Method and device for hot assembling large-diameter bearing

A large-diameter, heating device technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long construction period, increased cost of bearing thermal installation, high cost of waste liquid treatment, etc., to shorten the construction period and prevent partial Effects of overheating and short preparation times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The thermal loading method of the large-diameter bearing of the present invention comprises the following steps:

[0023] 1. Clean the bearing: clean the inside and outside of the bearing to be heated;

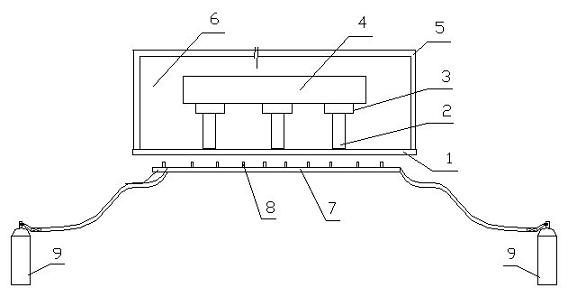

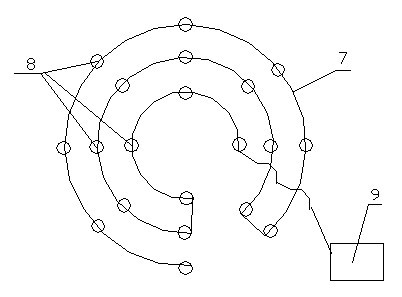

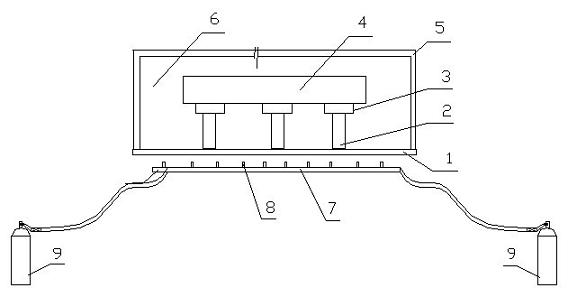

[0024] 2. Make the heating device: Determine the geometric size of the bottom plate of the heating device according to the diameter of the bearing to be heated; The coil is connected to the gas bottle, and the preparation work before heating is done; the gas bottle is a bottle body containing combustible gas, usually containing combustible gas such as coal gas and liquefied petroleum gas, as the energy source for heating.

[0025] 3. Calculate the bearing expansion according to the assembly technical requirements, and then determine the heating temperature of the bearing according to the expansion;

[0026] 4. Hang the bearing on the bottom plate of the heating device, place it on the support on the bottom plate, seal the bottom plate where the bearing is placed, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com