Process for producing thick plate of plastic die steel

A technology of plastic mold steel and production process, which is applied in the field of thick plate preparation technology of age-hardening steel, can solve the problems of low plate thickness specification, imperfect technology and high cost, and achieves no shrinkage cavity, fast pouring speed and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

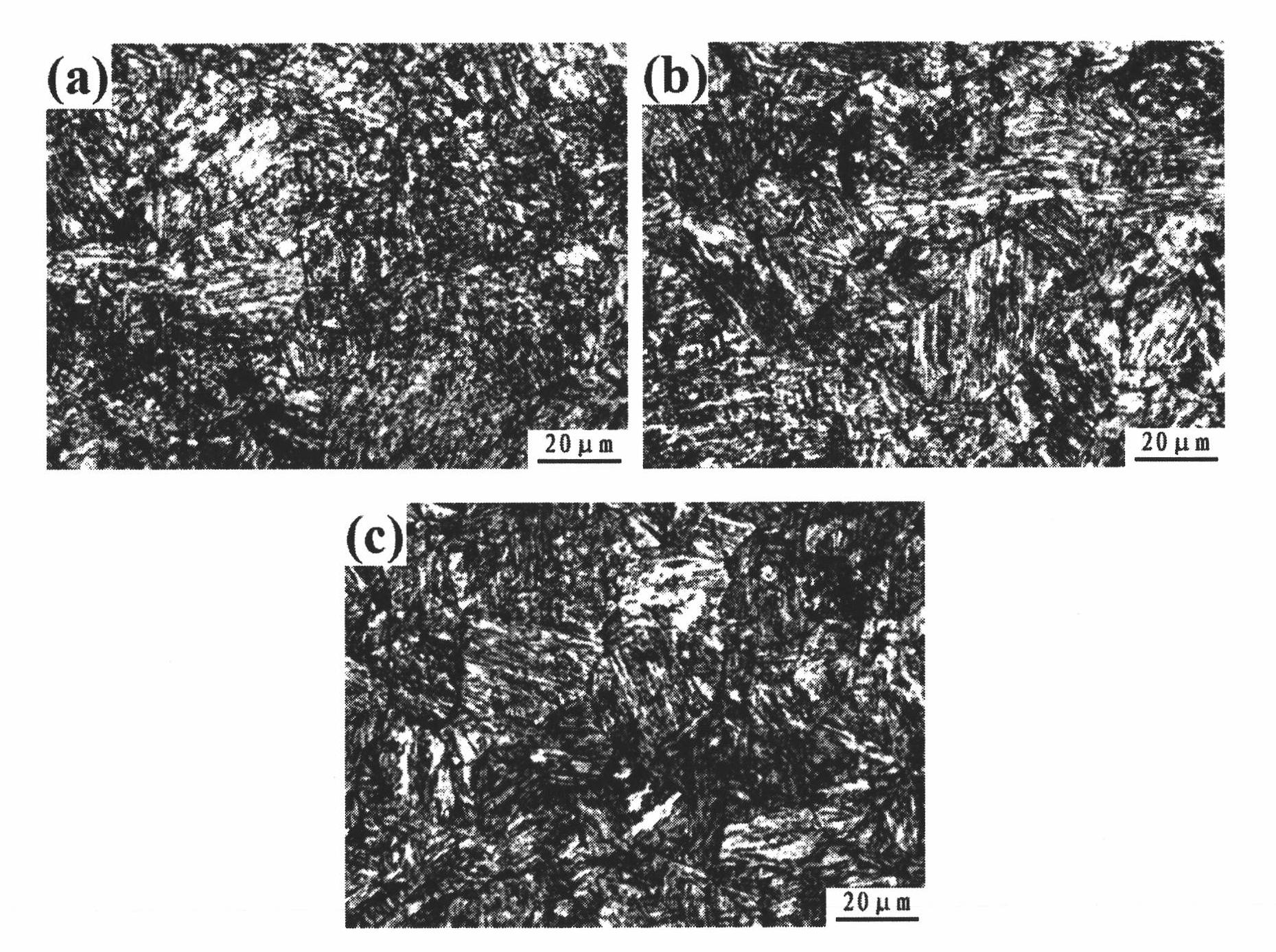

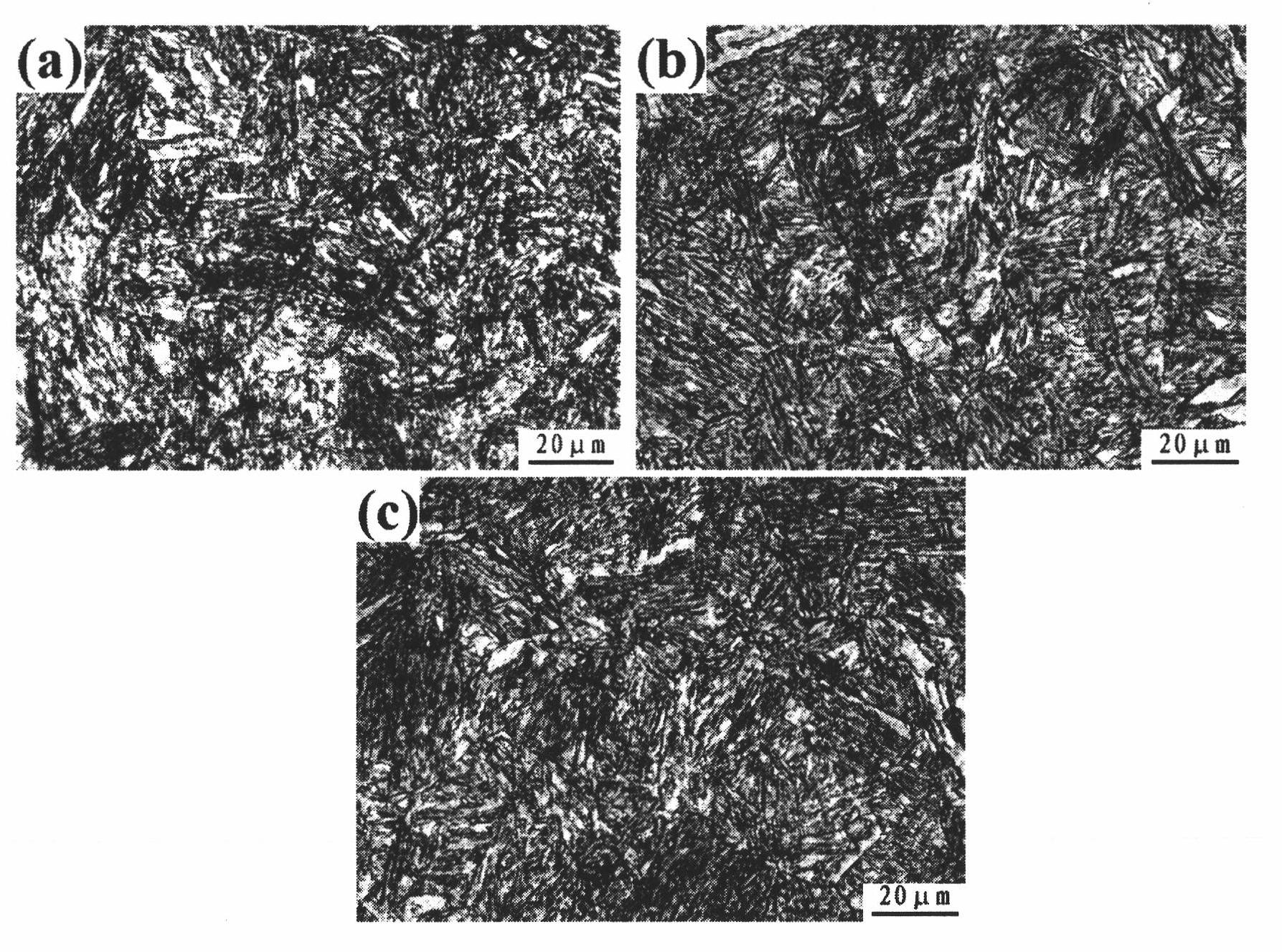

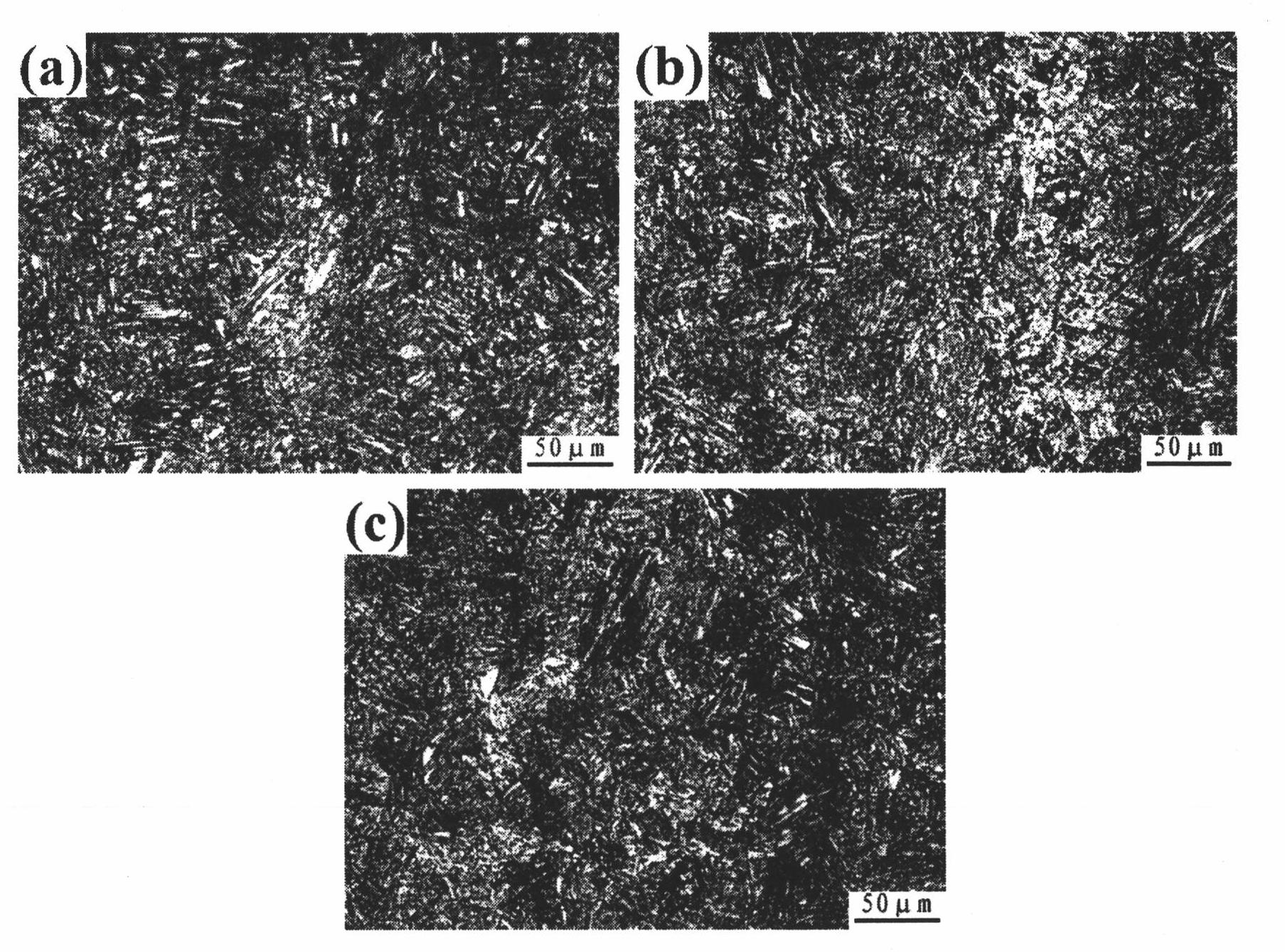

Image

Examples

Embodiment Construction

[0029] A thick plate production process of plastic mold steel, age-hardening plastic mold steel P80A chemical composition weight percentage: carbon 0.11-0.14%, manganese: 1.70-1.85%, nickel 2.85-3.15%, molybdenum: 0.25-0.35%, aluminum: 0.80~1.00%, silicon: 0.17~0.27%, copper 0.85-1.00, phosphorus≤0.015, sulfur≤0.012. The production process adopts a split-type water-cooled die-casting machine for pouring, through a reasonable heating system and rolling process, and through normalizing and tempering after rolling to obtain plastic mold steel thick plates. The specific steps are as follows:

[0030] A billet with a thickness of 400mm, a width of 2.2m and a length of 3.5m was poured using a split-type water-cooled die casting machine. Under the condition of water circulation, it is forced to cool and solidified into a billet. The billet has no defects such as internal cracks, external cracks and belly. The billet is compact and has good internal and external quality. When pouring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com