Formula and preparation method of transparent water-based rubber parting agent

A release agent, water-based technology, applied in the direction of coating, etc., can solve the problems of dust pollution, manpower and material resources input, high production cost, low production efficiency, etc., without affecting the performance of subsequent processing technology, ensuring stability and environmental protection Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

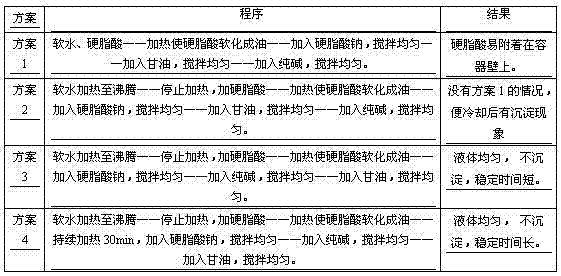

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 of the present invention: the formula of transparent water-based rubber release agent, calculated in parts by weight, it comprises 100 parts of deionized soft water, 0.8 part of sodium stearate, 1.5 parts of 800 type stearic acid, 1 part of glycerin and 1 part soda ash.

[0031] The preparation method of transparent water-based rubber release agent is to heat 100 parts of deionized deionized water to boiling under normal pressure, and then add 1.5 parts of 800 type stearic acid to the boiling deionized deionized water to obtain mixture A; heat mixture A into it The 800-type stearic acid softened into oily state, and then continued to heat for 30 minutes in a boiling state, and kept stirring to obtain a mixed solution B; add 0.8 sodium stearate to the mixed solution B, and stir evenly to obtain a mixed solution C; Add 1 part of soda ash to the mixture C and stir evenly, then add 1 part of glycerin, stir evenly, and place it at room temperature to obtain the ...

Embodiment 2

[0032] Embodiment 2 of the present invention: the formula of transparent water-based rubber release agent, calculated in parts by weight, it includes 100 parts of deionized soft water, 3 parts of sodium stearate, 4 parts of 800 type stearic acid, 3 parts of glycerin and 2 parts soda ash.

[0033] The preparation method of transparent water-based rubber release agent is to heat 100 parts of deionized deionized water to boiling under normal pressure, and then add 4 parts of 800 type stearic acid to the boiling deionized deionized water to obtain mixture A; heat mixture A to it The 800 type stearic acid is softened into oily state, then continuously heated in boiling state for 30 minutes, and kept stirring to obtain mixed solution B; add 3 sodium stearate to mixed solution B, and stir well to obtain mixed solution C; Add 2 parts of soda ash to the mixture C and stir evenly, then add 3 parts of glycerin, stir evenly, and place it at room temperature to obtain the finished product....

Embodiment 3

[0034] Embodiment 3 of the present invention: the formula of transparent water-based rubber release agent, calculated in parts by weight, it comprises 100 parts of deionized soft water, 0.3 part of sodium stearate, 1 part of 800 type stearic acid, 0.5 part of glycerin and 0.5 parts of soda ash.

[0035] The preparation method of transparent water-based rubber release agent is to heat 100 parts of deionized deionized water to boiling under normal pressure, and then add 1 part of 800 type stearic acid to the boiling deionized deionized water to obtain mixture A; heat mixture A into it The 800 type stearic acid softened into oily state, then continued to heat in boiling state for 30 minutes, and kept stirring to obtain mixed solution B; added 0.3 sodium stearate to mixed solution B, and stirred evenly to obtain mixed solution C; Add 0.5 parts of soda ash to the mixture C and stir evenly, then add 0.5 parts of glycerin, stir evenly, and place it at room temperature to obtain the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com