Sn-doped ZnO superfine nanowires and synthesis method thereof

A synthesis method and fatty acid zinc technology, applied in the field of nanomaterials, can solve the problems of poor doping uniformity, complicated process, limited application, etc., and achieve the effects of easy industrial production, strong quantum confinement effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Take by weighing 1mmol zinc stearate, 0.1mmol tin stearate (molar ratio is 10:1), 7mmol oleylamine and 10ml 1-octadecene are placed in a 50ml reaction flask, under an inert protective atmosphere, Magnetic stirring was used to raise the temperature to 140° C., and then keep the temperature for 20 minutes.

[0021] 2) Raise the temperature to 340° C. under an inert protective atmosphere, keep it warm for 30 minutes, cool the reaction solution to room temperature with a water bath, and centrifuge the reaction mixture to obtain Sn-doped ZnO ultrafine nanowires.

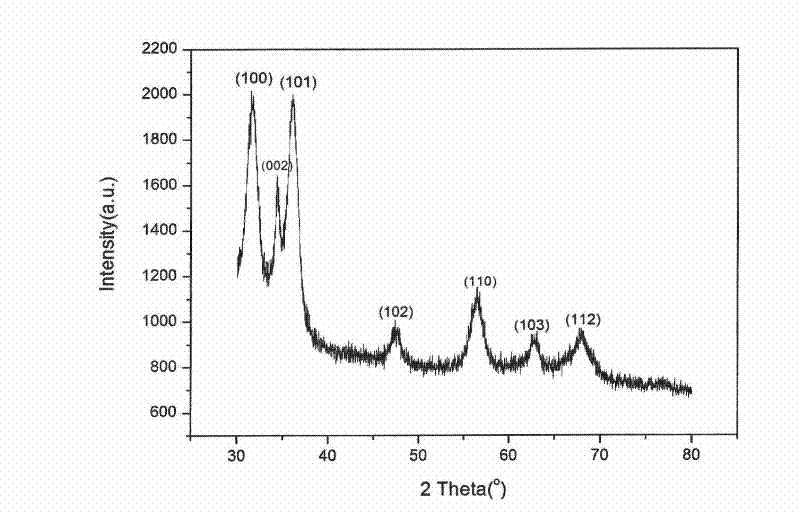

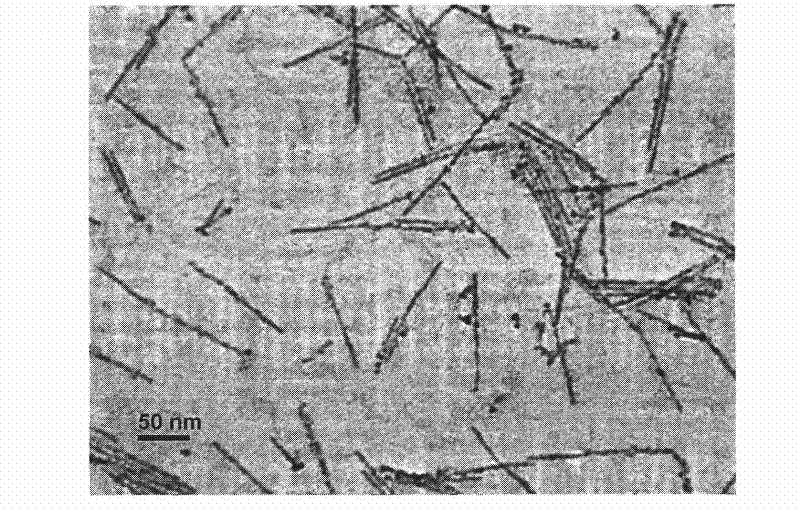

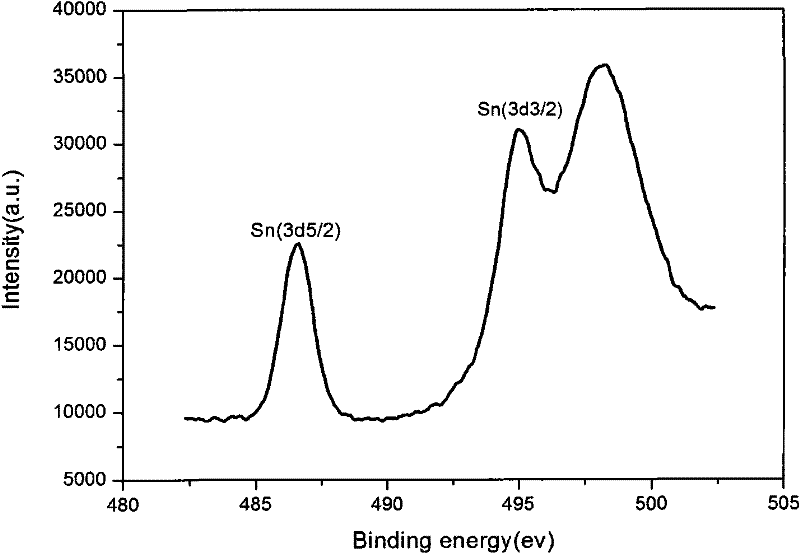

[0022] After the green product obtained is dried, carry out XRD test, test result sees figure 1 . figure 1 The peaks in are all the main peak positions of the wurtzite ZnO phase, which proves that the obtained product has a wurtzite structure; the TEM electron microscope photo of the product is shown in figure 2 , it can be seen from the figure that the diameter of the nanowire is 3-5 nanometers and the lengt...

Embodiment 2

[0024] 1) Weigh 1mmol of zinc stearate, 0.2mmol of tin citrate (5:1 molar ratio), 10mmol of octadecylamine and 10ml of n-octyl ether in a 50ml reaction flask, and then keep warm for 10 minutes.

[0025] 2) Under the protection of an inert atmosphere, raise the temperature to 250° C., keep it warm for 60 minutes, cool the reaction solution to room temperature with a water bath, and centrifuge the reaction mixture to obtain Sn doped particles with a diameter of 2 to 6 nanometers and a length of 100 to 200 nanometers. doped ZnO ultrafine nanowires.

Embodiment 3

[0027] 1) Weigh 1mmol of zinc stearate, 0.3mmol of tin citrate (molar ratio is 10:3), 5mmol of dodecylamine and 12ml of diphenyl ether in a 50ml reaction flask, under the protection of an inert atmosphere, magnetically stir and heat up to 150°C, and then keep warm for 30 minutes.

[0028] 2) Under the protection of an inert atmosphere, raise the temperature to 210° C., keep it warm for 20 minutes, cool the reaction solution to room temperature with a water bath, and centrifuge the reaction mixture to obtain Sn doped particles with a diameter of 2 to 4 nanometers and a length of 100 to 300 nanometers. doped ZnO ultrafine nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com