Polyethylene glycol modifier of aspergillus flavus urate oxidase and preparation method thereof

A technology of uric acid oxidase and polyethylene glycol, applied in biochemical equipment and methods, methods based on microorganisms, microorganisms, etc., can solve problems such as long half-life, high cost of preparations, and increased risk of medication, and achieve production costs Low, low immunogenicity, long half-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited. Embodiment 1, preparation and activity determination of Aspergillus flavus uric acid oxidase

[0079] 1. Preparation of Aspergillus flavus uric acid oxidase

[0080] The preparation method of recombinant Aspergillus flavus urate oxidase comprises the following steps: (1), the acquisition of Aspergillus flavus urate oxidase gene; (2) construction of expression vector and transformation of Escherichia coli engineering bacteria: the synthetic Aspergillus flavus urate oxidase cDNA The fragment is inserted into the restriction site of the expression vector plasmid, and then directly transformed into E. coli host bacteria; (3), screening, culturing, and induced expression of positive clones: the positive clones are selected and cultured on the medium, and the target protein is induced to Expression; (4), separation and purification of fusion ...

Embodiment 2

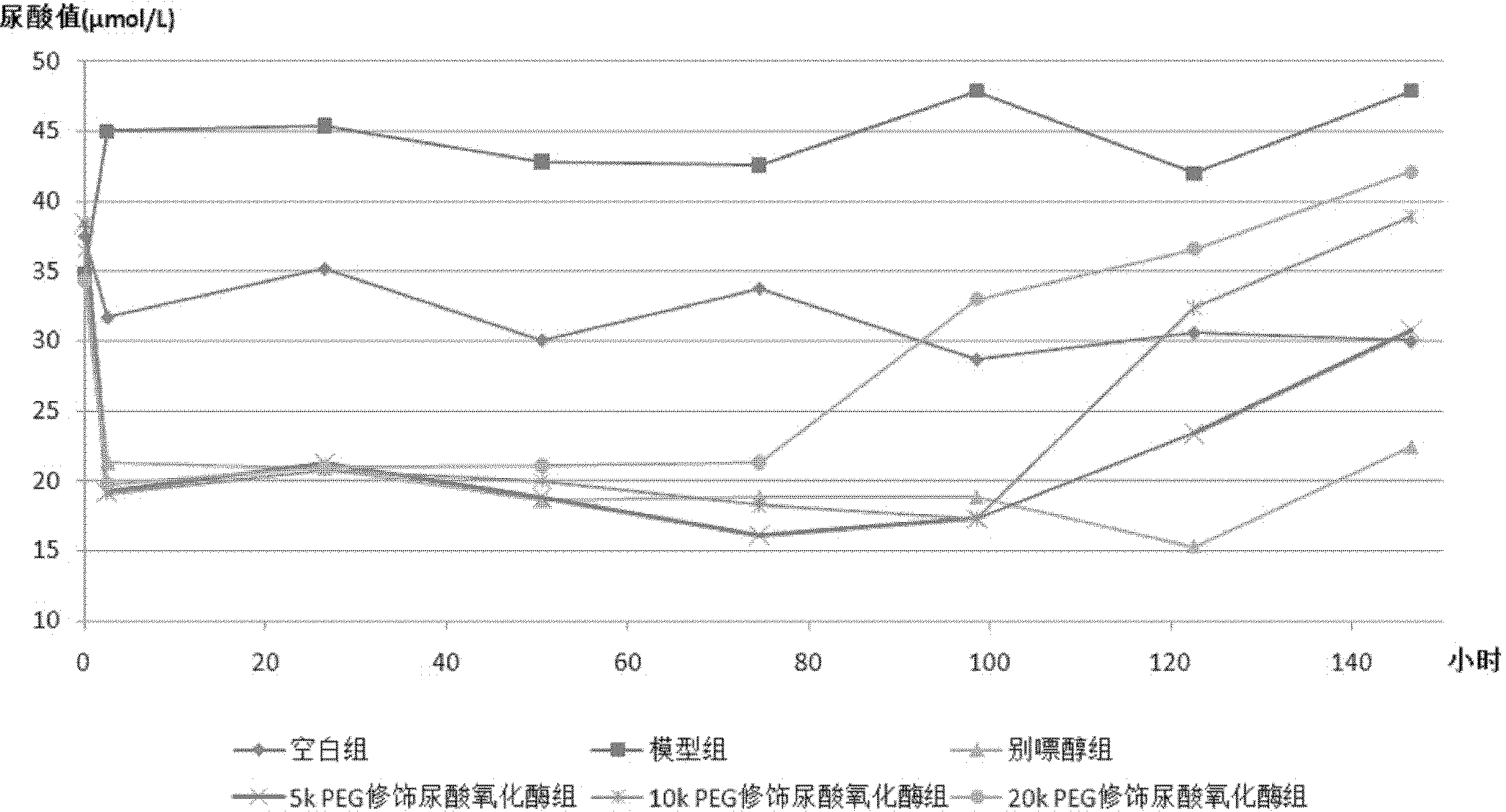

[0093] Embodiment two, different molecular weight PEG modified uric acid oxidase

[0094] 1. Preparation of modified products

[0095] Purified Escherichia coli expressing Aspergillus flavus uric acid oxidase has a purity greater than 95%, a concentration of 2.0mg / ml, exchanged the buffer with a G25 column, and prepared an equilibrium buffer of 0.1mol / L Na 2 PO 4 -20mmol / L NaCl, flow rate 10ml / min, load the sample after the column effluent reaches equilibrium, and collect the protein peak. Monomethoxy PEG propionate with different molecular weights was added to urate oxidase in a different buffer system at a mass ratio of 7:1, and the reaction was terminated after stirring at room temperature for 2 hours. Use a 50KD ultrafiltration membrane to ultrafilter the urate oxidase PEG reaction mixture against 20mmo / L PB, pH 8.0 buffer solution to remove free PEG, which is the urate oxidase PEG modified stock solution.

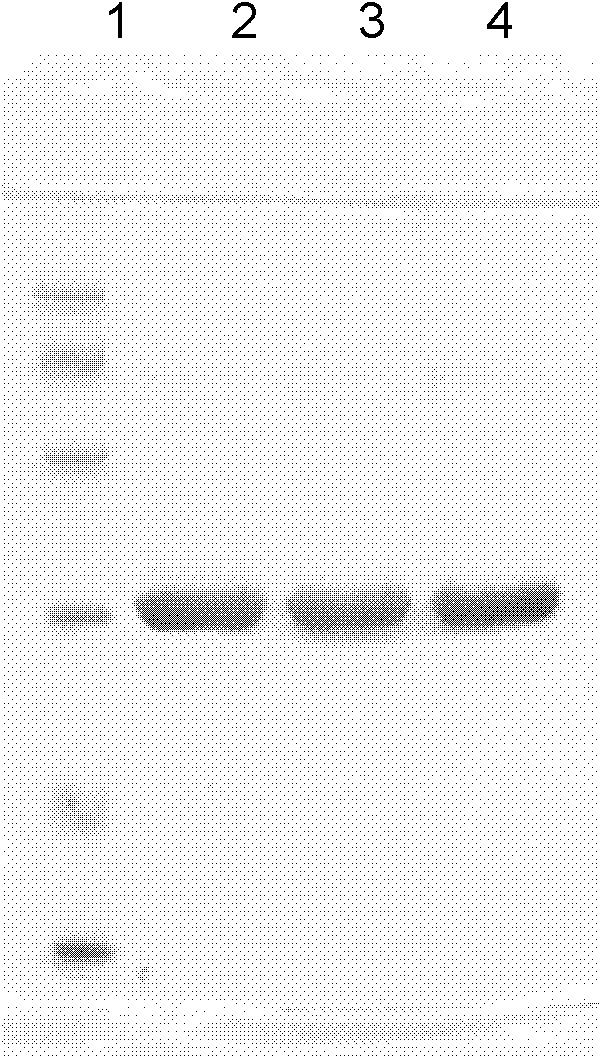

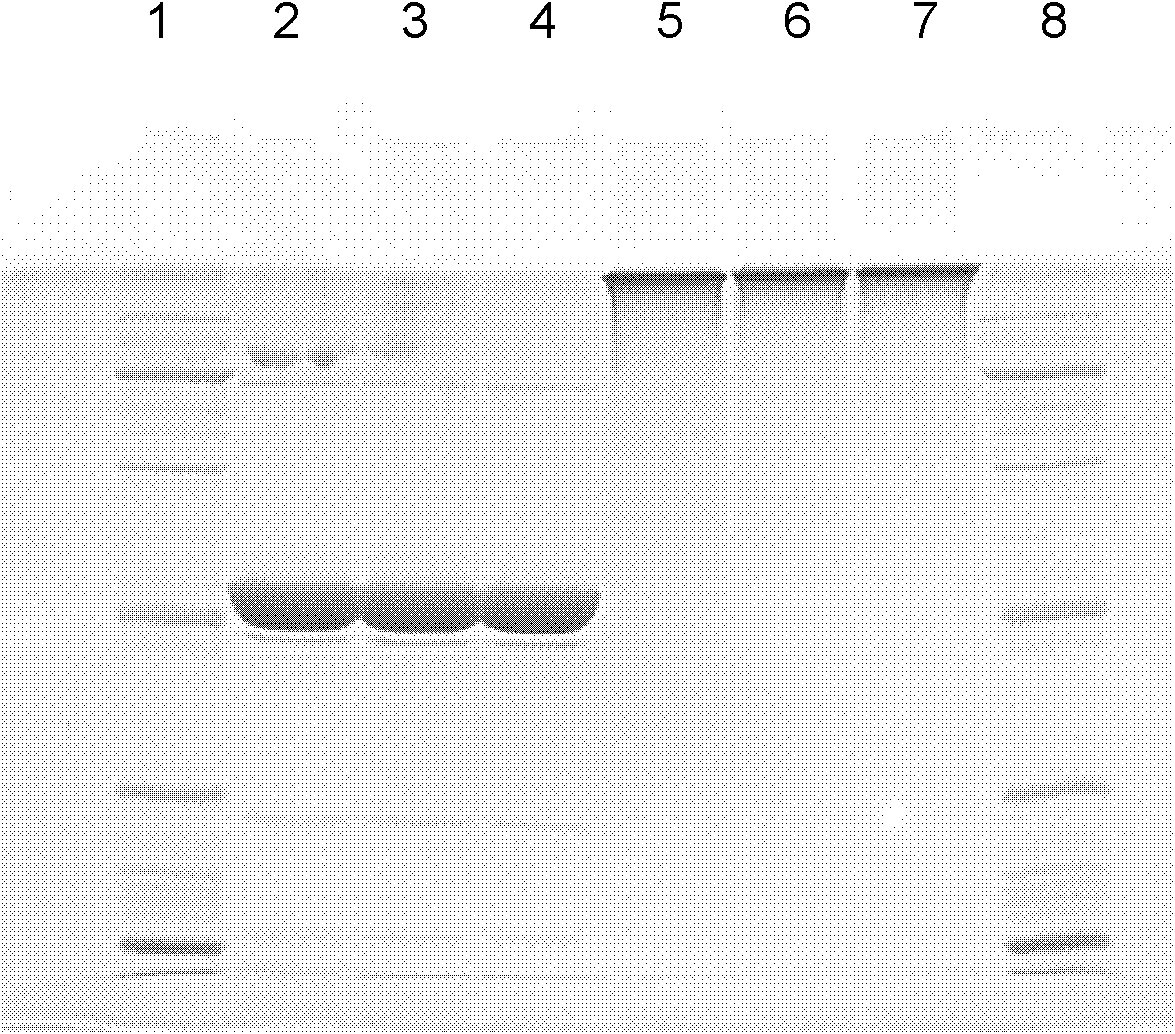

[0096] The modified product was analyzed by SDS-PAGE, and the ...

Embodiment 2

[0126] Samples 1-4 prepared in Example 2 and Samples 5-8 prepared in Comparative Example 1 were placed at 37° C. for one day to conduct an accelerated test for stability investigation. The activity retention of the samples is shown in Table 6.

[0127] Table 6. PEG urate oxidase stability accelerated test results

[0128] Numbering

[0129] The results of accelerated stability test showed that the enzyme activity of Aspergillus flavus uricase modified by single-point PEG lost quickly at 37°C, while the 5K molecular weight PEG-modified uricase of Aspergillus flavus with higher enzyme activity in multi-point modified samples could maintain better Stability, 92.7% of the activity can be maintained at 37°C for one day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com