Polyester elastomer and preparation method thereof

A technology of elastomers and polyesters, applied in the field of polymer materials, can solve the problems of application limitations of bioelastomers, and achieve the effects of no catalyst, good biocompatibility, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

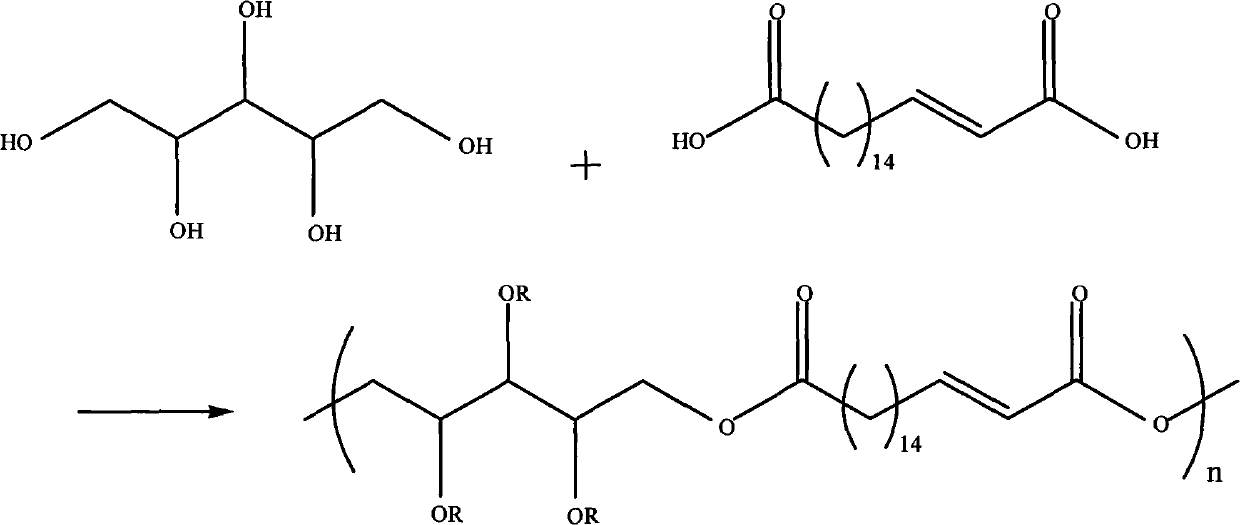

[0035] Weigh a certain amount of monomers (4.50g xylitol, 3.85g itaconic acid) according to the molar ratio of xylitol and itaconic acid 1:1 respectively, add them to a 50mL three-necked flask, vent nitrogen, and oil bath heating control After the temperature is 140°C and the reaction material is completely melted, magnetic stirring is started, and the reaction is kept constant for 4 hours to obtain the prepolymer. Pour the prepolymer into a polytetrafluoroethylene mold for natural leveling, put it in a vacuum oven, and crosslink at 150°C for 14 hours to obtain a polyester elastomer. The chemical reaction formula is:

[0036]

[0037] R: H or -CO(CH 2 ) 6 COO-.

Embodiment 2

[0039] Weigh a certain amount of monomers (4.50g xylitol, 3.54g succinic acid) according to the molar ratio of xylitol and succinic acid at 1:1 respectively, and add them to a 50mL three-necked flask with nitrogen and oil bath heating to control the temperature at After the reaction materials were completely melted at 140°C, magnetic stirring was started, and the reaction was kept at a constant temperature for 9 hours to obtain the prepolymer. Pour the prepolymer into a polytetrafluoroethylene mold and level it naturally, put it in a vacuum oven, and crosslink at 150°C for 24 hours to obtain a polyester elastomer. The chemical reaction formula is:

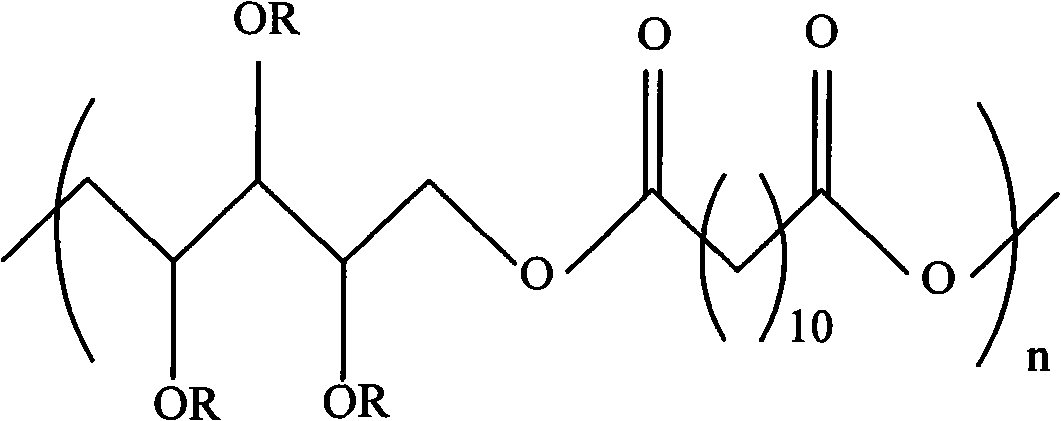

[0040]

[0041] R: H or -CO(CH 2 ) 6 COO-.

Embodiment 3

[0043] Weigh a certain amount of monomers (xylitol 3.32g, dodecanedioic acid 5.02g) according to the molar ratio of xylitol and dodecanedioic acid 1:1, add them to a 50mL three-necked flask, and heat in an oil bath After controlling the temperature at 160°C to completely melt the reaction materials, start magnetic stirring and vacuum, and react at a constant temperature for 20 hours to obtain polyester elastomers. The obtained elastomer is then hot-pressed and cold-pressed by a flat vulcanizer to obtain an elastomer sample, which is cut to prepare a standard sample, and various mechanical performance tests are performed. The results are shown in Table 1. The chemical reaction formula is:

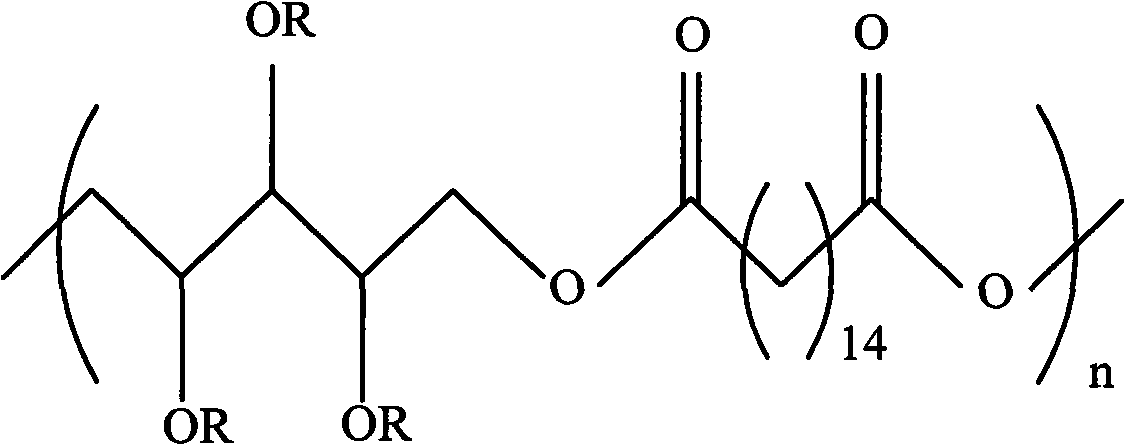

[0044]

[0045] R: H or -CO(CH 2 ) 6 COO-.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com