of 0-40°C. The heat storage agent is a latent heat storage agent, which can be water, lithium nitrate hydrate, calcium chloride hydrate, disodium hydrogen phosphate hydrate, sodium sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com