Centrifugal double-channel trace liquid quantitative sampling device and manufacturing method thereof

A technology of trace liquid and sample introduction device, which is applied in sampling device, preparation of test samples, photoengraving process of pattern surface, etc. The effect of simple process, low cost and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

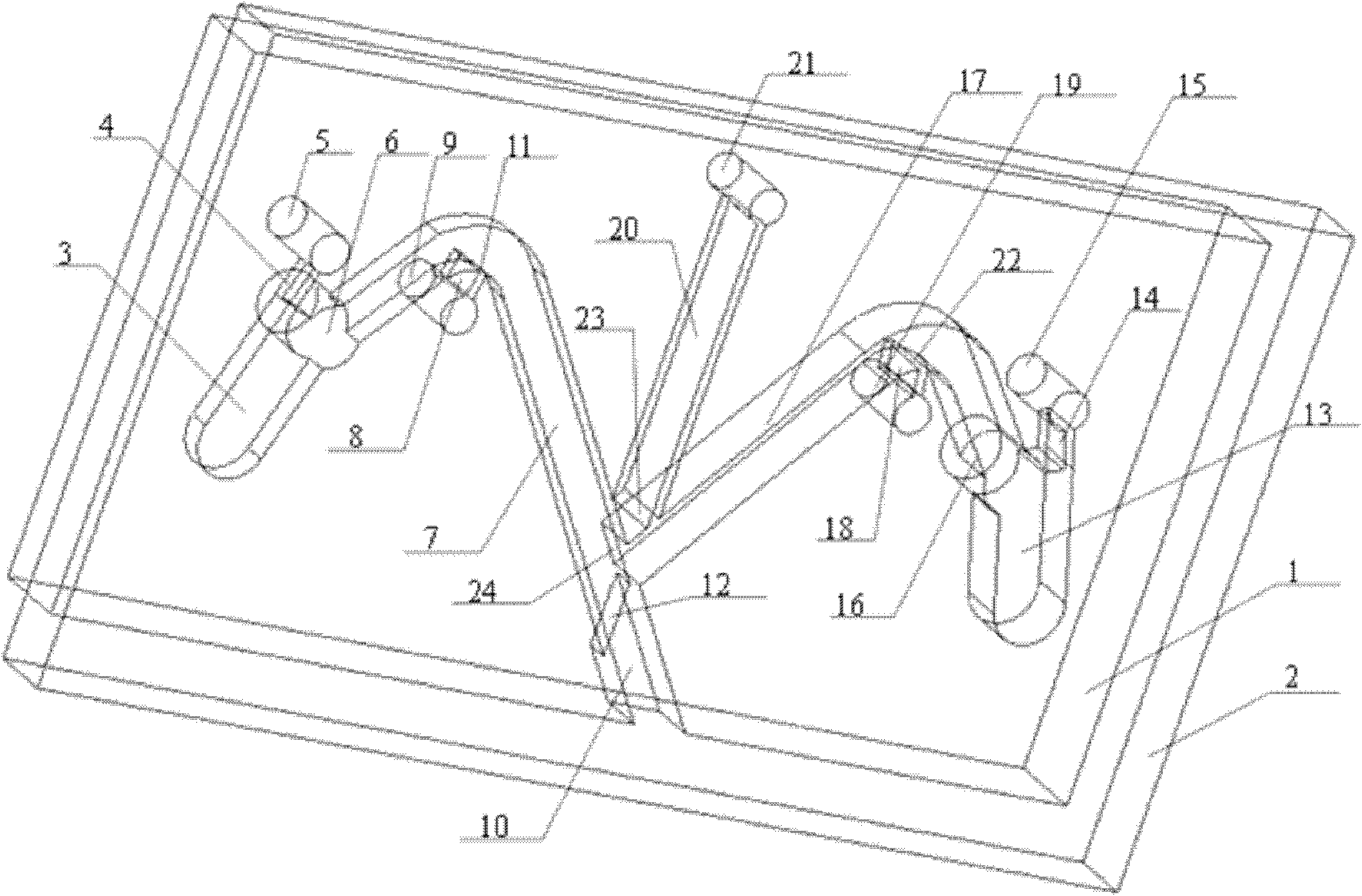

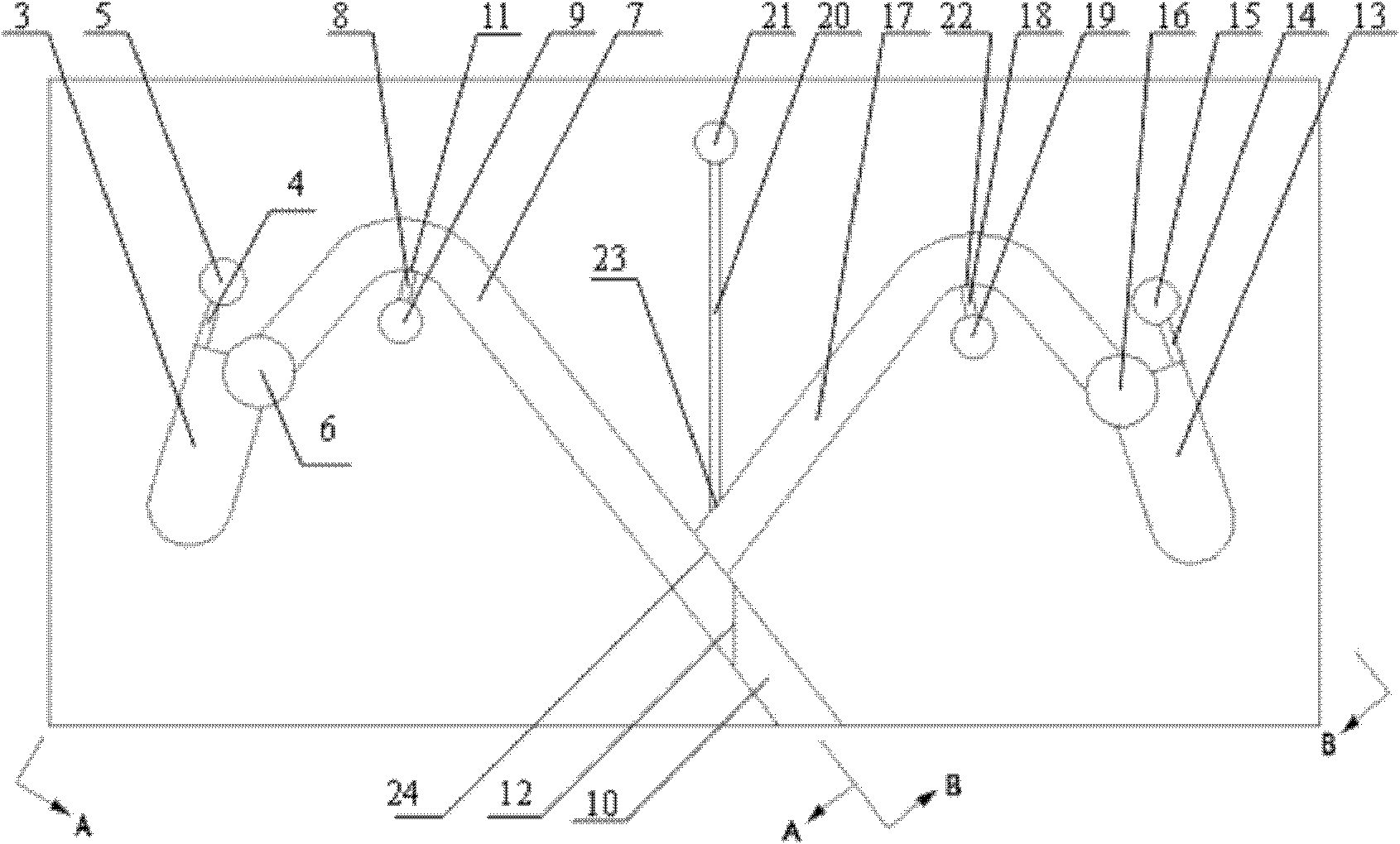

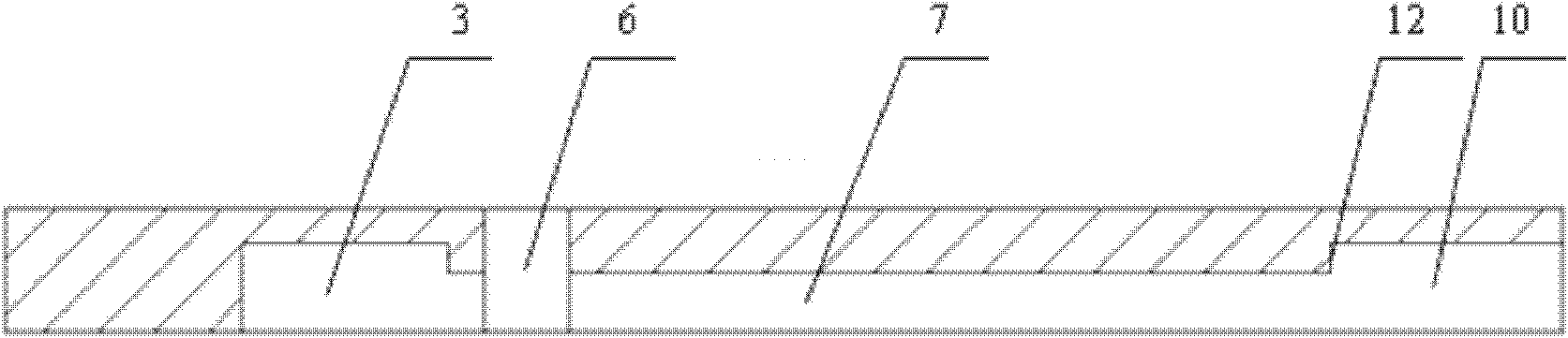

[0028] Specific implementation mode 1. Combination Figure 1 to Figure 4 Description of this embodiment, a centrifugal double-channel trace liquid quantitative sampling device is composed of a PDMS substrate 1 and a glass sheet 2, and the PDMS substrate 1 is placed on the surface of the glass sheet 2; the PDMS substrate The surface of 1 is provided with a first trace liquid quantitative sampling unit and a second trace liquid quantitative sampling unit;

[0029] The first trace liquid quantitative sampling unit includes a first waste liquid chamber 3, a first waste liquid chamber exhaust channel 4, a first liquid sampling hole 6, a first inverted V-shaped liquid quantitative chamber 7, a first liquid injection Cut off the air inlet channel 8 and the liquid outlet channel 10; the exhaust channel 4 of the first waste liquid chamber is arranged on the first waste liquid chamber 3; one end of the first inverted V-shaped liquid quantitative chamber 7 is connected to the first liqui...

specific Embodiment approach 2

[0037] Embodiment 2. This embodiment is a manufacturing method of a centrifugal dual-channel trace liquid quantitative sampling device described in Embodiment 1. The method is completed by the following steps:

[0038] Step 1. On SiO 2 The surface of the single wafer is spin-coated with photoresist, and the first waste liquid chamber 3, the first waste liquid chamber exhaust channel 4, and the first inverted V-shaped liquid quantitative sampling unit are photoetched out. Chamber 7, the first liquid interrupts the intake passage 8, the liquid outlet passage 10, the second waste liquid chamber 13 in the second trace liquid quantitative sampling unit, the second waste liquid chamber exhaust passage 14, the second inverted V-shaped The liquid quantitative cavity 17, the second liquid interrupt the SiO of the intake channel 18 and the gas blocking valve exhaust channel 20 2 mask pattern;

[0039] Step 2, the SiO obtained in step 1 2 Evaporate a 1 μm thick aluminum film on the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com