A clamping and strengthening method for prefabricated concrete hole hollow slab bridges

A hollow slab bridge and concrete technology, used in bridge reinforcement, erection/assembly of bridges, bridges, etc., can solve problems such as reducing the reinforcement performance of steel beams to hollow slab girder, achieve good reinforcement performance, reduce excessive strength or, Choose Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

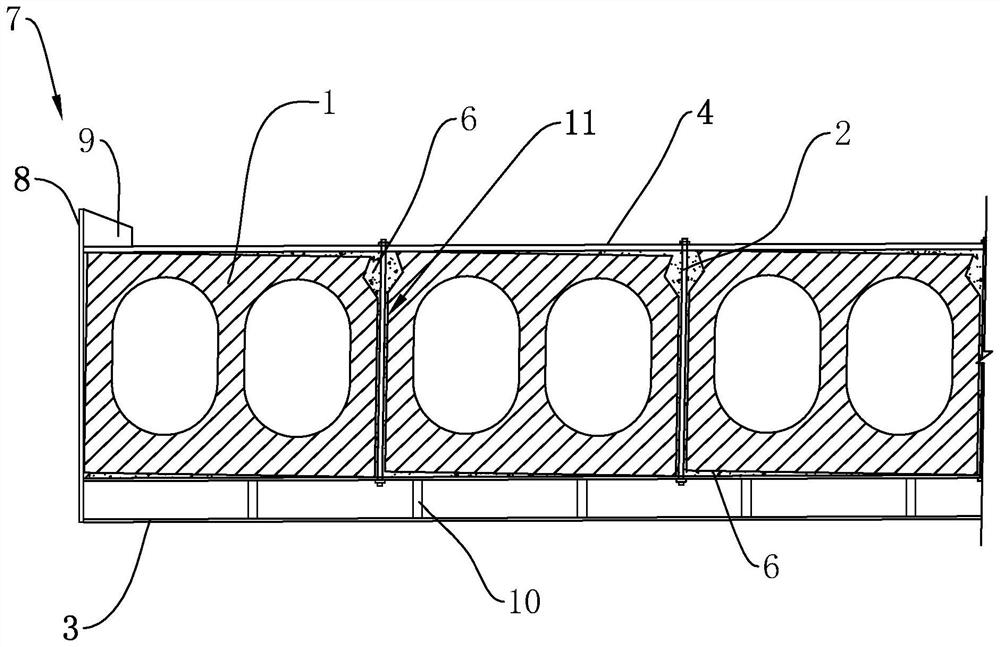

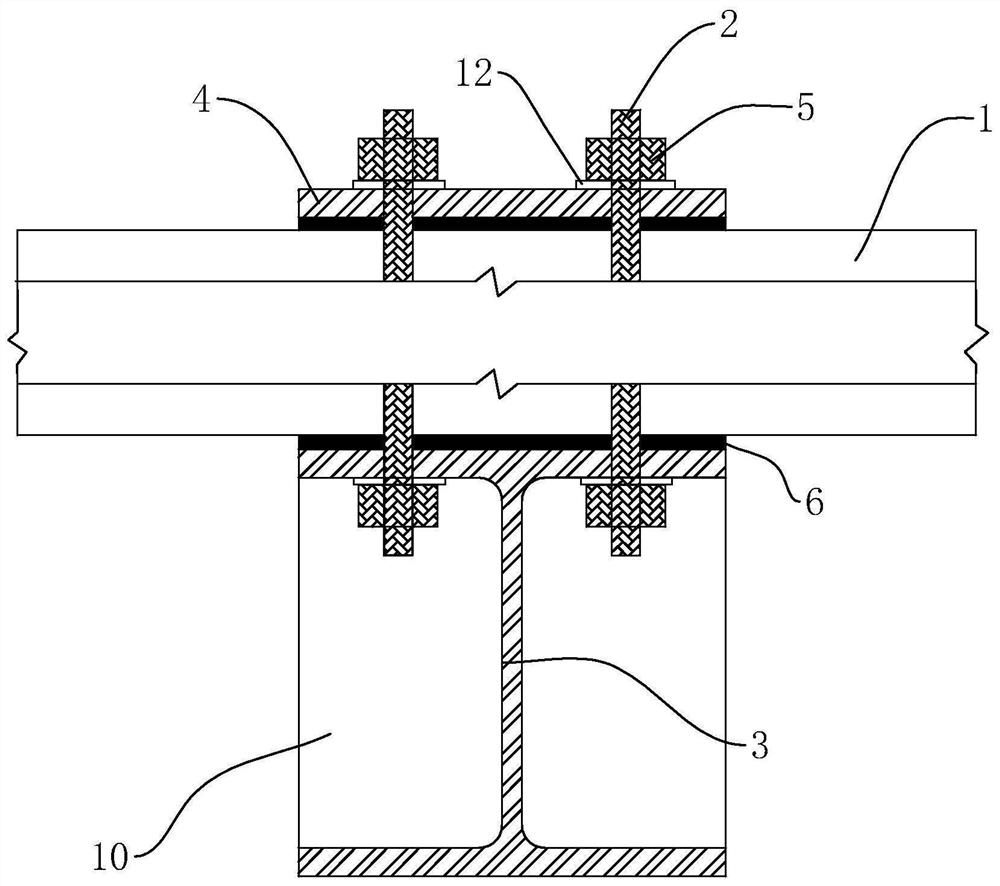

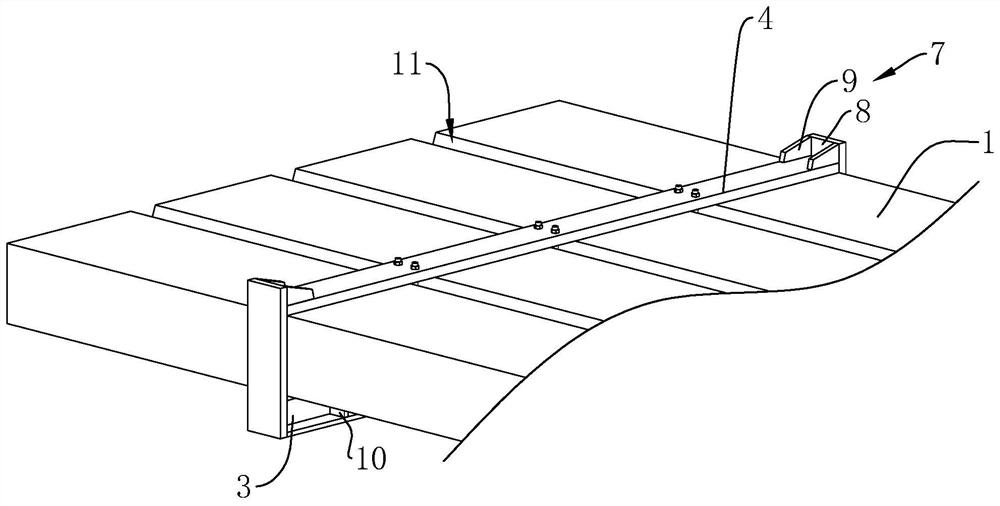

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] refer to figure 1 and figure 2 , is a clamping reinforcement method for a prefabricated concrete hole hollow slab bridge disclosed in the present invention, the hollow slab bridge includes a plurality of parallel and parallel arranged hollow slab beams 1, and the fulcrum distance between the two ends of the hollow slab beams 1 is 5m-25m , that is, the span of the hollow slab bridge. There is a hinged joint 11 between two adjacent hollow slab beams 1, and the concrete poured in the hinged joint 11 is used to connect the two hollow slab beams 1 relative to each other. Since the concrete in the hinged joint 11 is overloaded for a long time, The concrete is cracked, thereby causing the connection between two adjacent hollow slab beams 1 to fall off. When strengthening, it is necessary to remove the old concrete in the hinge joint 11 first, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com