Cooling Raymond mill and preparation method of powder for pressing graphite products

A Raymond mill and powder technology, which is used in lighting and heating equipment, grain processing, fixed tubular conduit components, etc. Non-uniformity, high energy consumption per ton of output, etc., to avoid poor cooling effect, improve grinding efficiency, and reduce wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

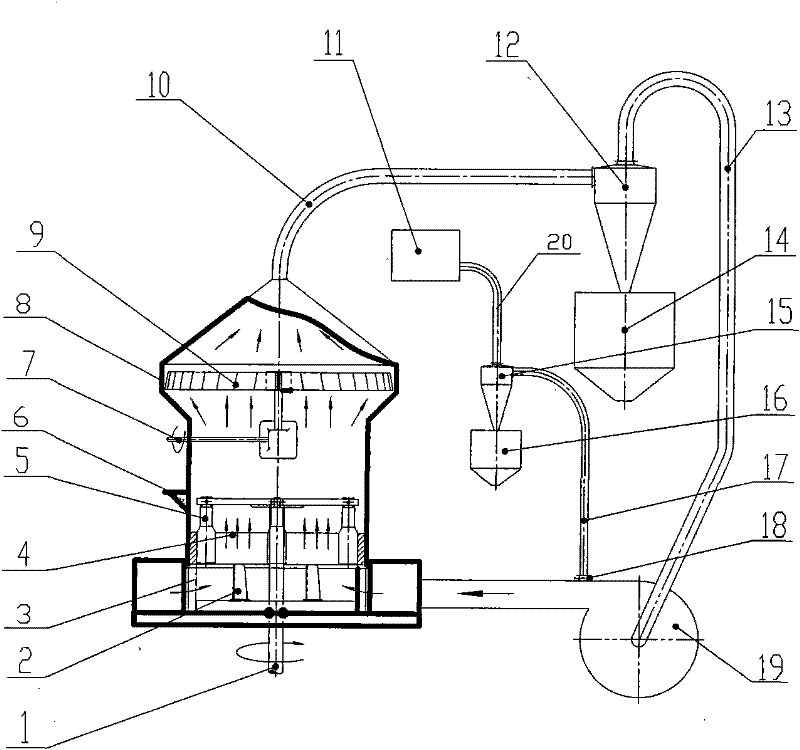

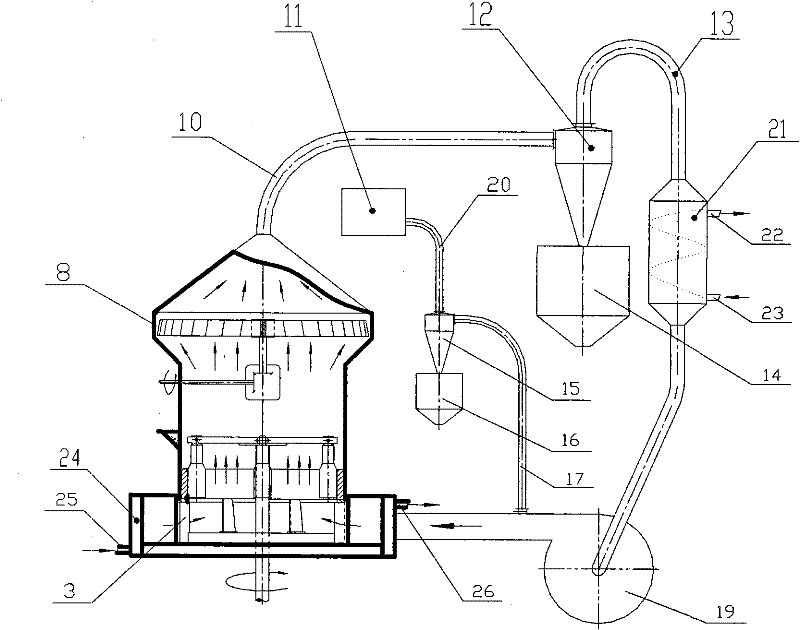

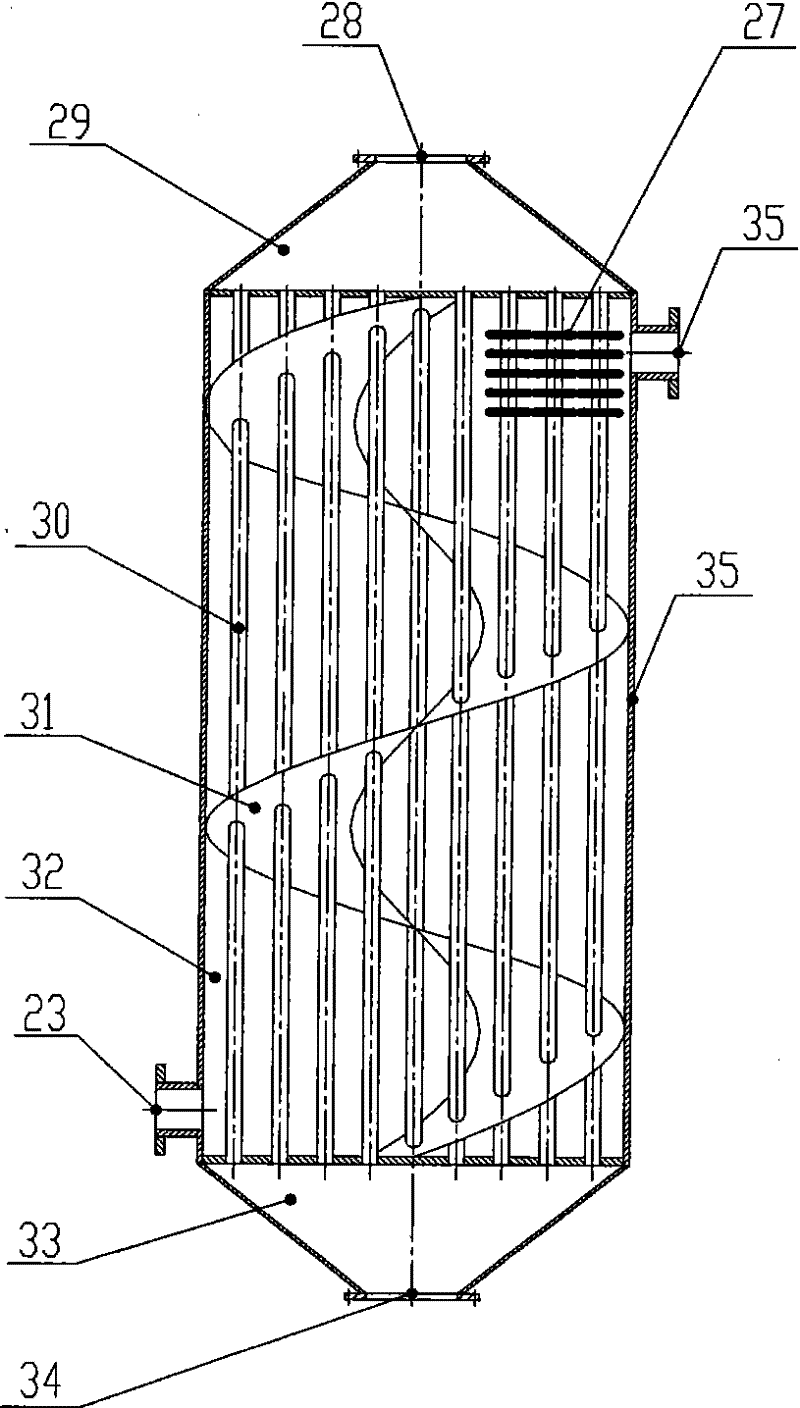

[0039] A kind of cooling Raymond mill of embodiment 1, see figure 1 , figure 2 , image 3 , comprising a host computer 3, an analyzer 8, a cyclone collector 12, and a blower fan 19, each part is connected by air ducts 10 and 13 in turn to form a circulating air path, and the return air pipeline 13 between the cyclone collector 12 and the blower fan 19 A cooling device 21 for cooling the circulating air flow is also installed in the middle, and the cooling device 21 includes sixty-two heat exchange branch pipes 30, a cooling chamber 32, a spiral deflector 31, an air inlet chamber 29, an air outlet chamber 33, a housing 35. Sixty-two heat exchange branch pipes are vertically and evenly arranged on the multi-layer concentric circle in the cooling chamber 22, and their upper and lower ports are respectively connected to the air inlet chamber 29 and the air outlet chamber 33. The heat exchange branch pipes 30 The specifications are Φ55mm, 2mm thick, and 1m long thin-walled coppe...

Embodiment 2

[0044] Embodiment 2 A cooling Raymond mill, which is basically the same as Embodiment 1, the difference is that: no cooling jacket is provided outside the shell of the main grinding roller chamber of the main engine; the heat exchange branch pipe is a thin-walled aluminum pipe; all heat exchange branch pipes The sum of the cross-sectional areas is 3 times of the cross-sectional area of the air duct between the cyclone collector 9 and the blower fan 16.

[0045] Utilize above-mentioned cooling Raymond mill to prepare the method for the used powder of pressed graphite product:

[0046] (1) Pitch coke is selected for primary grinding, and ground into a powder with a particle size of 280 mesh;

[0047] (2) Kneading and sheeting Add asphalt with a softening point of 70-90°C according to 29-31% of the weight of the powder obtained in the previous step, knead and stir at 160-170°C for 50-60 minutes to form a paste, roll Make it into flakes, and after drying and cooling, break into...

Embodiment 3

[0049] Embodiment 3 A cooling Raymond mill, which is basically the same as Embodiment 1, the difference is that no spiral deflector is provided in the cooling cavity; 2 times the cross-sectional area of the air duct between 16.

[0050] Utilize above-mentioned cooling Raymond mill to prepare the method for the used powder of pressed graphite product:

[0051] (1) Primary milling: select pitch coke, grind it into a powder with a particle size of 250 mesh, and add flake graphite according to 5-8%;

[0052] (2) Kneading and sheeting Add asphalt according to 30-32% of the weight of the powder obtained in the previous step, knead and stir at 160-170°C for 55-60 minutes, form a paste, roll it into a sheet, and dry it After cooling, it is broken into fragments with a particle size of ≤15mm, and it is set aside;

[0053] (3) Grinding powder for pressing The fragments obtained in the previous step are sent into the above-mentioned cooling Raymond mill through the vibrating feeder e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com