Preparation method of MnAsP compound with efficient room temperature magnetic refrigeration performance

A compound and magnetic refrigeration technology, applied in the field of new functional materials, can solve problems such as difficult control of components, high thermal hysteresis, and difficulty in preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

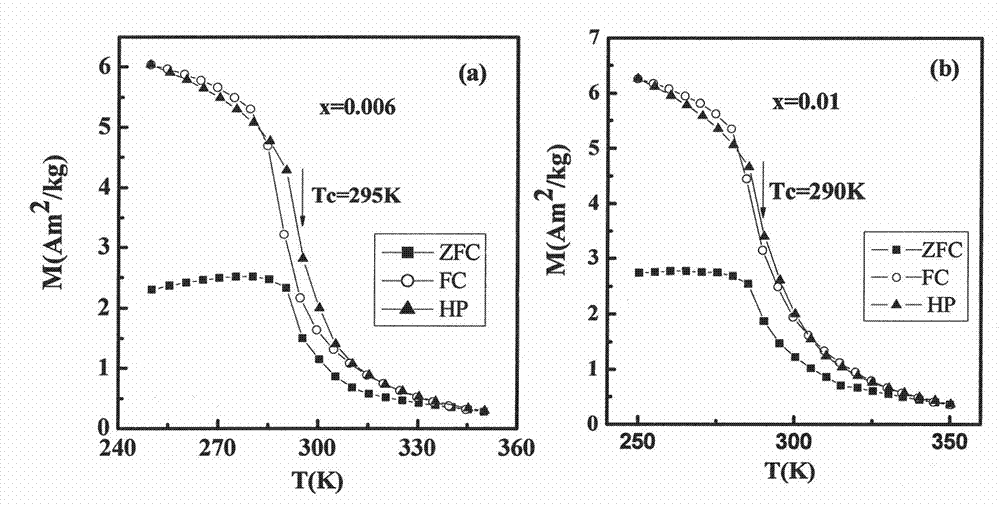

[0018] Mn, As, P powder with a purity of 99.99% are mixed according to MnAs0.994P0.006 and MnAs0.99P0.01 (atomic percentage, at%), and the Figure 1 The shown glove box filled with high-purity argon was placed in a ball mill jar and the jar was sealed. The sealed jar was then taken out of the glove box and placed in Figure II The shown ball milling jar was ball milled for 5 hours, and the ball mill rotating speed was 800 rpm. Then the ball mill jar was opened in the glove box, and the powder was placed in a small crucible Figure 1 Multi-step annealing is performed in the tubular annealing furnace directly connected to the glove box shown, and air-cooled to room temperature after annealing. image 3 is the magnetization curve, indicating that the magnetization value of the zero-field cooling curve is more than two times lower than that of the field cooling, indicating that the size of some particles has reached the nanometer level, and the magnetic moment of these nanoparti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com