Ring-shaped electro-plastic self-piercing riveting system

An electroplastic, self-piercing riveting technology, applied in the field of mechanical engineering, can solve the requirements of reducing the rigidity of equipment punching riveting ability and rivet strength, reducing the plastic deformation resistance of riveted advanced high-strength steel, and radial cracks at the bottom of the joint. The effect of reducing riveting force, improving connection quality and easy mechanical interlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

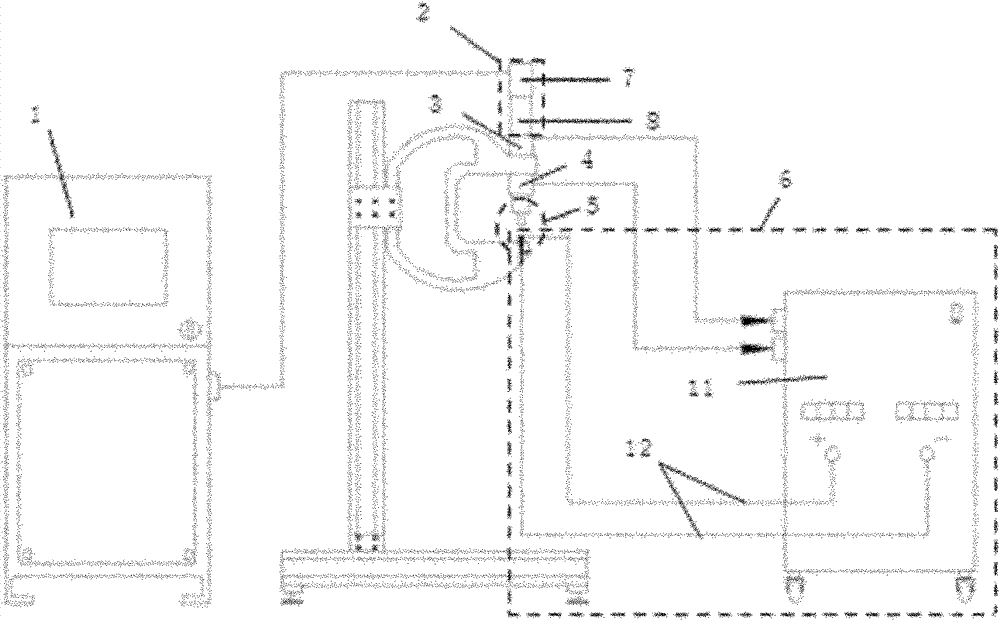

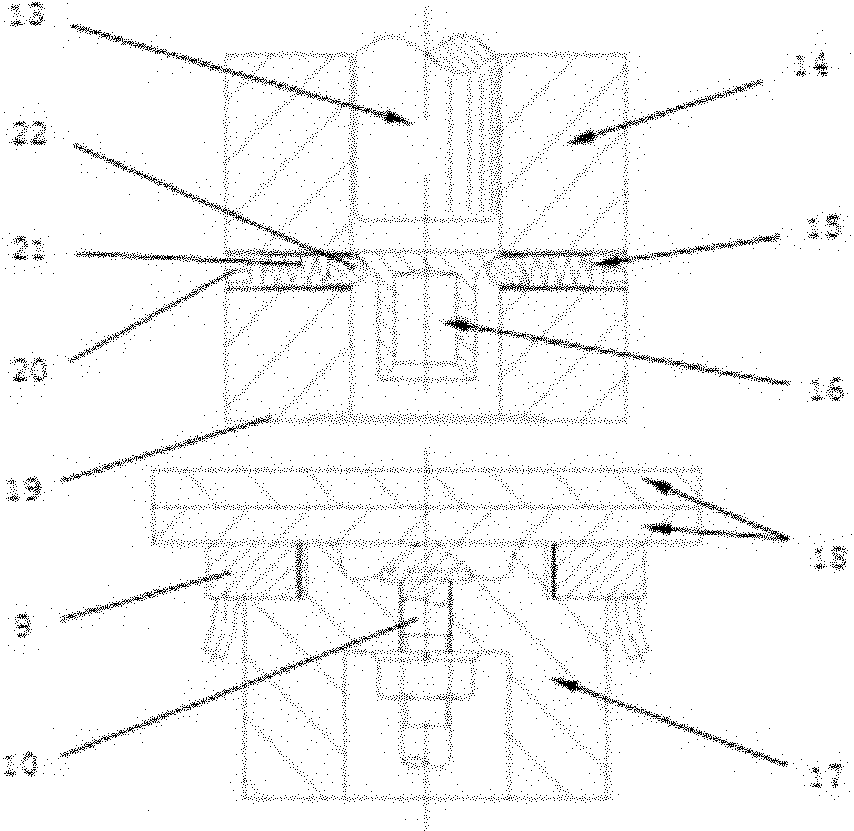

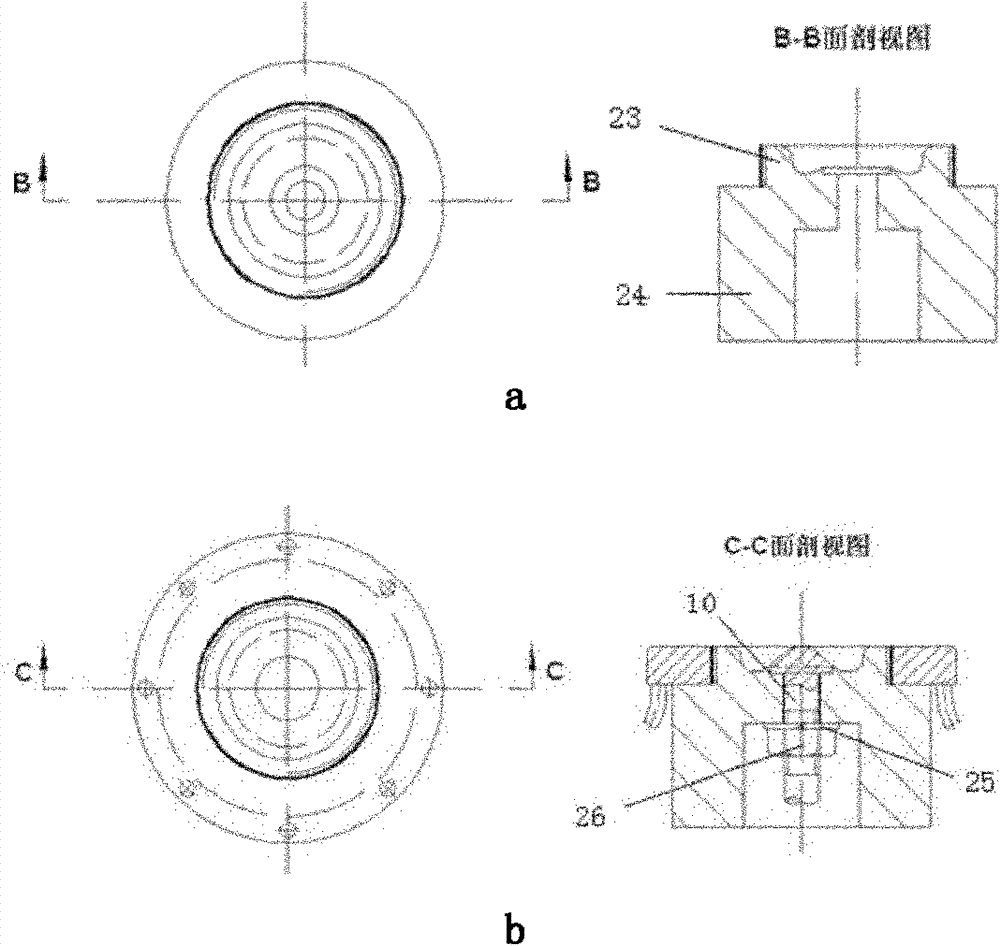

[0034] Such as figure 1 As shown, this embodiment includes: power and control cabinet 1, servo power system 2, displacement sensor 3, pressure sensor 4, riveting actuator 5 and ring electroplastic system 6, wherein: power and control cabinet 1 and servo power system 2-phase connection, the annular electroplastic system 6 is connected with the riveting actuator 5;

[0035] The servo power system 2 includes a servo motor 7 and a lead screw nut mechanism 8, the servo motor 7 is connected to the power and the control cabinet 1 to receive power and control cabinet control, and the output end of the servo motor 7 is connected to the lead screw and nut mechanism 8 to realize power delivery.

[0036] The displacement sensor 3 is connected in series under the screw nut mechanism 8 to convert the collected screw speed information into riveting speed information; the pressure sensor 4 is connected in series above the riveting actuator 5 to collect force feedback information from the mec...

Embodiment 2

[0056] The implementation conditions and process flow of this embodiment refer to Embodiment 1; the plates 18 to be connected in this embodiment are: aluminum alloy AA6061-T6+high-strength steel DP780, that is, the aluminum alloy is on the top, the high-strength steel is on the bottom, and the thickness of the plates matches: 2mm+1.4mm.

[0057] The semi-hollow rivet 16 in this embodiment adopts a traditional self-piercing riveting countersunk rivet with a head diameter of 7.8 mm, a leg outer diameter of 5.3 mm, and a rivet length of 7 mm. The material is boron-treated medium carbon steel.

[0058] Process parameters: the impact speed of the drive rod 13 is 120mm / min, the impact stroke is 7mm, and the current of the controllable DC power supply 11 is 600A.

[0059] Above-mentioned two embodiments have remarkable beneficial effect:

[0060] In the above embodiment, by applying current in the deformation direction of the material during the self-piercing riveting process, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com