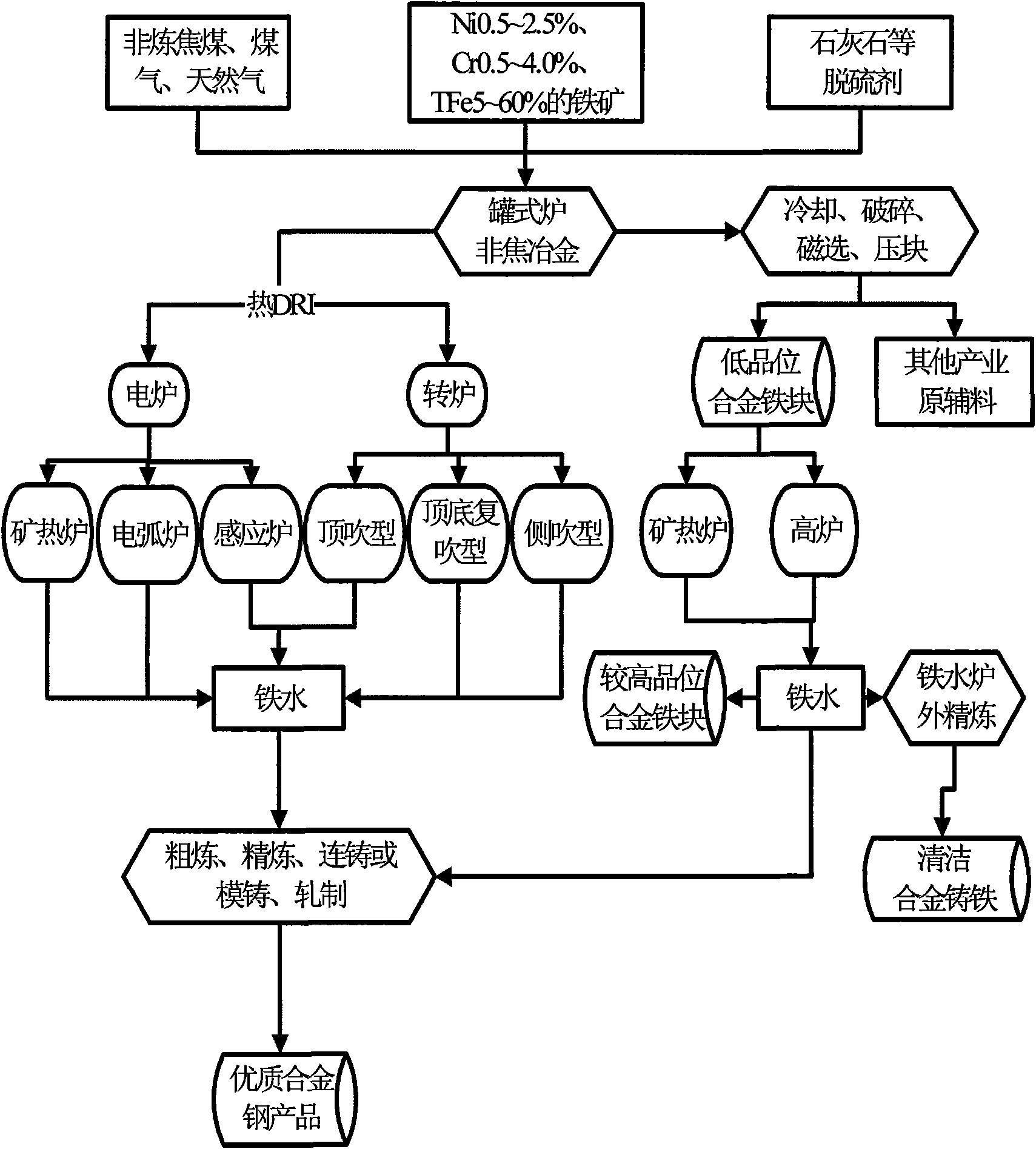

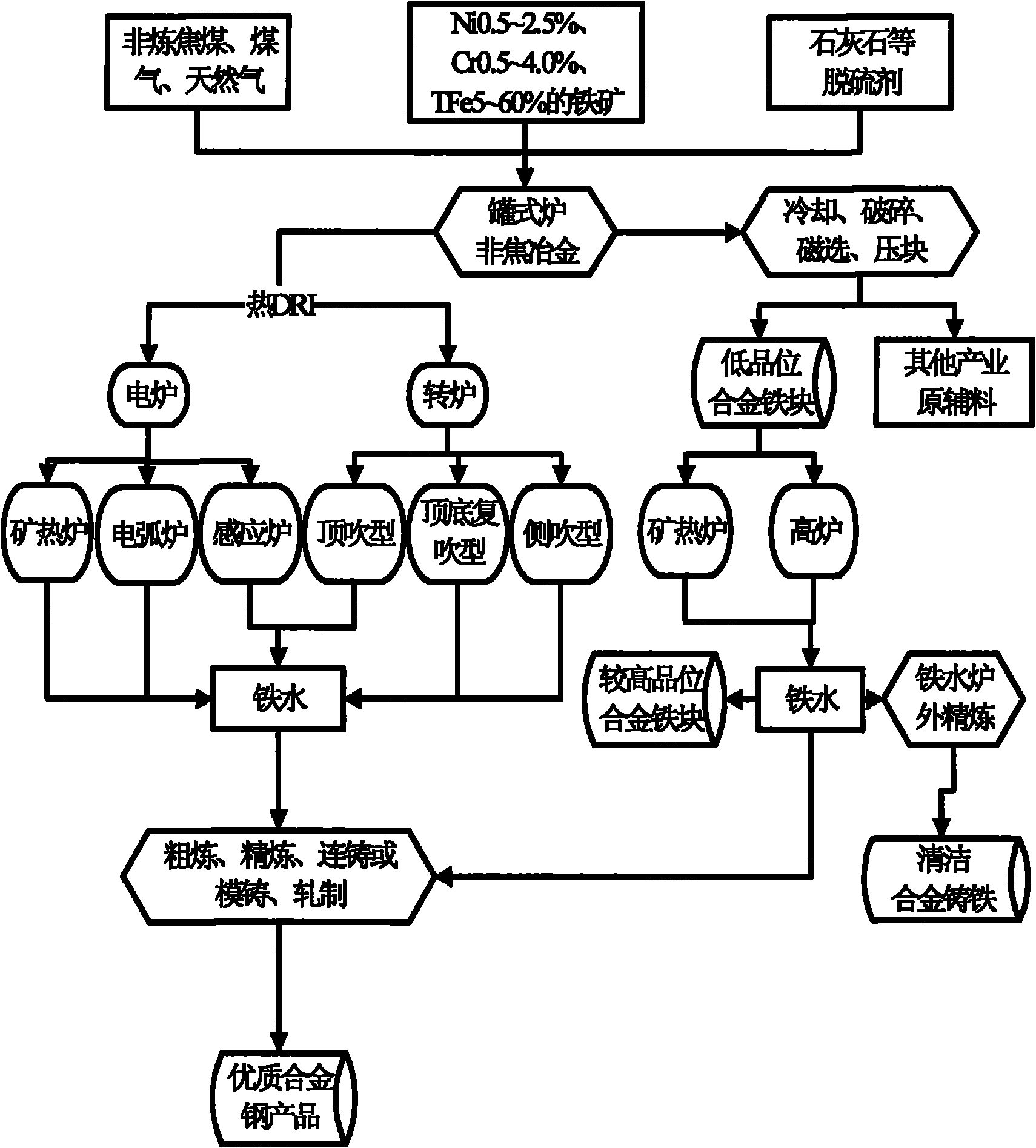

Method for producing alloy steel by directly utilizing low-grade nickel-chromium commensal iron ore

A technology for producing alloy steel and nickel-chromium alloy, applied in the field of alloy steel smelting, can solve the problems of huge treatment costs, less coking coal resources, and high energy consumption, so as to reduce project investment and production costs, improve economic and social benefits, and energy consumption. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the method of the present invention to directly utilize low-grade nickel-chromium intergrowth iron ore to produce alloy steel, the following examples will be described in more detail.

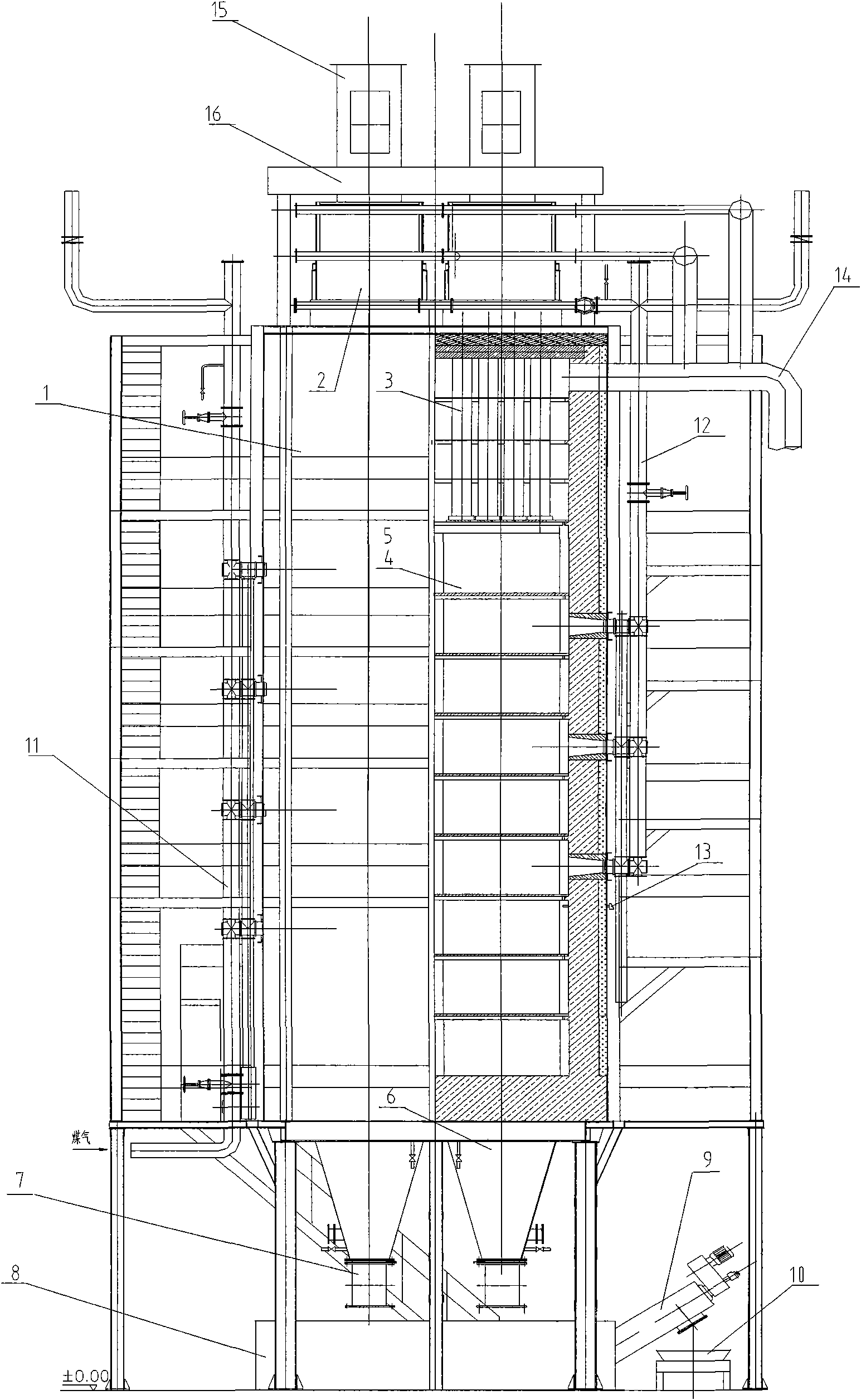

[0029] figure 2 It is a schematic diagram of the tank furnace in the method of directly utilizing low-grade nickel-chromium symbiotic iron ore to produce alloy steel in the present invention, which is the key equipment of the method of the present invention to directly utilize low-grade nickel-chromium symbiotic iron ore to produce alloy steel.

[0030] The tank furnace includes more than one group of reaction vertical tanks, and each group of reaction vertical tanks includes a preheating section 3 and a reduction section 4 connected up and down. For vertical tanks constructed of refractory materials, the reducing section of the reaction tank is a rectangular vertical tank with a width of 300-500mm, an aspect ratio greater than 3, and a height of 6-12 mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com