Processing method of polyvinyl chloride coated tarpaulin

A processing method and polyvinyl chloride technology, applied in the field of tarpaulin, can solve the problems of low seam peeling strength, lack of weather resistance, shading and other properties, poor air tightness, etc., and achieve excellent shading performance and weather resistance, shading and weather resistance. Excellent performance, reducing the effect of insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

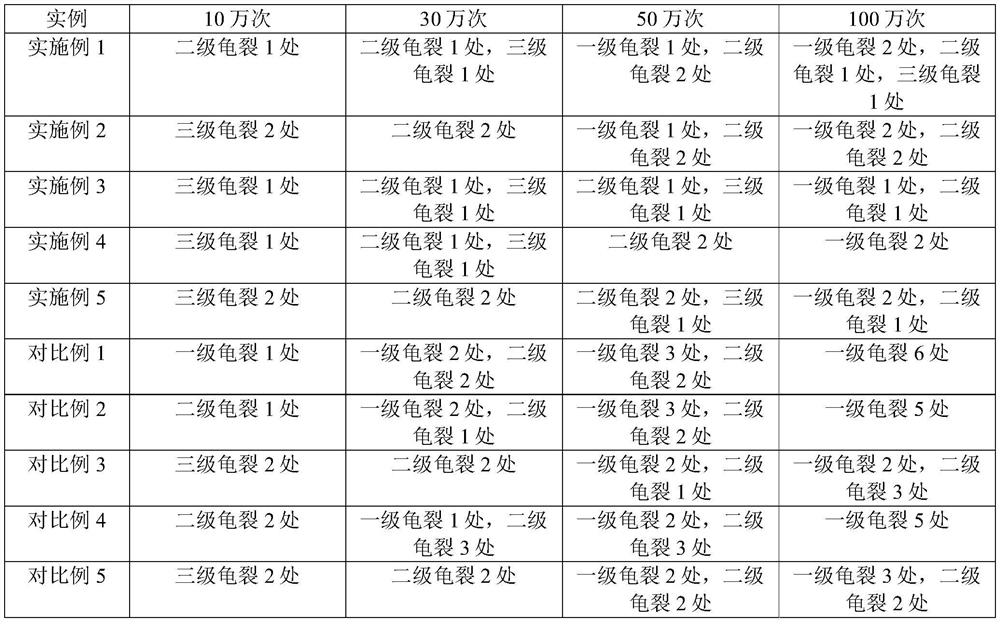

Examples

Embodiment 1

[0034] A processing method for polyvinyl chloride coated tarpaulin, comprising the following steps:

[0035] (1) Pulping: mixing polyvinyl chloride paste resin, dioctyl phthalate, polyurethane, viscosity reducer D80, and tributyl phosphate to obtain slurry A, wherein the beating time is 5 minutes;

[0036] (2) Clothing and slurrying: after the polyester mesh is pressed and rolled, the slurry A is evenly coated on the surface and bottom layer of the polyester mesh;

[0037] (3) Drying: drying the polyester mesh cloth coated with slurry A at 160°C;

[0038] (4) Film preheating: heating the polyvinyl chloride film to a molten state;

[0039] (5) Bonding: The melted polyvinyl chloride film and the dried polyester mesh are placed at 170°C with a pressure of 20kg / cm 2 Heat and pressurize under the same conditions to make a coated tarpaulin;

[0040] (6) Cooling and shaping: Cool the coated tarpaulin.

[0041] Among them, the raw materials of slurry A are calculated in parts by w...

Embodiment 2

[0043] A processing method for polyvinyl chloride coated tarpaulin, comprising the following steps:

[0044] (1) Pulping: mixing polyvinyl chloride paste resin, dioctyl phthalate, polyurethane, viscosity reducer D80, and tributyl phosphate to obtain slurry A, wherein the beating time is 20 minutes;

[0045] (2) Clothing and slurrying: after the polyester mesh is pressed and rolled, the slurry A is evenly coated on the surface and bottom layer of the polyester mesh;

[0046] (3) Drying: drying the polyester mesh cloth coated with slurry A at 180°C;

[0047] (4) Film preheating: heating the polyvinyl chloride film to a molten state;

[0048] (5) Bonding: The melted polyvinyl chloride film and the dried polyester mesh are placed at 180°C with a pressure of 50kg / cm 2Heat and pressurize under the same conditions to make a coated tarpaulin;

[0049] (6) Cooling and shaping: Cool the coated tarpaulin.

[0050] Among them, the raw materials of the slurry A are calculated in parts ...

Embodiment 3

[0052] A processing method for polyvinyl chloride coated tarpaulin, comprising the following steps:

[0053] (1) Pulping: mixing polyvinyl chloride paste resin, dioctyl phthalate, polyurethane, viscosity reducer D80, and tributyl phosphate to obtain slurry A, wherein the beating time is 10 minutes;

[0054] (2) Clothing and slurrying: after the polyester mesh is pressed and rolled, the slurry A is evenly coated on the surface and bottom layer of the polyester mesh;

[0055] (3) Drying: drying the polyester mesh cloth coated with slurry A at 170°C;

[0056] (4) Film preheating: heating the polyvinyl chloride film to a molten state;

[0057] (5) Bonding: The melted polyvinyl chloride film and the dried polyester mesh are placed at 175°C with a pressure of 30kg / cm 2 Heat and pressurize under the same conditions to make a coated tarpaulin;

[0058] (6) Cooling and shaping: Cool the coated tarpaulin.

[0059] Among them, the raw materials of the slurry A are calculated in parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com