Athermal plasma purifying unit

A non-thermal plasma and plasma technology, applied in the field of plasma purification unit, can solve the problems of complex structure, increased volume and inconvenient use of air disinfection and purification unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

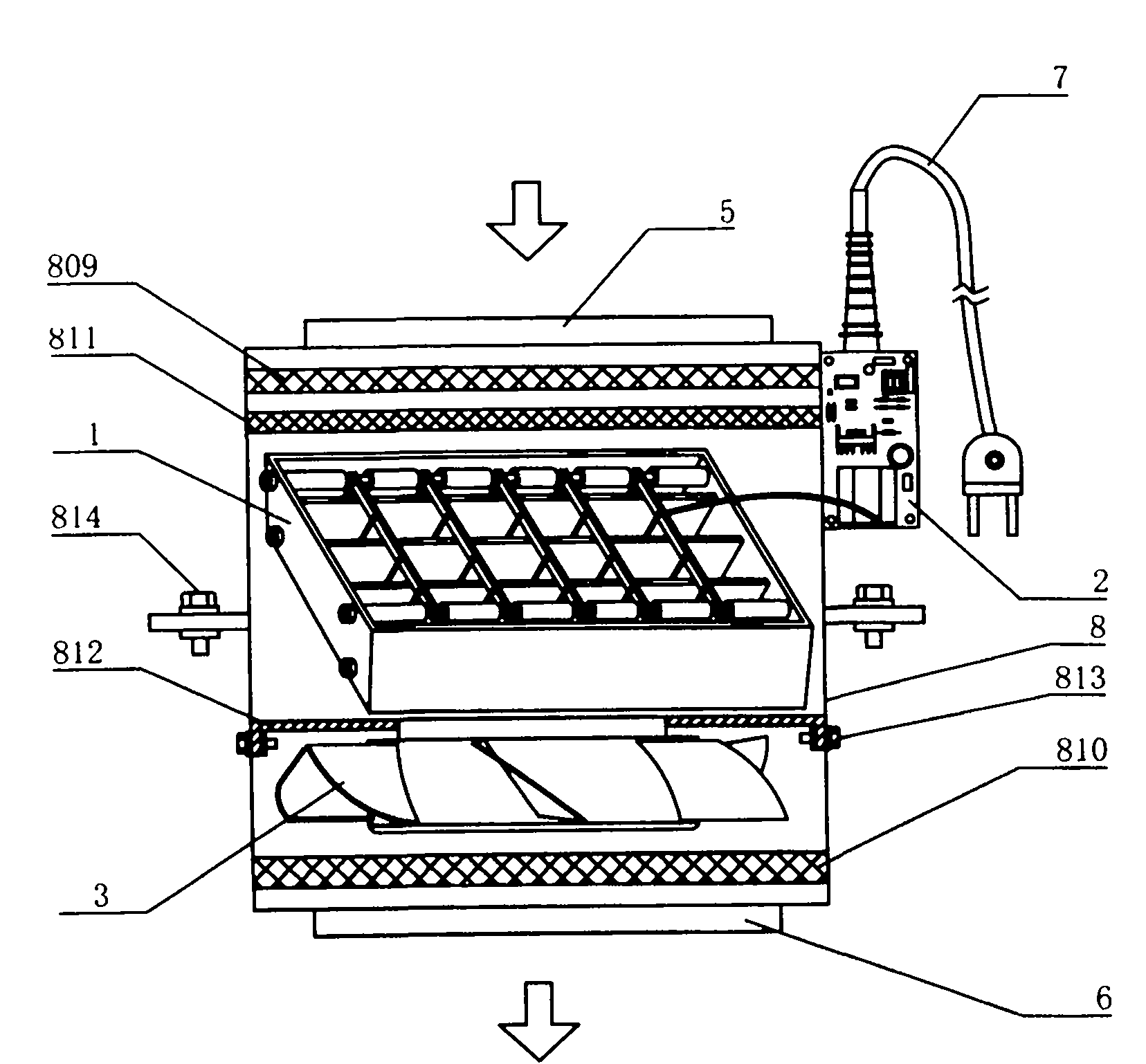

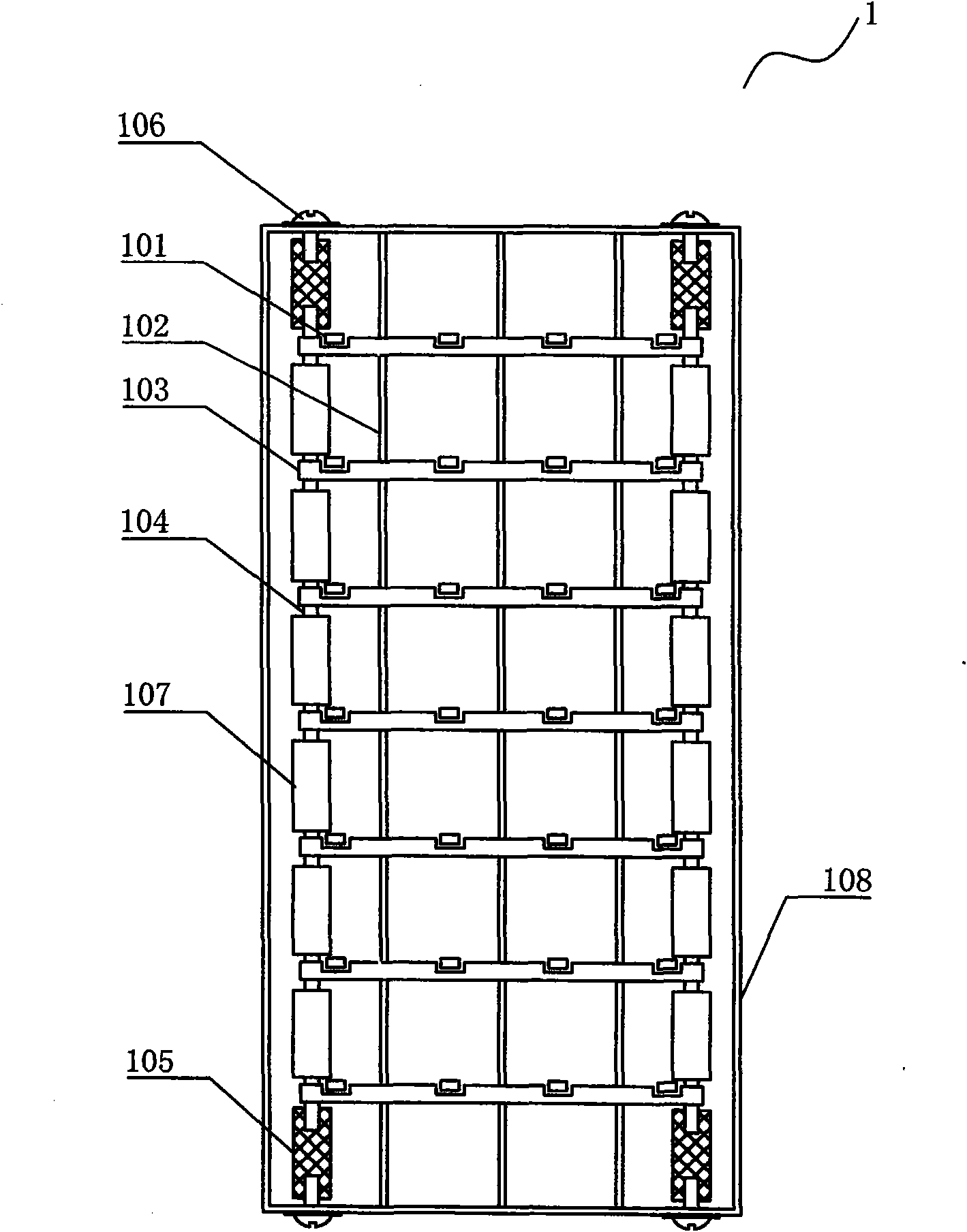

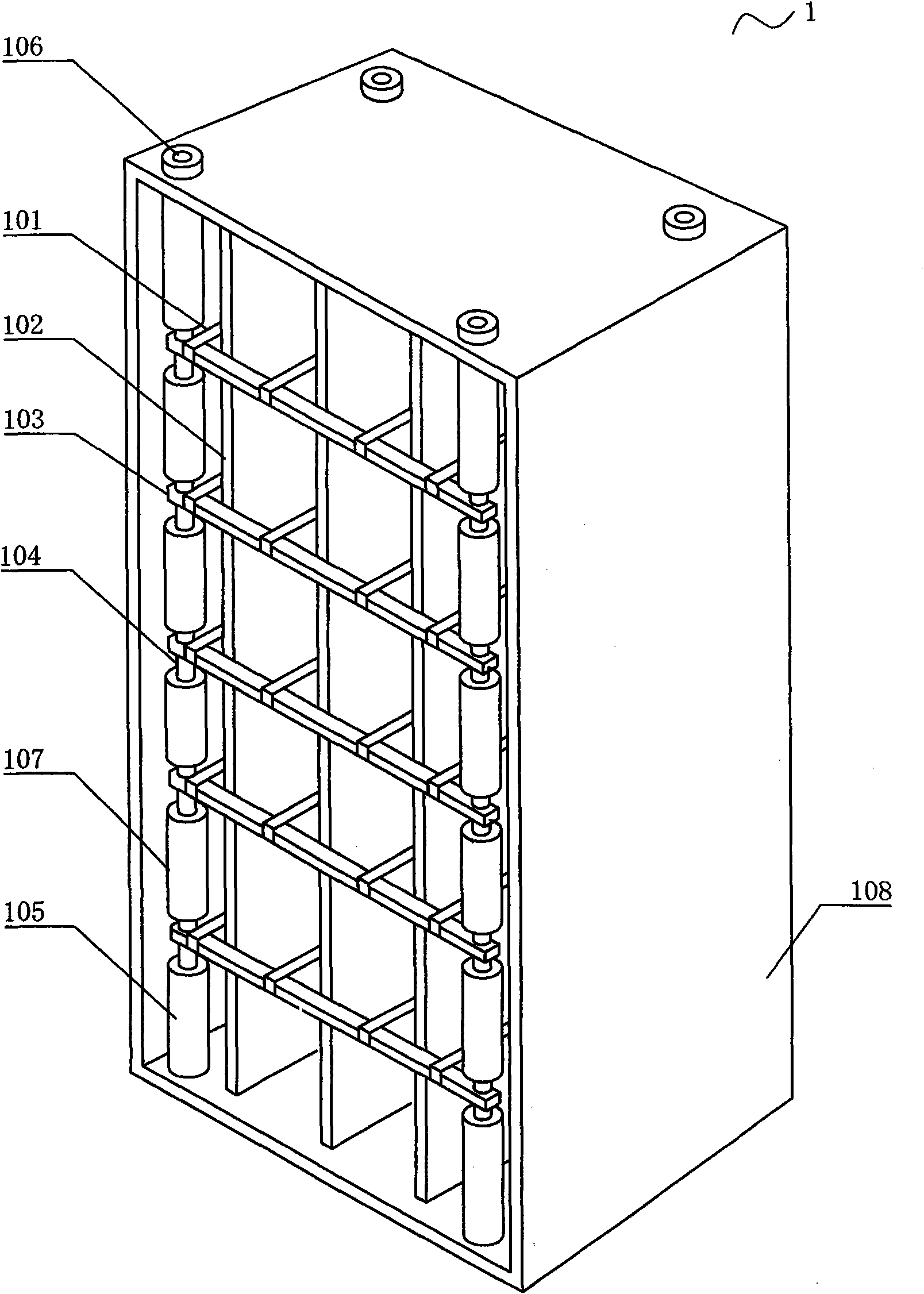

[0071] figure 1 is a schematic structural view of the non-thermal plasma purification unit of the present invention; figure 2 is a front sectional view of the plasma reactor of the present invention; image 3 It is the three-dimensional structure diagram of the plasma reactor of the present invention. The non-thermal plasma purification unit of the present invention comprises a plasma reactor 1, a pulse power supply 2, a fan assembly 3, an air inlet 5, an air outlet 6, a power supply connector 7 and a casing 8, the air inlet 5 is provided with an air filter 809, and the outlet The tuyere 6 is provided with an air filter 810, and the plasma reactor 1 is arranged in the air flow. The plasma reactor 1 is provided with positive electrodes 101 made of several nickel-chromium metal wires or nickel-chromium metal strips arranged in parallel at equal distances in the same plane, and the positive electrodes 101 are placed in the middle of two adjacent negative electrodes 102 . The ...

Embodiment 2

[0083] The anti-microdischarge conductive rail 103 provided by the non-thermal plasma purification unit of the present invention is made of aluminum rods or stainless steel bars, and the two ends of the positive electrodes 101 made of several nickel-chromium wires or nickel-chromium metal strips are fixed on the barriers. The corresponding position on the micro-discharge conductive rail 103 is positioned in the groove; the convex tip can also be used to replace the groove, which is acceptable for fixing the nickel-chromium metal wire, but the problem of skewing will occur when the nickel-chromium metal band is fixed. The inventor designed to use springs and stainless steel sheets to replace the corresponding grooves on the micro-discharge conductive rail 103 to fix the nickel-chromium metal wires and nickel-chromium metal strips. The elastic instability of the stainless steel sheet causes the nickel-chromium wire and the metal strip to sway even more. In severe cases, the posit...

Embodiment 3

[0085] The pulse transformer 206 provided by the non-thermal plasma purification unit of the present invention is provided with a multi-slot insulating bobbin 212, and the secondary coil 215 is divided into three sections, four sections or five sections and wound on the multi-slot insulating bobbin 212. connected in series in the groove. Generally speaking, the distributed capacitance of the windings wound in three sections is about one-ninth of the original, and the distributed capacitance of the windings wound in five sections is about one twenty-fifth of the original. The output end of the pulse transformer 206 is provided with a high voltage wire 213 connected to the anode of the plasma reactor 1 . The withstand voltage parameter of high-voltage fast recovery diode 217 is at least 12KV, and the recovery time is less than 80nS; Core 216 is electromagnetically coupled. The magnetic core 216 is an iron-based ultramicrocrystalline iron core, and the magnetic circuit is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com