Method and device for removing impurities from trichlorosilane mixed gas

A technology of trichlorosilane and a treatment method, applied in the directions of halogenated silicon compounds, silicon, halogenated silanes, etc., can solve the problems of high energy consumption, insufficient comprehensive utilization of the cooling capacity at the top of the tower and the heat in the tower kettle, and reduce the burden. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

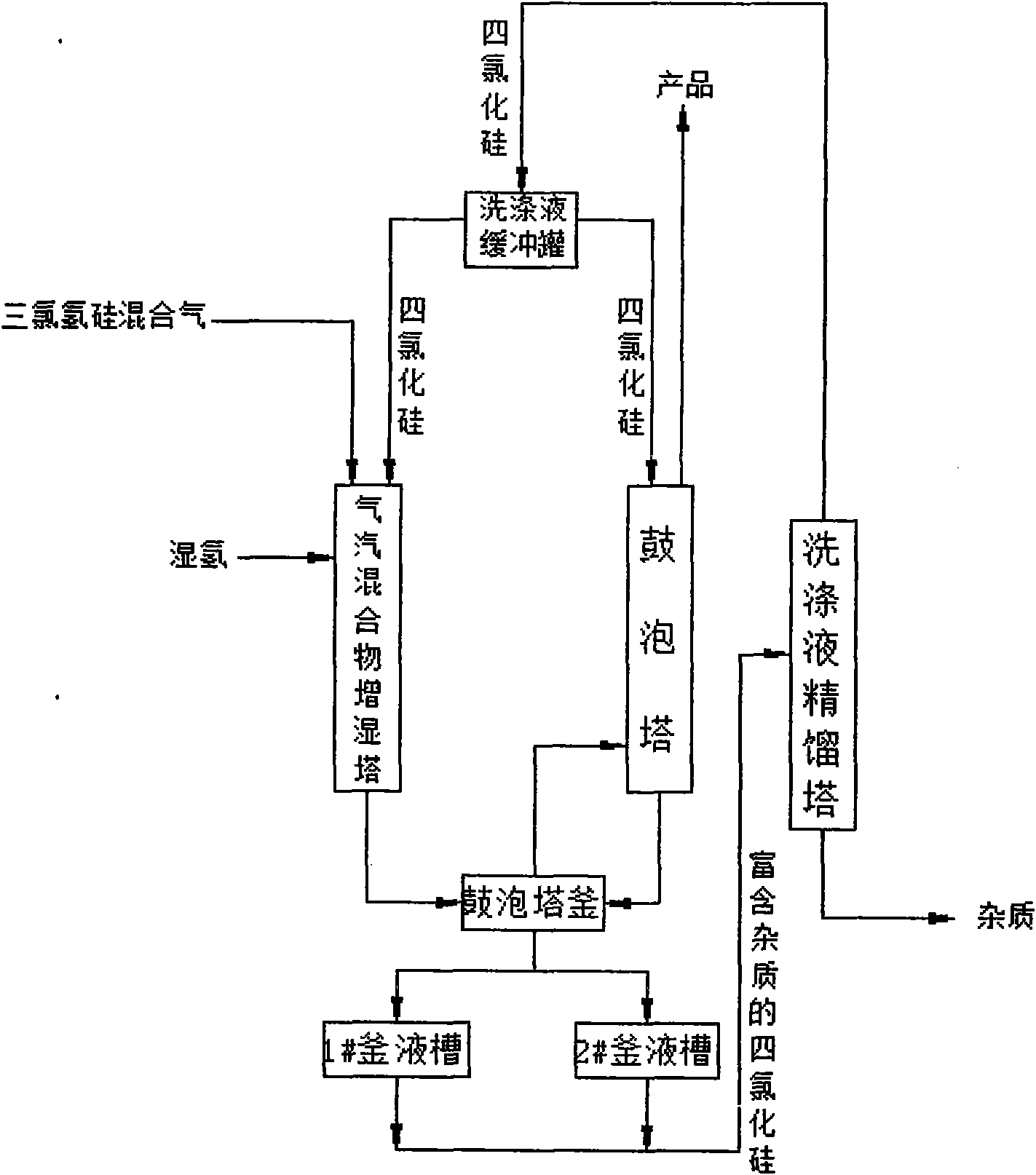

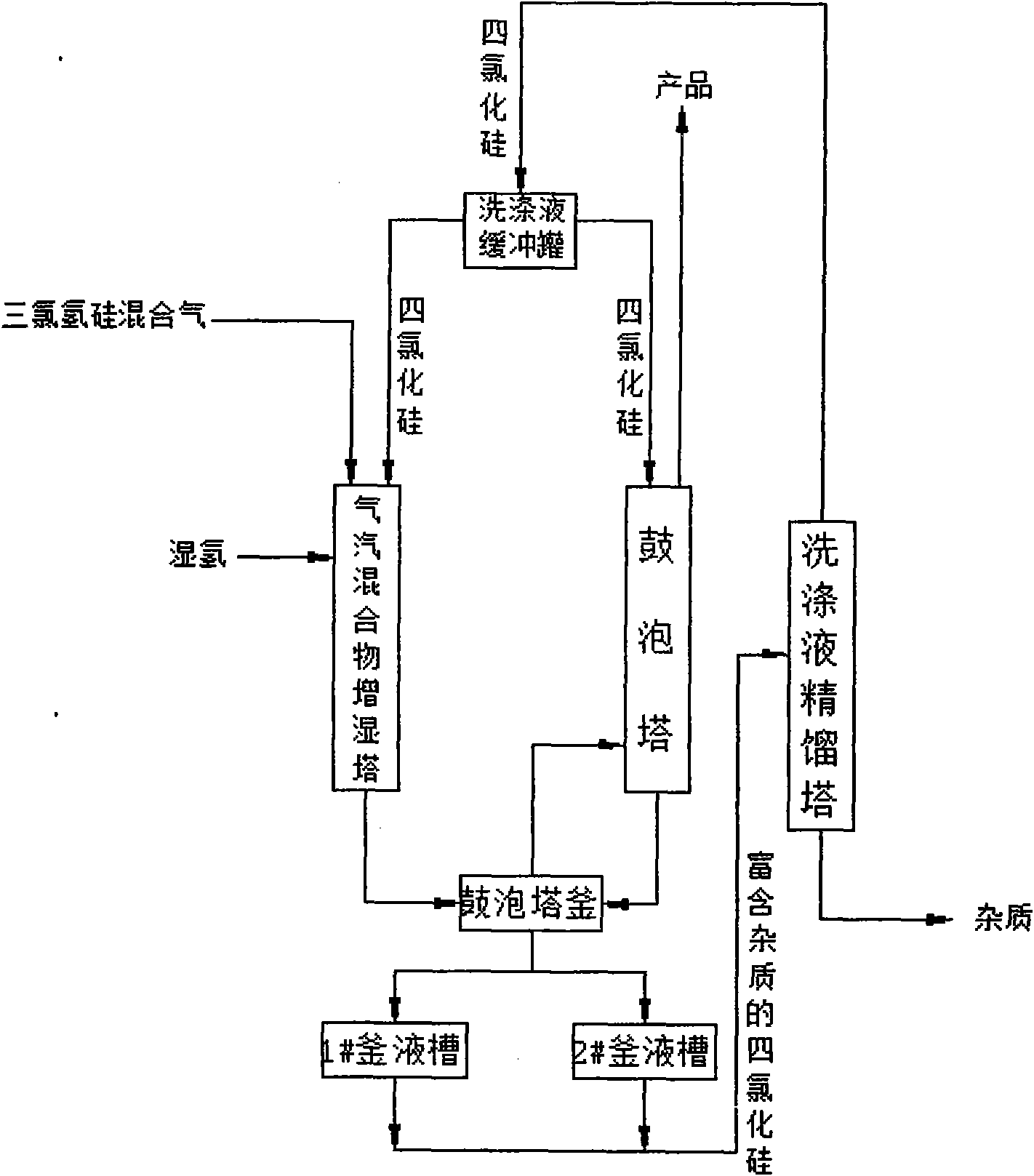

[0029] As shown in Figure 1, the impurity removal treatment method for trichlorosilane mixed gas includes the following steps: firstly, spray trichlorosilane mixed gas with silicon tetrachloride liquid once, and absorb metal chlorides through silicon tetrachloride and silica dust; then pass wet hydrogen into the trichlorosilane mixture to generate SiO 2 , through SiO 2 Adsorb boron (B) and phosphorus (P) in the trichlorosilane mixed gas; finally, the trichlorosilane mixed gas is sprayed with silicon tetrachloride liquid for the second time to further remove metal chlorides to obtain trichlorosilane Hydrogen-silicon synthesis gas product; at the same time, the silicon tetrachloride obtained after two spraying treatments is subjected to rectification and purification treatment, and is recycled for the spraying process.

[0030] The first spraying is to use the silicon tetrachloride liquid purified and refined by the 2-stage silicon tetrachloride purification tower to spray the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com