Nanocomposite nickel-plated coating material and preparation method and application thereof

A nano-composite and nickel-plating technology, which is applied to surface coating materials and fields, can solve the problems of high film preparation cost, harsh process conditions and high price, and achieve the effects of low friction coefficient, low preparation cost and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

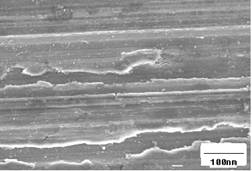

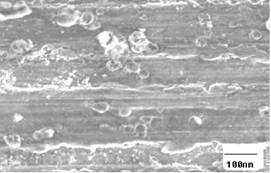

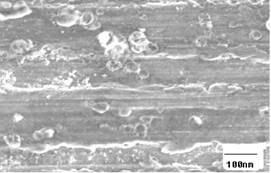

Image

Examples

Embodiment 1

[0033] After the titanium alloy is degreasing, alkaline etching and acid etching, it is plated with nanometer rare earth oxide and carbon on the titanium alloy substrate by secondary zinc dipping and pre-plating electroless nickel. Ni-based composite coating of nanotubes.

[0034] The plating method is as follows:

[0035] (1) Preparation of chemical plating solution

[0036] Its composition is: nickel sulfate 26g / L, sodium hypophosphite 18g / L, sodium acetate 22g / L, sodium citrate 28g / L, lactic acid 19g / L;

[0037] 18g / L nano rare earth oxides and 10g / L carbon nanotubes were prepared by emulsion method; pH value of plating solution was adjusted with acetic acid or ammonia water, pH=4.5

[0038] The nanometer rare earth oxide is nanometer lanthanum oxide; the particle diameter of nanometer lanthanum oxide is about 65 nanometers and the particle diameter of carbon nanotubes is about 65 nanometers;

[0039] (2) Degreasing, activation and pre-plating of plated parts;

[0040] ...

Embodiment 2

[0044] After degreasing and acid etching, the amorphous alloy is coated with a Ni-based composite coating containing nanometer rare earth oxides and carbon nanotubes on a zirconium-based amorphous alloy substrate by a nanochemical composite plating method. The plating method is as follows:

[0045] (1) Prepare a nanochemical composite plating solution, which is composed of: nickel sulfate 24g / L, sodium hypophosphite 26g / L, sodium acetate 22g / L, sodium citrate 34g / L, lactic acid 24g / L, emulsion 16g / L of nano-rare earth oxides and 12g / L of carbon nanotubes prepared by the method; the pH value of the plating solution was adjusted with acetic acid (ammonium sulfate) and sodium acetate (ammonia), pH=8;

[0046] The nanometer rare earth oxide is nanometer cerium oxide; the particle diameter of nanometer cerium oxide is about 75 nanometers, and the particle diameter of carbon nanotubes is about 75 nanometers;

[0047] (2) Degreasing, activation and pre-plating of plated parts;

[0...

Embodiment 3

[0051] After degreasing, alkaline etching and acid etching, the aluminum alloy is plated with nanometer rare earth oxides and carbon nanotubes on the aluminum substrate by secondary zinc dipping and pre-plating electroless nickel. Ni-based composite coating. The nanocomposite electroplating method is as follows:

[0052](1), prepare electroplating solution, its composition is: nickel sulfate 208g / L, nickel chloride 22g / L, sodium hypophosphite 16g / L, sodium sulfate 48g / L;

[0053] 16g / L nano rare earth oxides and 10g / L carbon nanotubes prepared by emulsion method;

[0054] Adjust the pH value of the plating solution with sulfuric acid and ammonia water, pH=2~4;

[0055] The nanometer rare earth oxide is nanometer yttrium oxide; the particle diameter of nanometer yttrium oxide is about 45 nanometers, and the particle diameter of carbon nanotubes is about 45 nanometers;

[0056] (2) Degreasing, activation and pre-plating of plated parts;

[0057] (3) The plating solution is h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com