Novel electrochemical treatment device for wastewater treatment and wastewater treatment method

A technology for wastewater treatment and treatment equipment, which is applied in chemical instruments and methods, water/sewage treatment, flotation water/sewage treatment, etc., and can solve problems such as high cost, high energy consumption, and side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

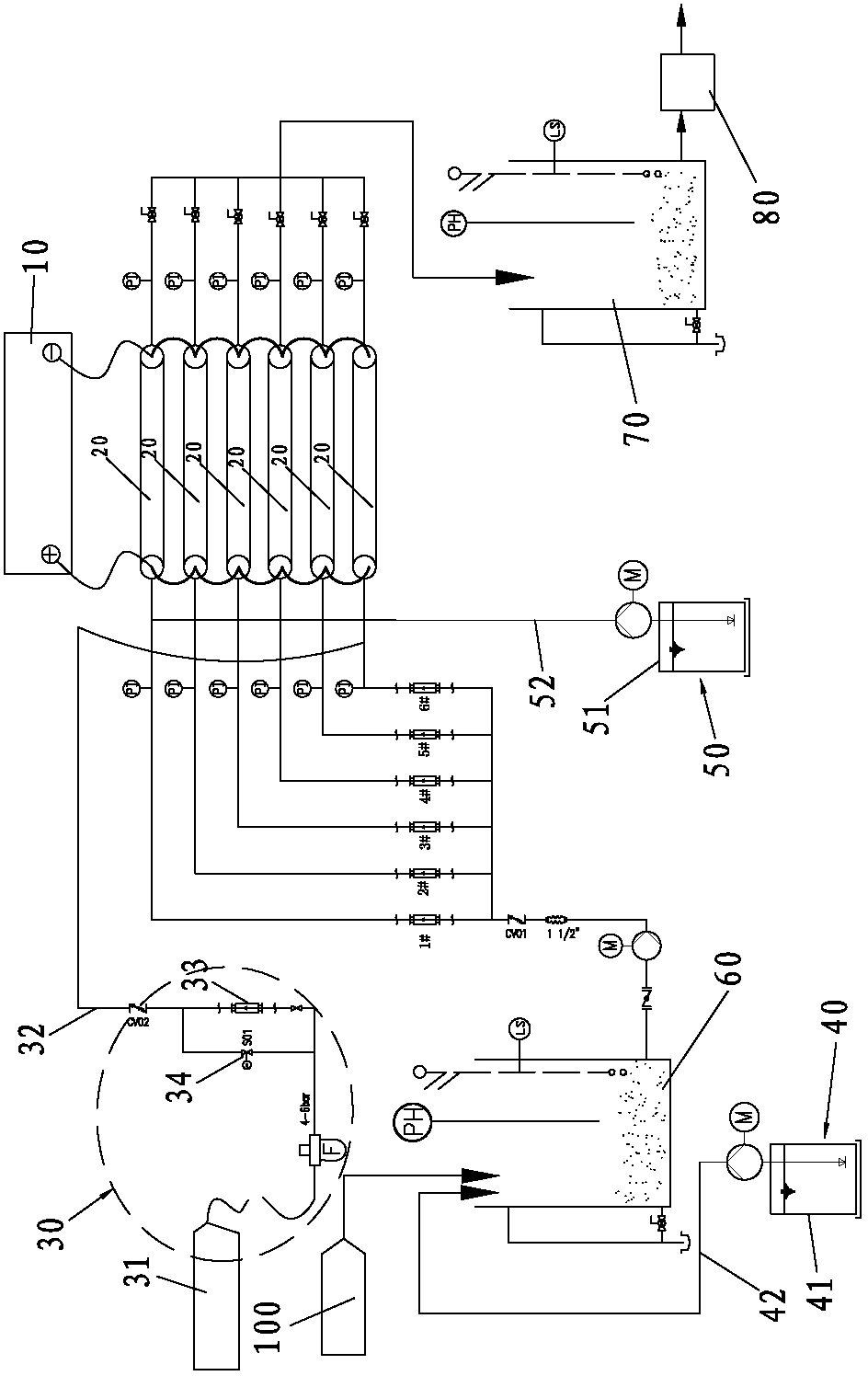

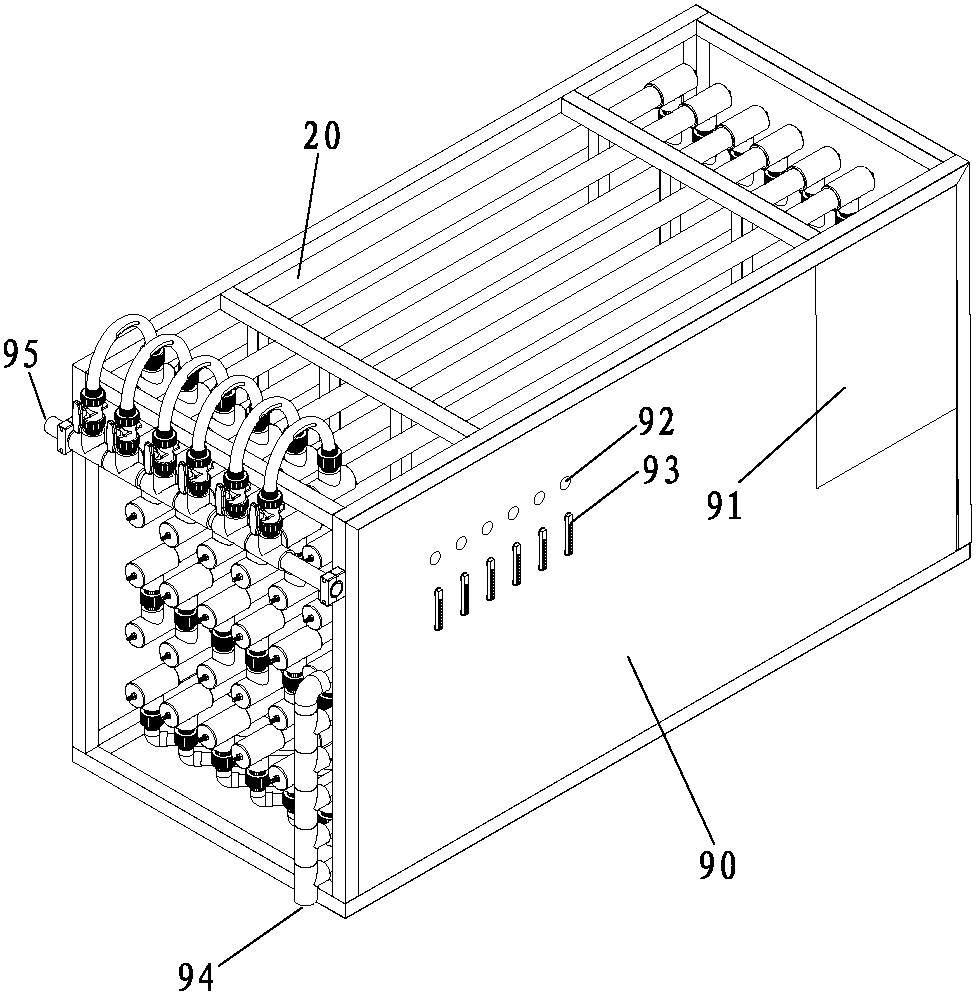

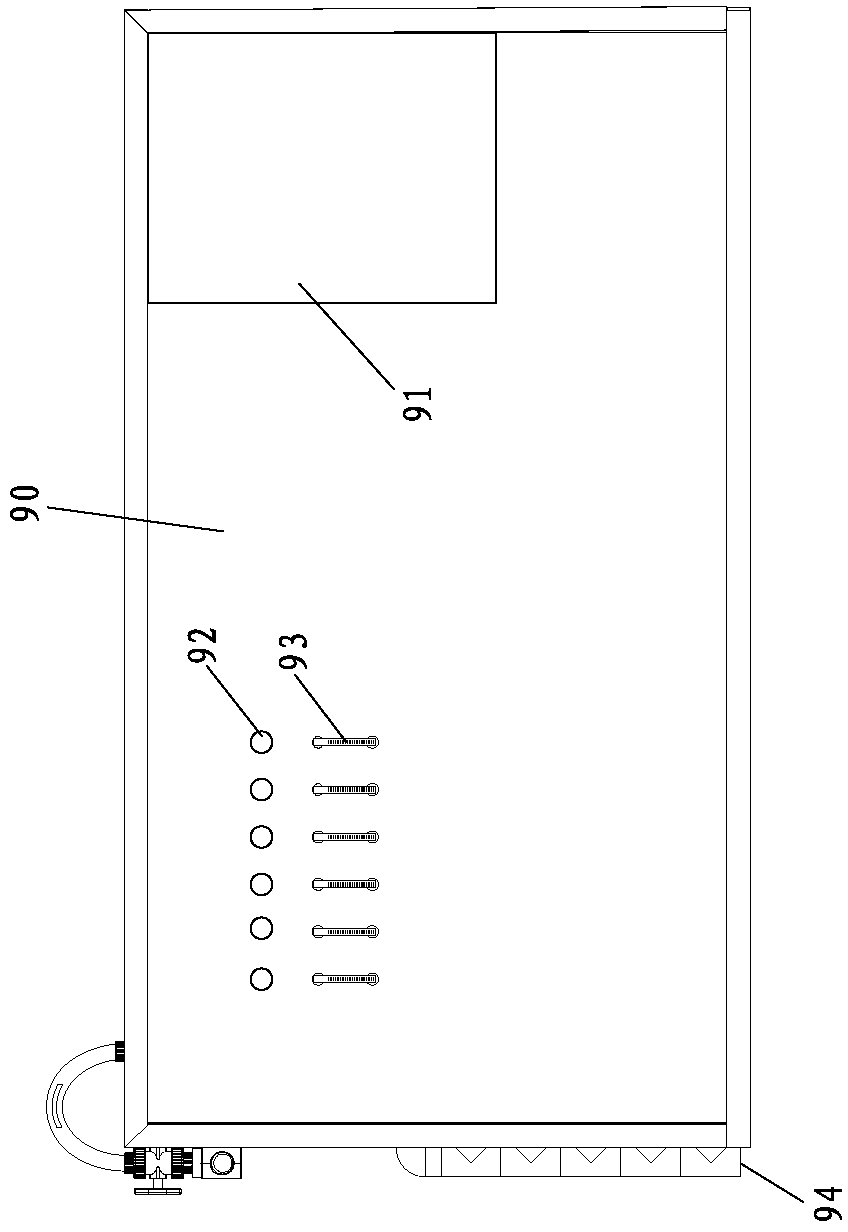

[0045] Please refer to Figure 1 to Figure 6 As shown, it shows the general structure and principle of the preferred embodiment of the present invention, this kind of novel electrochemical treatment equipment for wastewater treatment, it can be widely used in various types of wastewater treatment and water supply treatment projects, such as various Various industrial wastewater (such as electroplating wastewater, printing and dyeing wastewater, circuit board industrial wastewater, semiconductor industrial wastewater, etc.) and landfill leachate treatment, etc.

[0046]The equipment includes a high-frequency pulse power supply 10, an electrochemical reaction device 20, an aeration device 30, a first dosing device 40, a second dosing device 50, a first auxiliary oxidation reaction device 60, and a second auxiliary oxidation reaction device 70. And VF membrane filtration device 80, its overall structure is relatively simple, safe and reliable.

[0047] Among them, the high-frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com