Tea drying equipment and process

A drying equipment and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems affecting the drying effect of tea and uneven heating of tea, so as to improve the efficiency of heat utilization, avoid uneven heating and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

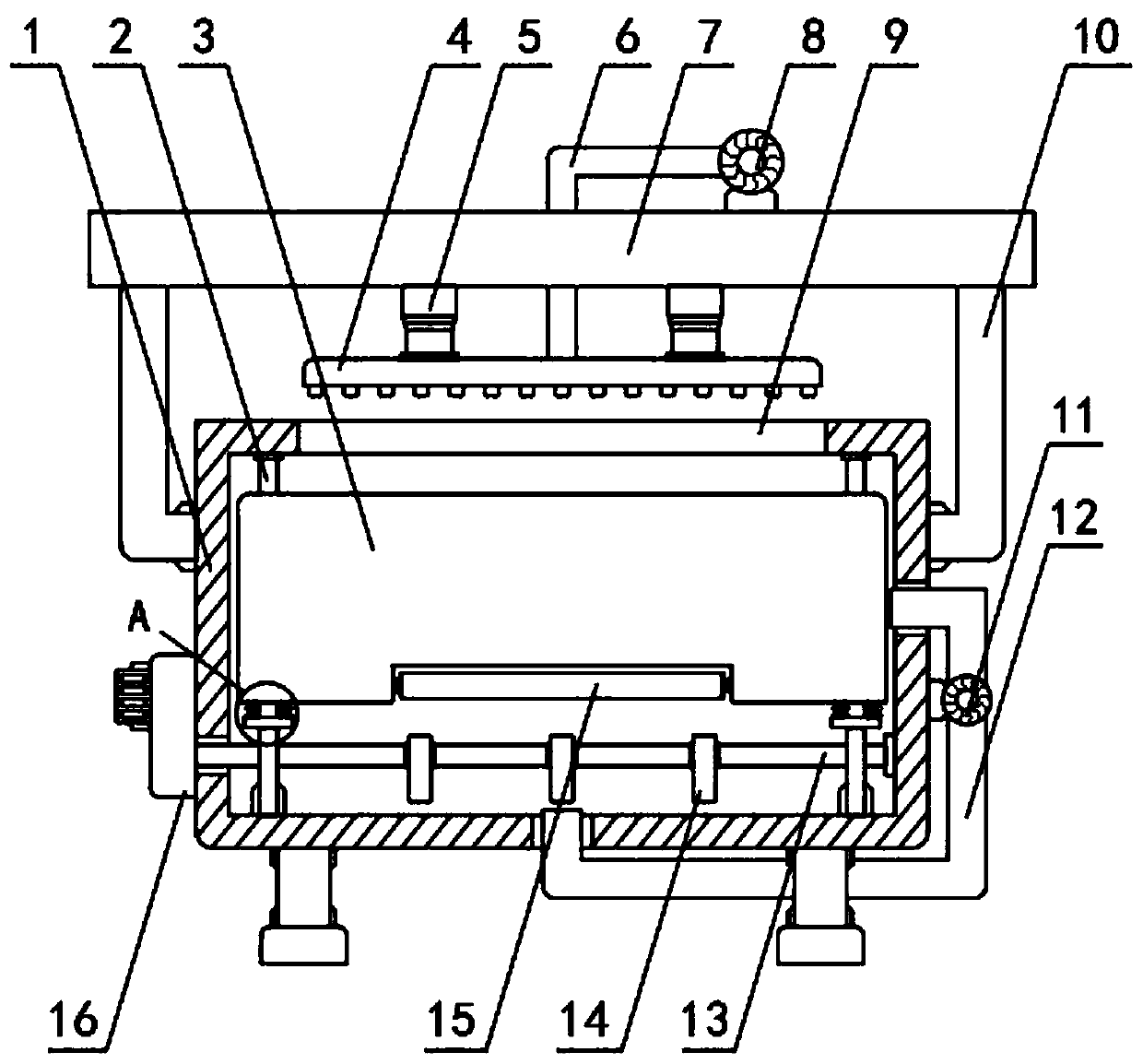

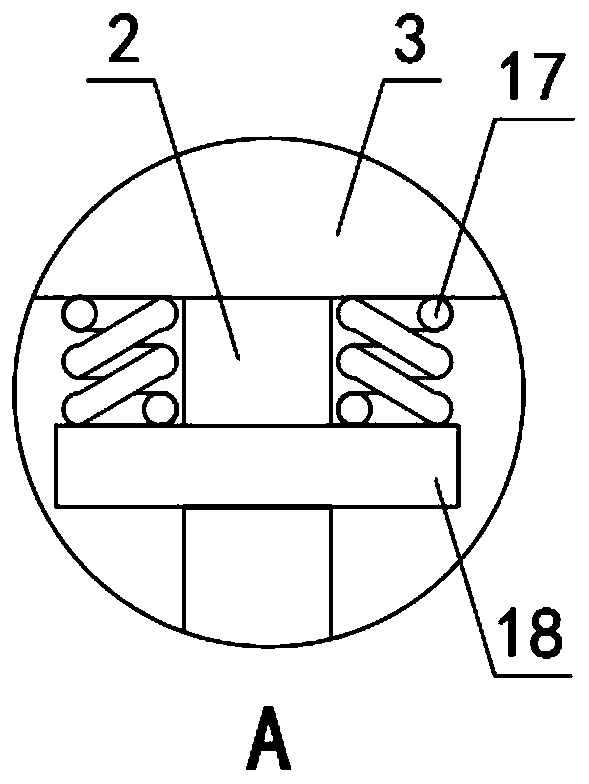

[0037] see Figure 1-4 , a kind of tea drying equipment, comprising a drying box 1, a hot air blower 8, a drying rack 4 and an opening 9, the inside of the drying box 1 is provided with a placement frame 3, and the inner surface wall of the placement frame 3 is fixed with Place the net 20, the place net 20 is used for the placement of tea leaves, the four corners of the placement frame 3 are slidingly embedded with slide bars 2, and the slide bars 2 are fixed between the inner surface walls of the vertical end of the drying box 1. The rod 2 and the placement frame 3 are clearance fit, the placement frame 3 can move in the vertical direction, the slide bar 2 can prevent the displacement of the placement frame 3 in the vertical direction, the placement frame 3 and the drying box 1 A rotating shaft 13 in the horizontal direction is arranged between the inner and outer walls of the bottom, and a cam 14 is sleeved on the rotating shaft 13. The cam 14 and the rotating shaft 13 are i...

Embodiment 2

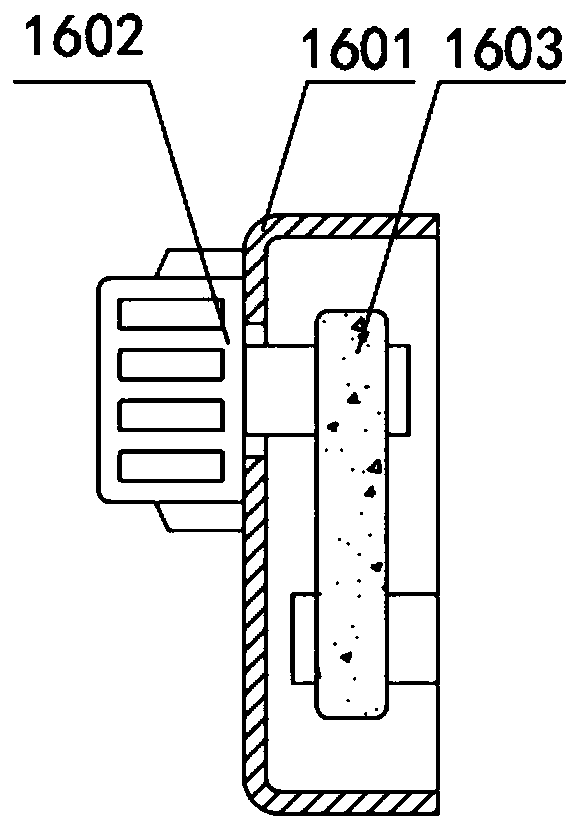

[0039] see figure 2 , the driving mechanism 16 includes a protective cover 1601, a motor 1602 is fixed on the side wall of the protective cover 1601, the rotating shaft 13 runs through the side wall of the drying box 1, and extends to the inner cavity of the protective cover 1601, the output shaft of the motor 1602 and the rotating shaft 13 is connected by a belt 1603 transmission, the output shaft of the motor 1602 can pass the belt 1603 to make the rotating shaft 13 rotate, and the lower surface wall of the placement frame 3 is connected with a rotating roller 15 through the rotating shaft, and the rotating roller 15 avoids the cam 14 and the placement The friction between the lower surface walls of the frame 3 reduces the wear of the placement frame 3 and can effectively improve the service life of the placement frame 3 .

Embodiment 3

[0041] see figure 1 and image 3 , the top of the drying box 1 is fixed with a top plate 7 through the connecting frame 10, the drying frame 4 is located at the bottom of the top plate 7, and an electric telescopic rod 5 is arranged between the drying frame 4 and the top plate 7, and the electric telescopic rod 5 can drive the drying The drying frame 4 moves in the vertical direction, and the inner surface wall of the bottom of the placement frame 3 is provided with a ventilation hole 19, and the outside of the drying box 1 is provided with a circulation pipe 12, and the circulation pipe 12 is embedded in the bottom of the drying box 1 On the inner surface wall and the side wall, an exhaust fan 11 is installed on the circulation pipe 12. Under the action of the exhaust fan 11, the hot air flow can wrap the placement frame 3, which can effectively carry out secondary use of the hot air flow and contribute to Drying of tea leaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com