Iron removal process for copper cobalt ore leach liquor

A technology of leaching solution, copper and cobalt, applied in the direction of improving process efficiency, can solve the problems such as failure and low utilization rate of hydrogen peroxide, and achieve the effects of convenient scrap treatment, low viscosity, and easy washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

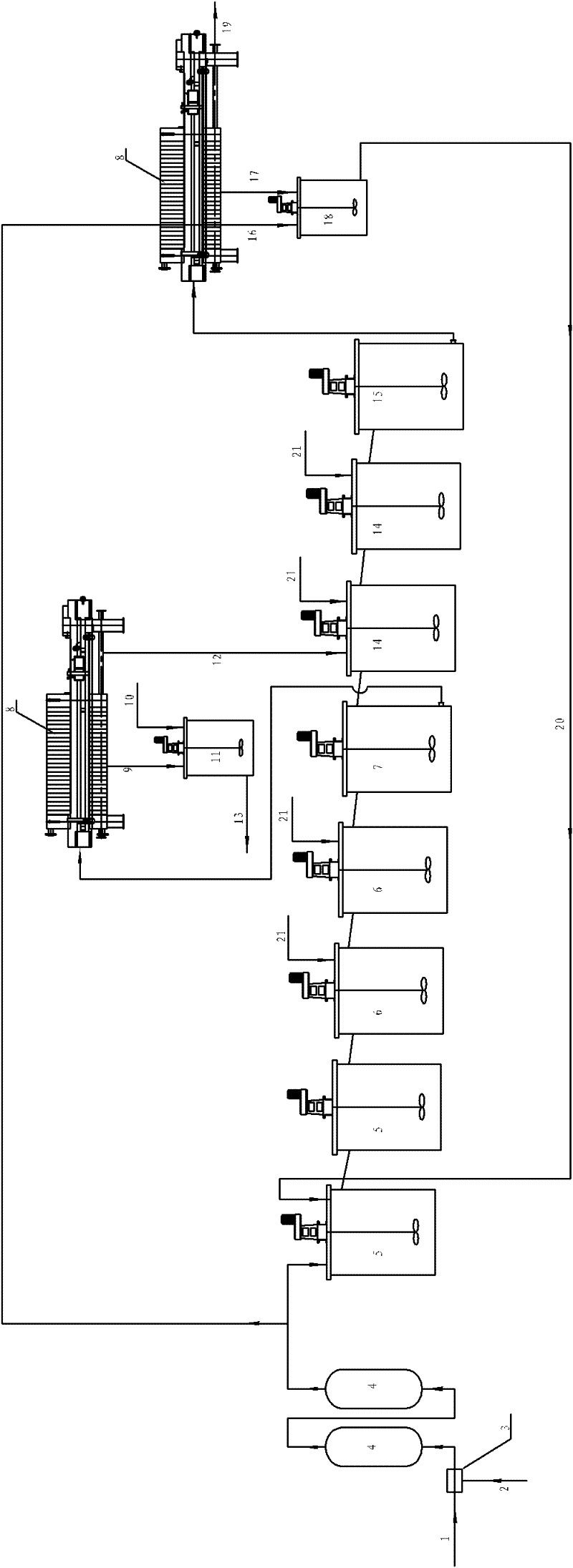

[0017] Such as figure 1 As shown, after the pre-oxidation liquid 1 and hydrogen peroxide 2 are mixed in the pipeline mixer 3, they enter the closed oxidation tank 4 to continue the oxidation reaction. The iron removal solution after oxidation is divided into two parts, one part (70-90%, that is, most of it) goes to the oxidation buffer tank 5, the existence of the oxidation buffer tank can prolong the oxidation time, if the oxidation in the oxidation tank is not complete, it can be oxidized Hydrogen peroxide is added to the buffer tank 5 to ensure that all the ferrous iron in the solution is oxidized to trivalent iron; The solution from the oxidation buffer tank 5 enters the iron removal tank 6 for iron removal by the goethite method. After the iron removal by the goethite method is completed, the slurry enters the iron removal buffer tank 7 by the goethite method, and the slurry passes through a filter press 8 After pressure filtration, the filter residue 9 and the slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com