Transition metal composite oxide catalytic material and microwave preparation method thereof

A composite oxide and transition metal technology, applied in the field of electrochemistry, can solve the problems of difficult control, complex preparation process, and difficulty in nanoscale transition metal spinel-type composite oxides, and achieves fast heating speed, uniform distribution, increased The effect of product specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

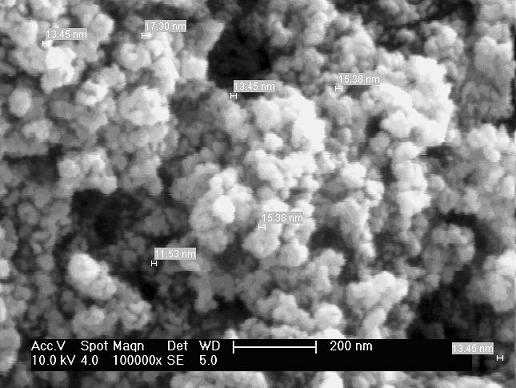

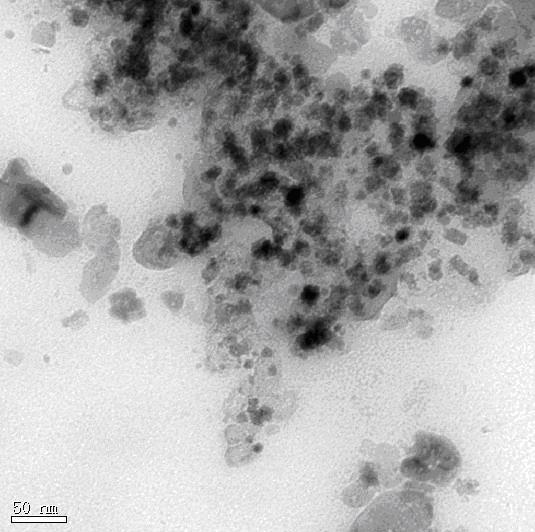

[0034] (1) Press CoMn 2 o 4 stoichiometric ratio (Co:Mn molar ratio 1:2), weigh cobalt nitrate (Co(NO 3 ) 2 6H 2 O) 2.91g (0.01mol) and manganese nitrate (Mn(NO 3 ) 2 ) 3.58g (0.02mol), add 3.6g of distilled water (the molar ratio of distilled water and Co is 20:l) to form a solution, and magnetically stir until the nitrate is fully dissolved. Then add 1.6g of Cabot's Vulcan XC-72 product, stir for 1 hour, centrifuge to collect the precipitate, wash the precipitate, put it in an oven at 75°C for 24 hours, and then grind it into powder to obtain the precursor.

[0035] (2) Heat the precursor in a microwave oven for 140s at a microwave power of 750W to obtain CoMn 2 o 4 It is a catalytic material with catalytically active components and Vulcan XC-72 as a carrier.

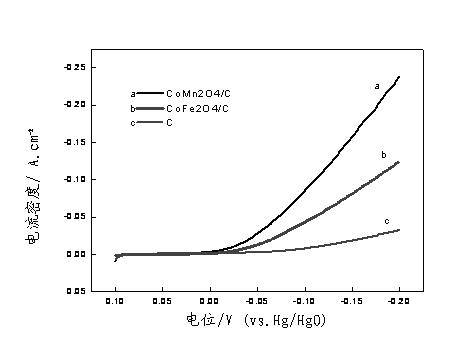

[0036] (3) The obtained catalytic material is made into an air electrode according to the traditional method, and this is used as the positive electrode, the zinc sheet is used as the negative electrode, and 7mo...

Embodiment 2

[0038] (1) Press CoFe 2 o 4 The stoichiometric ratio (Fe to Co molar ratio 2:1) Weigh 0.02mol of ferric nitrate and 0.01mol of cobalt nitrate, add 3.6g of distilled water to make a solution (the molar ratio of distilled water to Fe is 20:l), magnetic stirring When the nitrate is fully dissolved, add 1.6g of Cabot’s Vulcan XC-72 product, stir magnetically for 1.5 hours, centrifuge to collect the precipitate, wash the precipitate, put it in an oven at 75°C and fully dry it for 24 hours, then grind it into powder. That is, the precursor is obtained.

[0039] (2) Heating the precursor in a microwave oven for 210s at a microwave power of 750W yields CoFe 2 o 4 It is a catalytic material with active ingredient and Vulcan XC-72 as carrier.

[0040] (3) The obtained catalytic material is made into an air electrode according to the traditional method, and this is used as the positive electrode, the zinc sheet is used as the negative electrode, and 7mol / L KOH is used as the electrol...

Embodiment 3

[0042] (1) Press MnCo 2 o 4 The stoichiometric ratio (Mn to Co molar ratio 1:2) Weigh 0.01mol of manganese acetate and 0.02mol of cobalt acetate (both AR), add 3.6g of distilled water to make a solution, add 10ml according to the stoichiometric ratio, the concentration is 3.6 mol / L ammonium oxalate (AR) solution (excess 20%) was reacted under constant stirring for 1 hour, and then centrifuged to collect the precipitate. The precipitate was washed and dried at 75°C. The resulting solid product mixture of cobalt oxalate and manganese oxalate was the precursor.

[0043] (2) Add 1.6g of microwave absorbing agent acetylene black to the precursor, then add absolute ethanol and stir until it becomes a paste, dry it at 60°C, grind it into powder, and heat it in a microwave oven with a microwave power of 320W for 80s. MnCo 2 o 4 It is a catalytic material with active ingredient and acetylene black as carrier.

[0044] (3) The obtained catalytic material is made into an air diffusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com