A kind of auxiliary device for automatic yarn unwinding of winder

An auxiliary device and winding machine technology, applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., to achieve the effect of reducing wire breakage rate, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

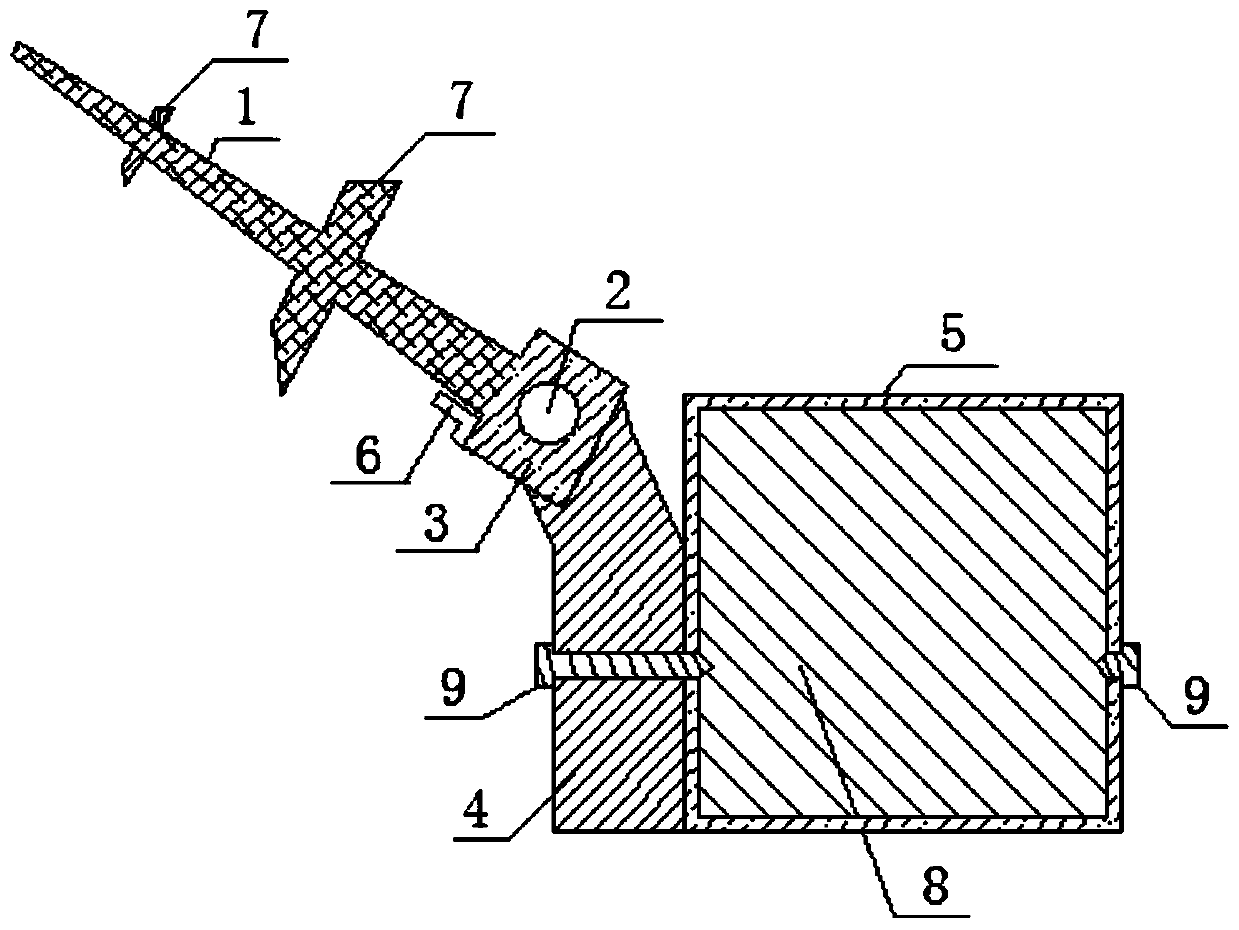

[0029] like figure 1 As shown, a schematic diagram of the structure of an automatic rewinding auxiliary device for a winding machine, including a spindle head 1, a spindle head shaft 2, a shaft sleeve 3, a spindle head seat 4 and a bracket 5, and the shaft sleeve 3 is fixed on the spindle head seat 4, the spindle head shaft 2 is set in the shaft sleeve 3 and can rotate freely, one end of the spindle head 1 extends into the shaft sleeve 3 and connects with the two ends of the spindle head shaft 2 and the end of the spindle head 1 away from the spindle head shaft 2 can swing up and down around the spindle head shaft 2, and the sleeve 3 is provided with a Angle limit bend 6, the spindle head 1 is provided with at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com