A Heat Pipe Vapor Compression Composite Refrigeration System with Ejector for Air Conditioning

A refrigeration system and vapor compression technology, applied in air conditioning systems, household heating, heating methods, etc., can solve the problems of increasing the risk of refrigerant leakage, limited refrigerant driving force, failure of natural cooling methods, etc., and achieve good energy saving effect, clear pertinence, effect of good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

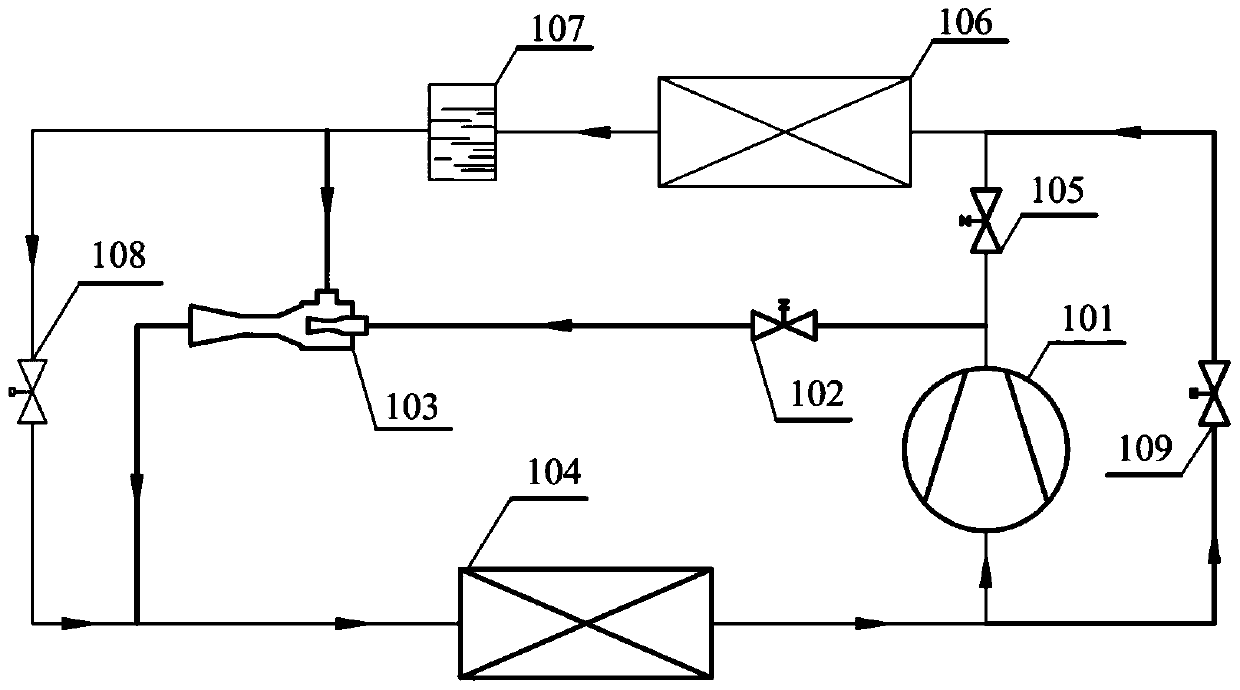

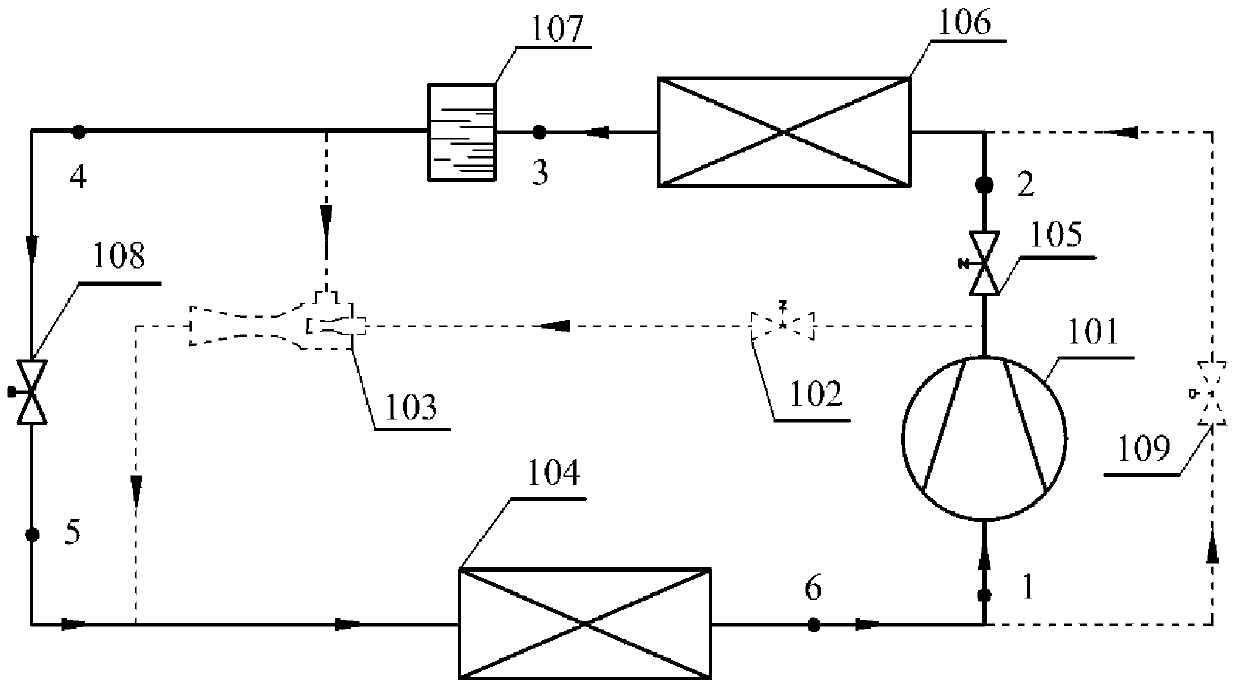

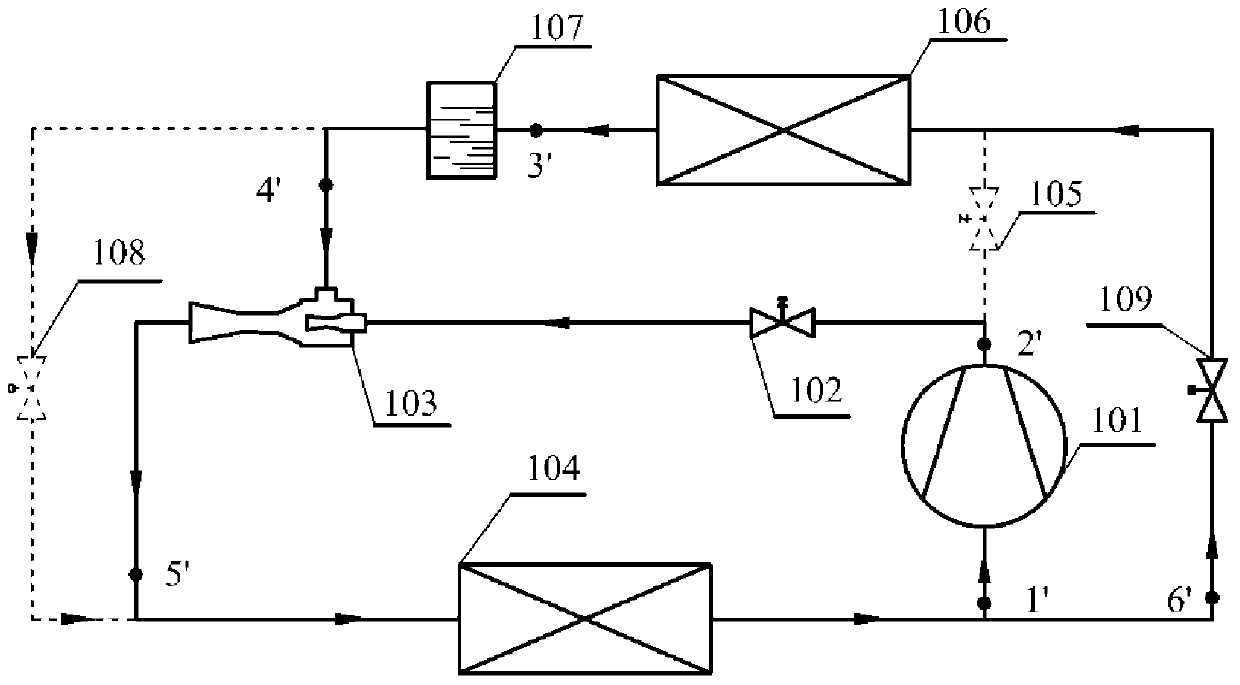

[0024] Such as figure 1 As shown, in this embodiment, a heat pipe vapor compression compound refrigeration system for air conditioning with an ejector is used. The outlet of the frequency conversion compressor 101 is divided into two paths, and one path is connected to the nozzle inlet of the ejector 103 after passing through the first flow regulating valve 102. The outlet of the ejector 103 is connected with the inlet of the evaporator 104; the other path is connected with the inlet of the condenser 106 after the solenoid valve 105, and the outlet of the condenser 106 is connected with the inlet of the liquid storage device 107, and the outlet of the liquid storage device 107 is divided into two One way is connected to the inlet of the evaporator 104 after passing through the electronic expansion valve 108, and the other is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com