Bio-medicinal porous titanium material and preparation method thereof

A biomedical, porous titanium technology, applied in medical science, prosthesis, etc., can solve the problems of insufficient strength of high-porosity porous titanium, loosening or fracture of implants, and mismatch of mechanical properties of titanium and titanium alloys with natural bone, etc. To achieve the effect of reducing stress shielding problems and reducing the problem of insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The biomedical porous titanium material in this example includes 15 layers, and the porosity increases layer by layer from the inside to the outside, as follows: (innermost layer) 0%, 5%, 10%, 15%, 20%, 25% , 30%, 35%, 40%, 45%, 50%, 55%, 60%, 65%, (the outermost layer) 70%, the pore diameter is 100μm-300μm; the length, width and height of the material are respectively 30mm, 20mm, 10mm flat plate; the thickness of each layer (in the same direction) is the same.

[0037] The biomedical porous titanium material of this example is prepared by a method comprising the following steps:

[0038] (1), mixing materials:

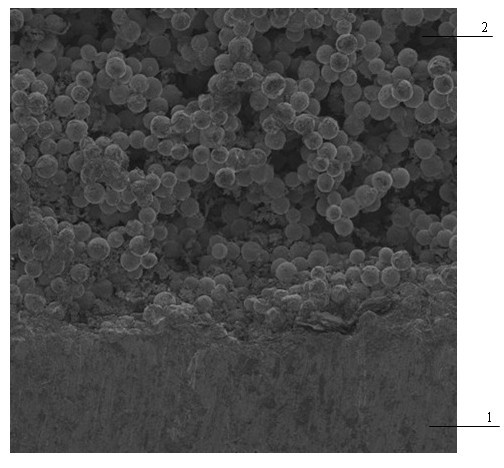

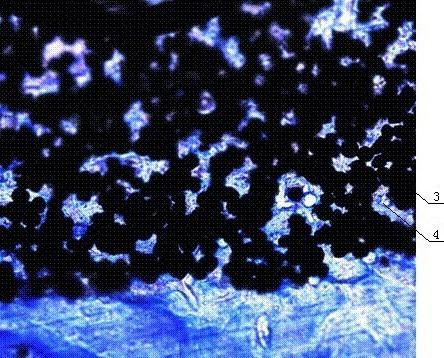

[0039] The part with 0% porosity in the innermost layer directly selects Ti with high mechanical properties and good biocompatibility. 6 Al 7 Nb titanium alloy plate is used as raw material; the rest of the layers are prepared according to the above-mentioned porosity: raw material titanium powder (atomized spherical titanium powder with a particle size of 50 ...

Embodiment 2

[0047] The biomedical porous titanium material in this example includes 11 layers, and the porosity increases layer by layer from the inside to the outside, as follows: (innermost layer) 0%, 5%, 10%, 15%, 20%, 25% . (in the same direction) the same.

[0048] The biomedical porous titanium material of this example is prepared by a method comprising the following steps:

[0049] (1), mixing materials:

[0050] Prepare raw material titanium powder (biomedical spherical atomized titanium powder with a particle size of 30 μm) and pore-forming agent (sodium chloride) with a particle size of 50 μm-200 μm according to the different porosities of the above layers, pore-forming agent and raw titanium powder The proportion of the amount used is calculated according to the porosity of each layer; the pore-forming agent and the raw material titanium powder are evenly mixed to obtain a composite material of the pore-forming agent and the raw material titanium powder;

[0051] (2), fillin...

Embodiment 3

[0060] The biomedical porous titanium material in this example includes 10 layers, and the porosity increases layer by layer from the inside to the outside, as follows: (innermost layer) 0%, 10%, 20%, 30%, 40%, 50% .

[0061] The biomedical porous titanium material of this example is prepared by a method comprising the following steps:

[0062] (1), mixing materials:

[0063] Prepare raw titanium powder (atomized spherical titanium powder with a particle size of 50 μm) and a pore-forming agent (urea) with a particle size of 200 μm-400 μm according to the different porosities of the above-mentioned layers, and the ratio of the amount of the pore-forming agent to the raw titanium powder is respectively Calculate according to the porosity of each layer; mix the pore-forming agent and raw titanium powder evenly to obtain a composite material of pore-forming agent and raw titanium powder;

[0064] (2), filling, pre-pressing molding:

[0065] Fill the pore-forming agent and raw t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com