Purifier with metal band-plate structure reactor

A reactor and metal belt technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of ineffective electrostatic dust collection sterilization and decomposition of organic matter, and achieve good electromagnetic shielding performance and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

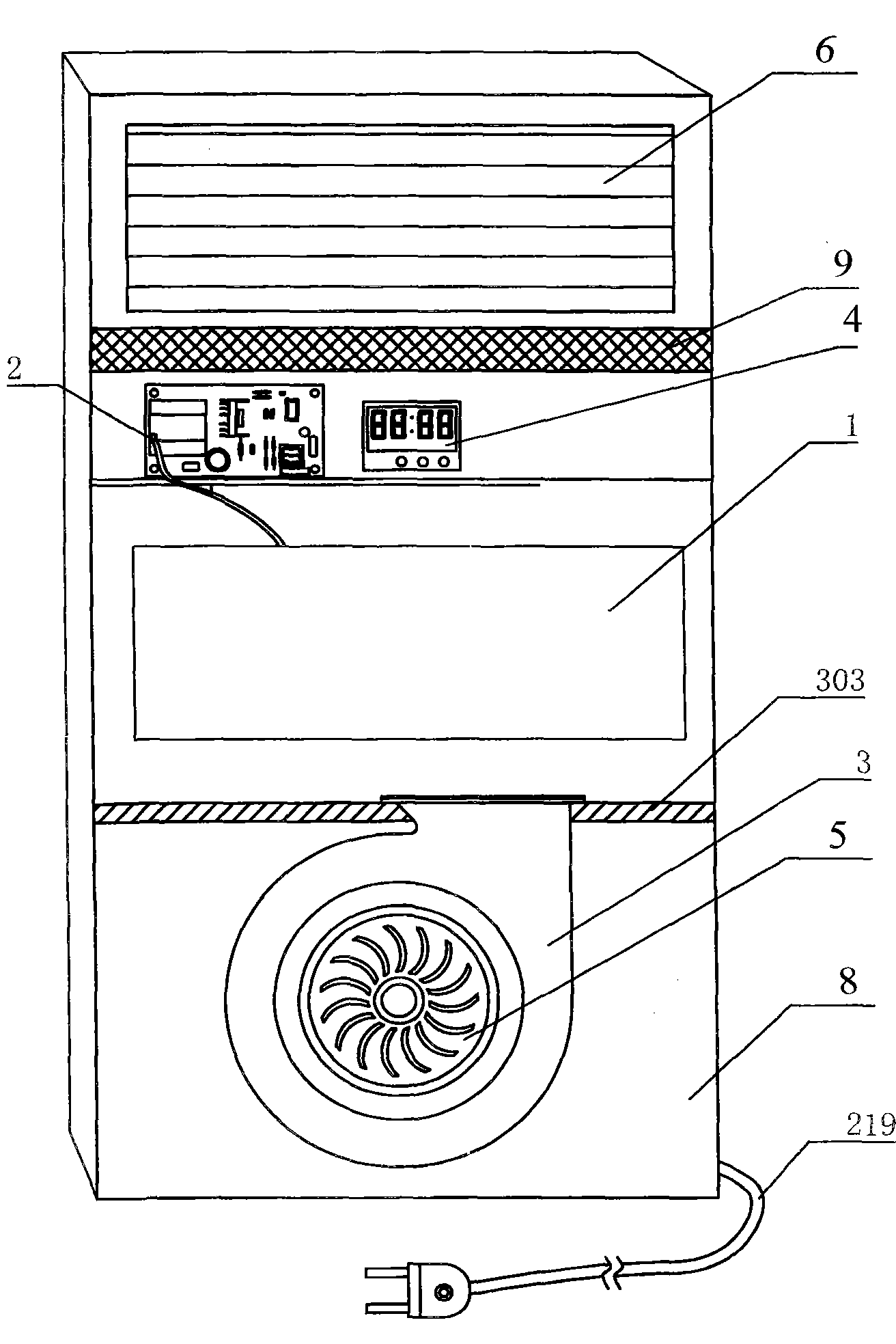

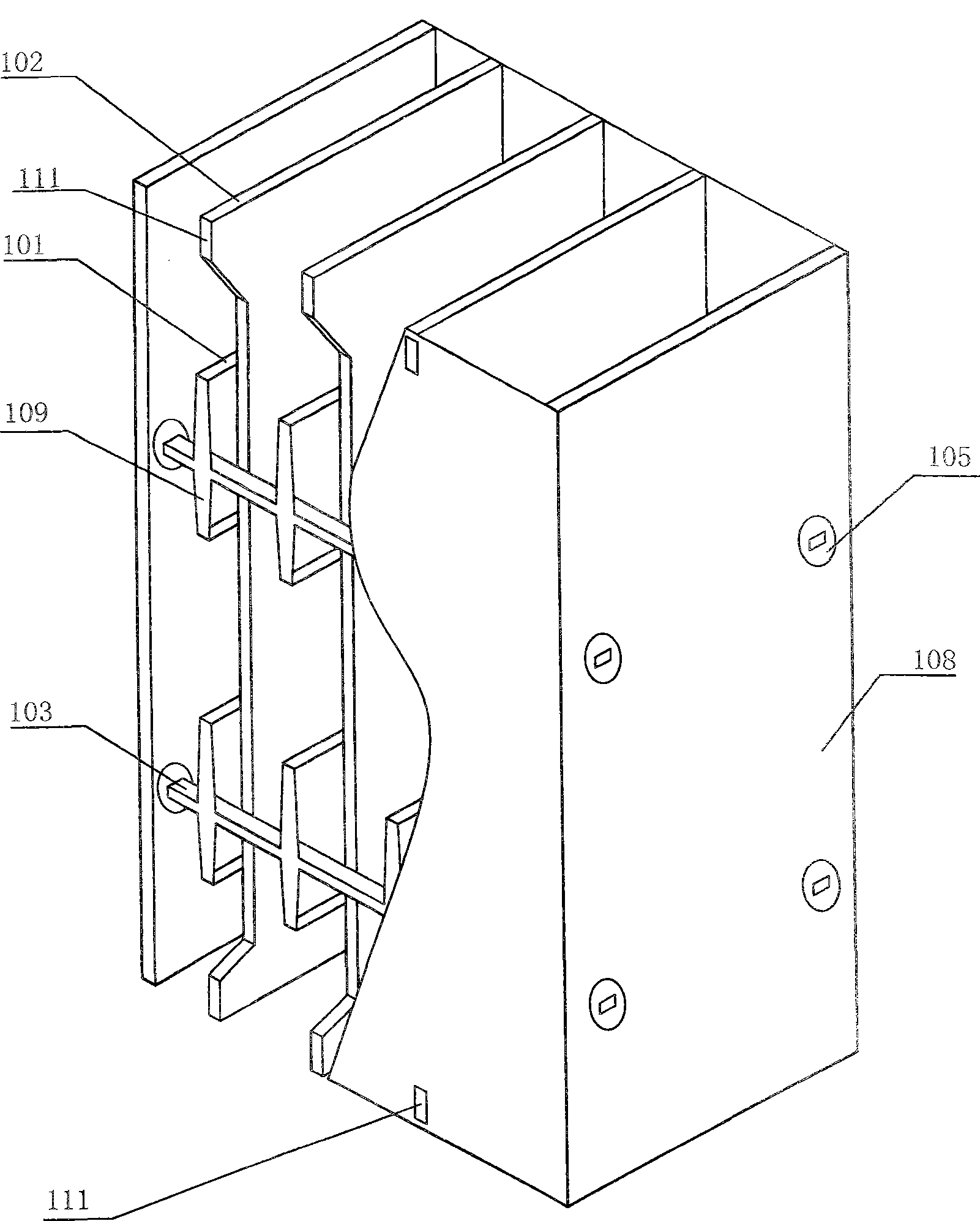

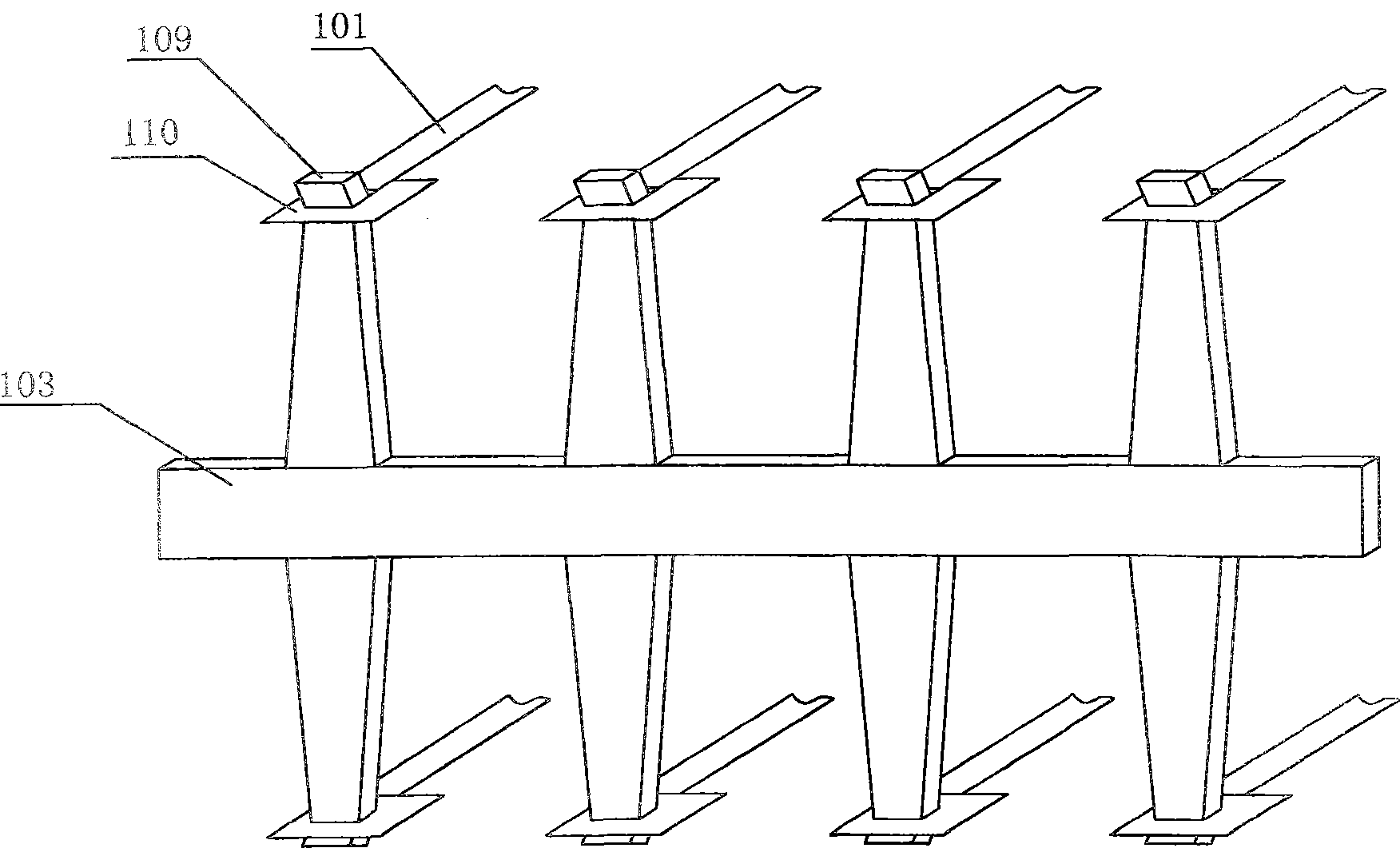

[0066] figure 1 It is a three-dimensional structure diagram of a purifier provided with a metal belt-plate structure reactor in the present invention; figure 2 It is a three-dimensional structure diagram of a plasma reactor half section of the present invention; image 3 It is a structural schematic diagram of the conductive rail for preventing micro-discharge of the present invention. The present invention is provided with the clarifier of metal strip-plate structure reactor, comprises plasma reactor 1, pulse power supply 2, fan assembly 3, controller 4, air inlet 5, air outlet 6 and shell 8, air inlet 5 The air filter 9 is provided with the air outlet 6, the plasma reactor 1 and the fan assembly 3 are arranged in the air flow, and the air outlet of the fan assembly 3 is airtightly installed with the windshield 303. The two output terminals of the controller 4 are electrically connected to the pulse power supply 2 and the power control terminal of the fan assembly 3 respec...

Embodiment 2

[0074] The protrusions 109 of the micro-discharge preventing conductive rail 103 described in the present invention are arranged as a group of two up and down symmetric ones, and each convex portion 109 of the micro-discharge conductive rail 103 is set as n groups, and the top of the convex portion 109 is set to the outside Elbow: The two ends of the positive electrode 101 are provided with a stainless steel connection frame 110, and the middle of the stainless steel connection frame 110 is punched into a square hole. The elbow at the top of the convex part 109 is inserted into the square hole of the stainless steel connection frame 110; the convex part 109 is a stainless steel elastic sheet with a thickness of 0.3-1mm. When assembling, the two ends of the stainless steel connection frame 110 and the positive electrode 101 are processed according to the designed length, and then the stainless steel connection frame 110 at both ends is inserted into the corresponding convex part...

Embodiment 3

[0076] The negative electrode 102 according to the present invention is provided with a protruding negative electrode fixing pin 111 at the upper and lower ends of the reactor shell 108, and the corresponding part of the reactor shell 108 is provided with grooves for docking and fastening. The thickness of the negative electrode aluminum plate is set at 1-2.0 mm, the surface is oxidized, the working life is long, and the appearance is bright. Alternatively, the thickness of the stainless steel plate used as the negative electrode 102 is 0.5-1.5 mm. Welding technology is used in the implementation, and there is warping phenomenon. There will be assembly errors when bending the negative electrode 102 and twisting the nails, and the process is not as good as this preferred embodiment. Both sides of the negative electrode 102 are coated with nano-scale TiO 2 It is an anatase catalyst with a band gap energy of 3.2eV.

[0077] The positive electrode 101 of the present invention i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com