Hot metal pretreatment long-service-life spray gun

A technology for molten iron pretreatment and longevity, which is applied in the field of molten iron pretreatment and longevity spray guns, can solve the problems of unusable, short service life and high cost, and achieves the effects of not easy ablation, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

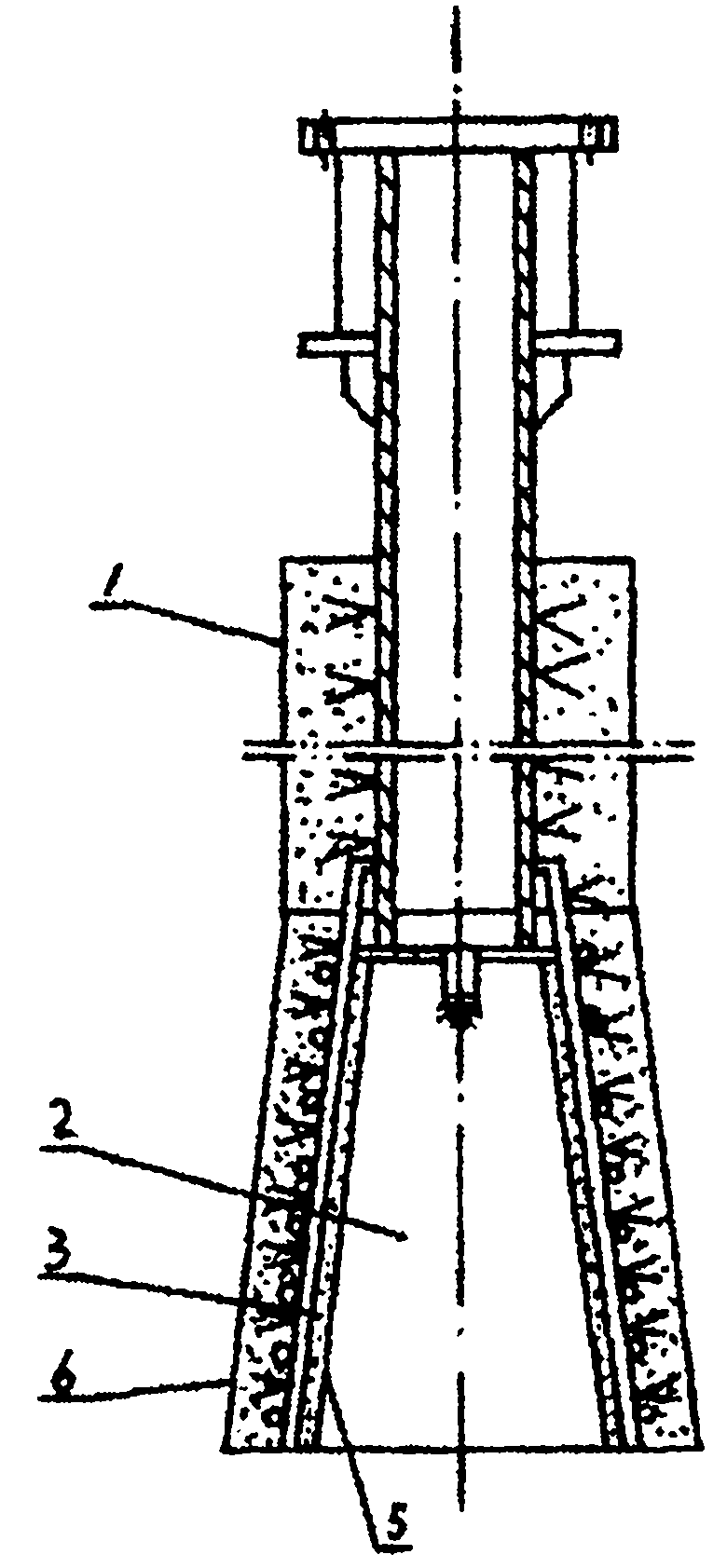

[0009] see figure 1 , The hot metal pretreatment longevity spray gun includes a gun body 1 and a gasification chamber 2 in the shape of a bell mouth at its lower part. The gasification chamber 2 is composed of a stainless steel framework 3 and inner and outer surfaces 5, 6 formed by cast refractory materials.

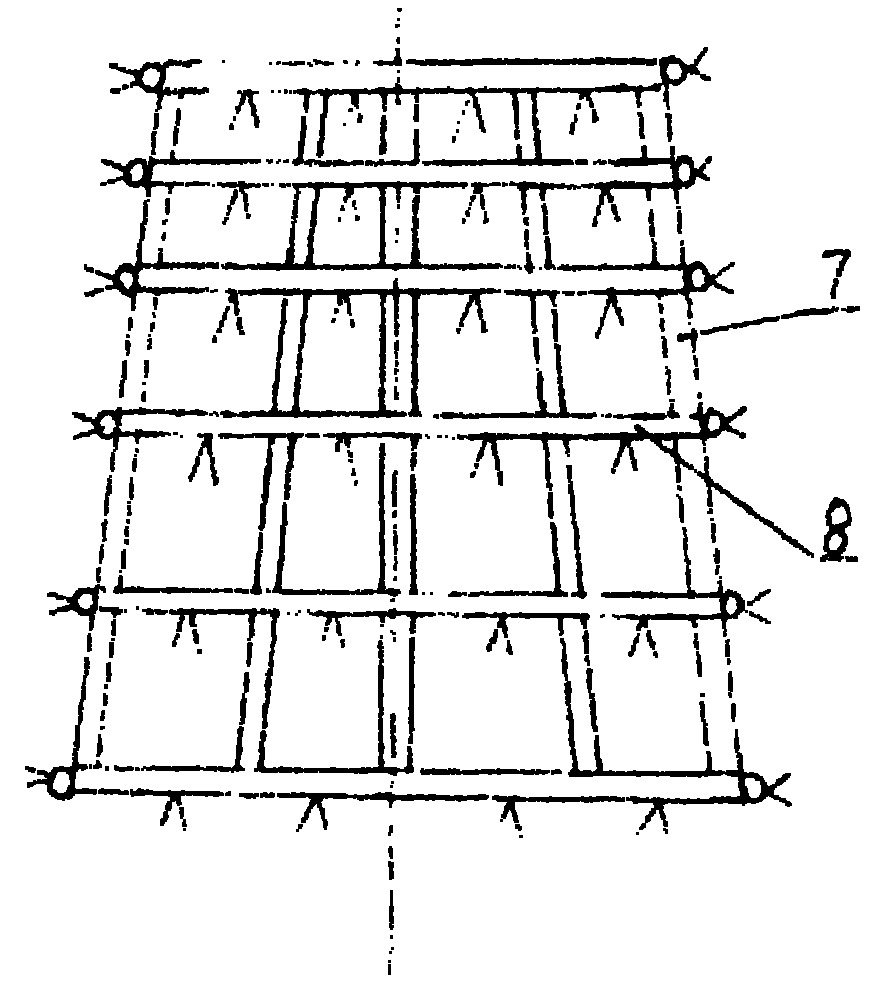

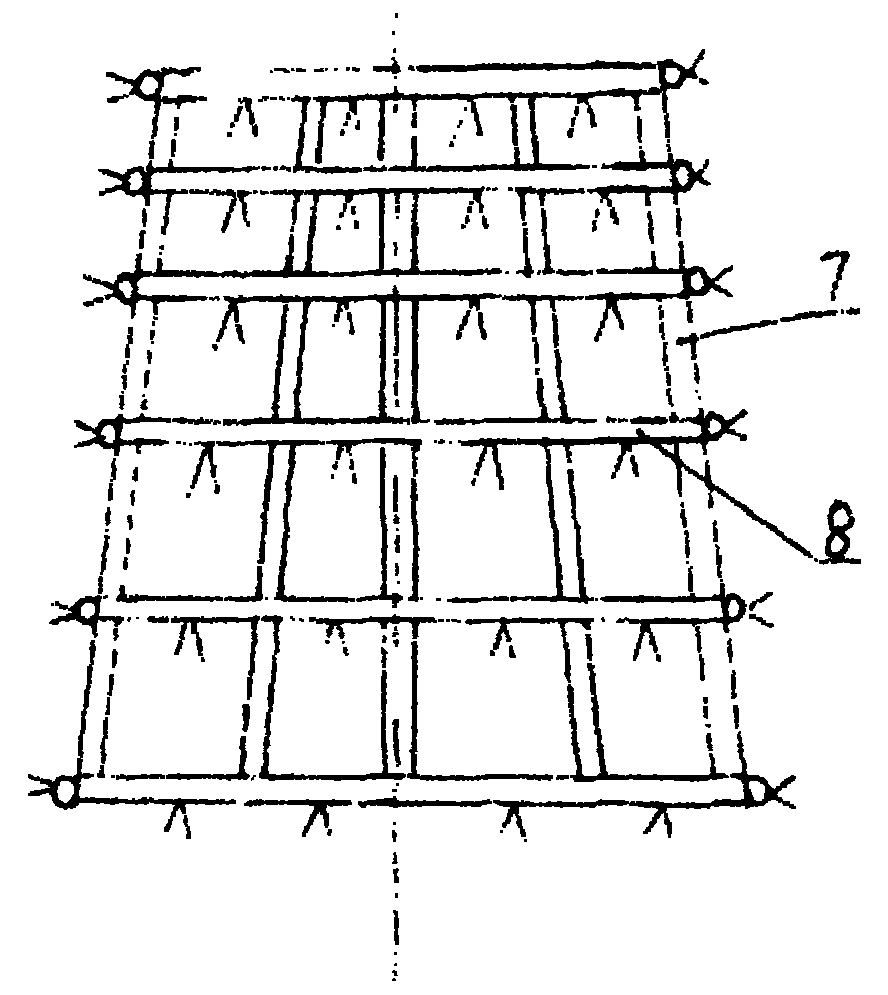

[0010] see figure 2 , The stainless steel frame 3 is surrounded by vertical and horizontal stainless steel bars 7 and 8 to form a trumpet shape at intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com