Catalysis upgrading method for cracking ethylene by-product carbon-9

A technology for the catalytic extraction of carbon nine and ethylene by-product, which is applied in the petroleum industry, hydroprocessing process, and hydrocarbon oil treatment, can solve problems such as instability, dark color, and strong odor, and achieve increased life, simple process, and suppression Effects of Aggregation and Coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

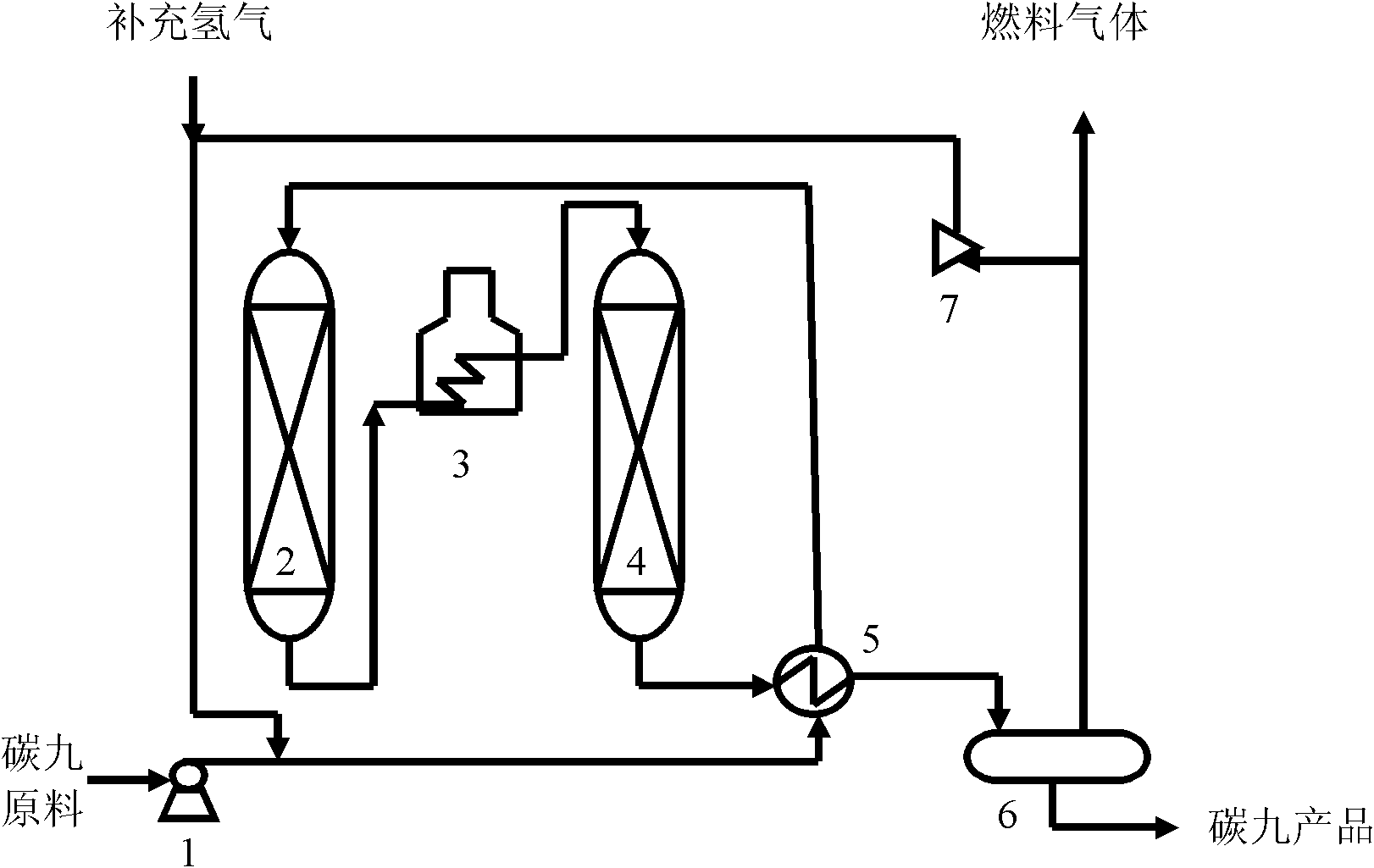

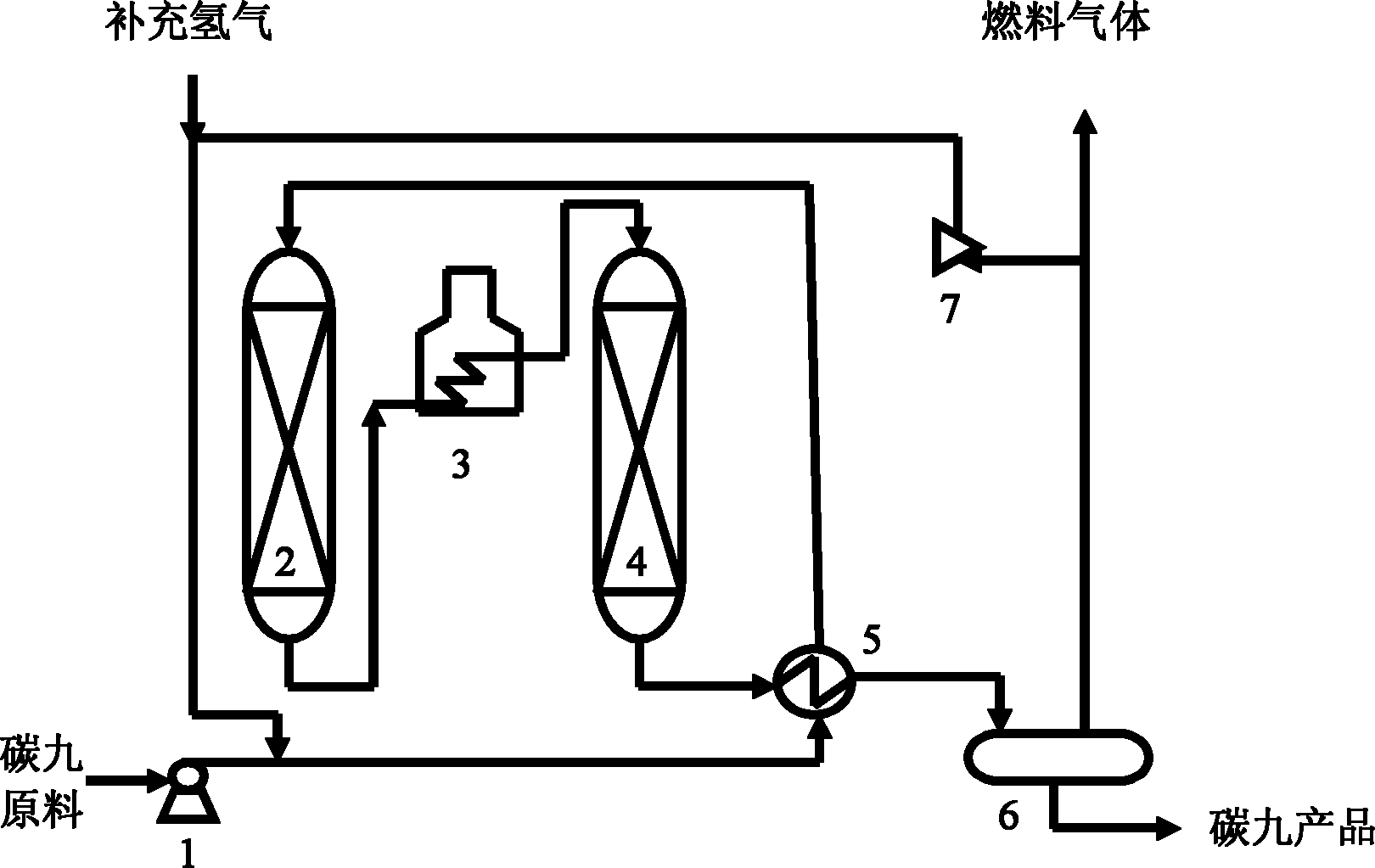

Method used

Image

Examples

Embodiment 1

[0020] The first-stage hydrogenation catalyst adopts a supported nickel-based catalyst. The carrier adopts SiO 2 -Al 2 o 3 , the specific surface area is 200-400m 2 / g, the pore volume is 0.5-2.0cm 3 / g, the most probable pore size distribution is 2-4nm and 10-15nm. The metal nickel precursor is nickel nitrate, nickel acetate or nickel acetylacetonate. The supported nickel-based catalyst is prepared through the steps of impregnation-drying-calcination-reduction and the like by adopting an equal-volume impregnation method, and the nickel content is between 5-30%, preferably between 10-20%.

[0021] The second-stage hydrogenation catalyst uses a supported cobalt-molybdenum sulfide catalyst. The carrier adopts SiO 2 -Al 2 o 3 , the specific surface area is 200-400m 2 / g, the pore volume is 0.5-2.0cm 3 / g, the most probable pore size distribution is 2-4nm and 10-15nm. Cobalt molybdenum sulfide precursor adopts cobalt nitrate or cobalt acetate or cobalt acetylacetonate ...

Embodiment 2

[0023] The one-stage hydrogenation catalyst adopts supported palladium-based catalyst. The carrier adopts SiO 2 -Al 2 o 3 , the specific surface area is 200-400m 2 / g, the pore volume is 0.5-2.0cm 3 / g, the most probable pore size distribution is 2-4nm and 10-15nm. The metal palladium precursor is palladium nitrate, palladium chloride, palladium acetate or palladium acetylacetonate. The supported palladium-based catalyst is prepared by the steps of impregnation-drying-roasting-reduction and the like by adopting an equal-volume impregnation method, and the nickel content is between 0.1-5%, preferably between 0.5-3%.

[0024] The second-stage hydrogenation catalyst uses a supported nickel-molybdenum sulfide catalyst. The carrier adopts SiO 2 -Al 2 o 3 , the specific surface area is 200-400m 2 / g, the pore volume is 0.5-2.0cm 3 / g, the most probable pore size distribution is 2-4nm and 10-15nm. The precursor of nickel molybdenum sulfide is nickel nitrate or nickel aceta...

Embodiment 3

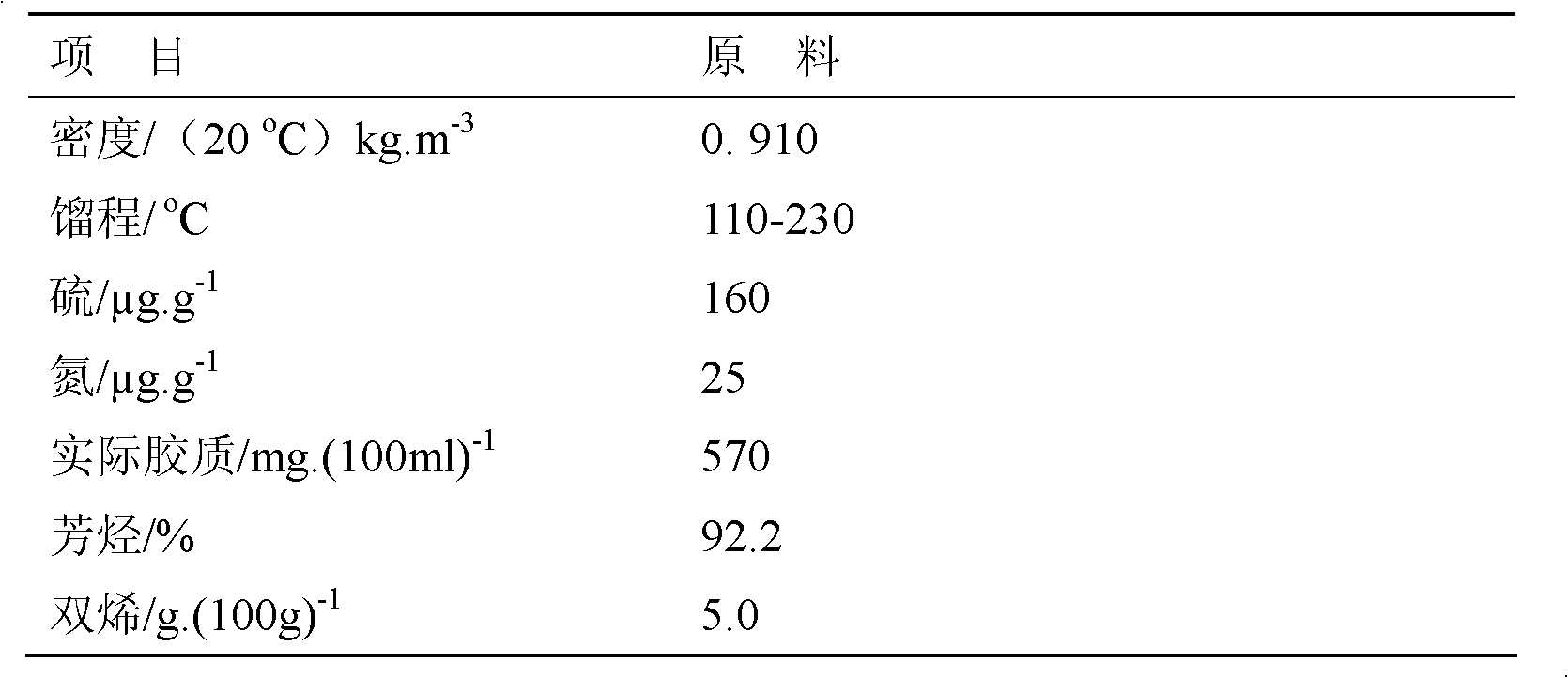

[0026] The properties of a by-product C9 fraction from cracking ethylene are shown in Table 1. It can be seen from the table that the by-product of cracking ethylene, the C9 fraction, has a higher density, a higher distillation range than gasoline, a high content of sulfur and nitrogen, and contains a large amount of colloid and diene components. Therefore, the production of high-octane gasoline components or high-grade aromatic solvent oils by cracking ethylene by-product carbon nine fractions requires the removal of sulfur, nitrogen, colloids and diolefins, etc., while reducing the density and distillation range.

[0027] Table 1 Properties of cracked ethylene by-product carbon nine cuts

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com