High-temperature resistant carbon fiber heat insulation felt

A technology of thermal insulation felt and high temperature resistance, which is applied in the field of carbon/carbon composite material prefabricated fiber felt, and can solve the problems of poor cohesion of preoxidized fibers, many production processes, and difficulty in continuous production of multiple alternating layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

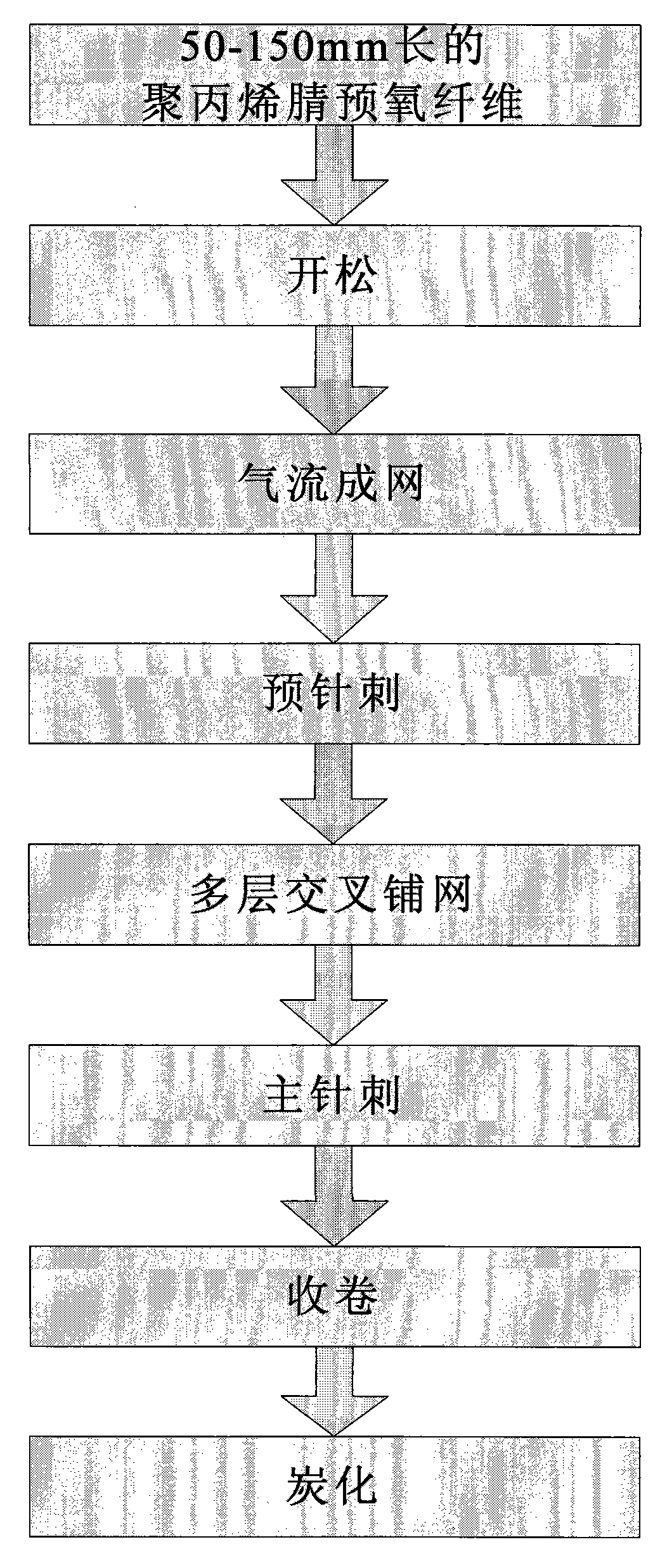

[0064] (1) 320K, the polyacrylonitrile preoxygenated fiber of 10-15 micron wire diameter is cut into the short fiber that length is 100 millimeters through XPD140 type chopping machine.

[0065] (2) Open in the 800 type opener.

[0066] (3) It is transported to the 150B air-laid equipment for air-laid by airflow. Its thickness is 10-30mm net tire.

[0067] The air-laid machine adjusts the air flow rate of 10-20 m / s to adjust the direction of the upper air return of the cotton box and the direction of the nodding, and adjusts the content and arrangement direction of the fibers in the three-dimensional direction, so that the fiber content in the X-Y plane layer is high, and the Z There are few fibers. After the net tire is evenly treated by 3 groups of 6 transfer rollers. And at a speed of 3.6 m / min, it is sent to multiple pressure rollers for rolling to form a thin net tire with a relatively stable density. The content of the layer in the X-Y plane is high, and the weight o...

Embodiment 2

[0080] (1) 320K, the polyacrylonitrile preoxygenated fiber of 10-15 micron wire diameter is cut into the short fiber that length is 100 millimeters through XPD140 type chopping machine.

[0081] (2) Open in the 800 type opener.

[0082] (3) It is transported to the 150B air-laid equipment for air-laid by airflow. Its thickness is 10-30mm net tire.

[0083] The air-laid machine adjusts the air flow rate of 10-20 m / s to adjust the direction of the upper air return of the cotton box and the direction of the nodding, and adjusts the content and arrangement direction of the fibers in the three-dimensional direction, so that the fiber content in the X-Y plane layer is high, and the Z There are few fibers. After the net tire is evenly treated by 3 groups of 6 transfer rollers. And at a speed of 3.6 m / min, it is sent to multiple pressure rollers for rolling to form a thin net tire with a relatively stable density. The content of the layer in the X-Y plane is high, and the weight o...

Embodiment 3

[0095] (1) 320K, the polyacrylonitrile preoxygenated fiber of 10-15 micron wire diameter is cut into the short fiber that length is 100 millimeters through XPD140 type chopping machine.

[0096] (2) Open in the 800 type opener.

[0097] (3) It is transported to the 150B air-laid equipment for air-laid by airflow. Its thickness is 10-30mm net tire.

[0098] The air-laid machine adjusts the air flow rate of 15 m / s to adjust the direction of the upper air flow of the cotton box and the direction of the nodding, and adjusts the content and arrangement direction of the fibers in the three-dimensional direction, so that the fiber content in the X-Y plane layer is high, and the Z-direction fiber content is high. rare. After the net tire is evenly treated by 3 groups of 6 transfer rollers. It is sent to multi-channel press rollers at a speed of 3.6 m / min to form a thin mesh tire with stable relative density. The press pressure is 35 kg, and the fiber content in the X-Y plane layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chopped length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com