Modified fish skin collagen and preparation method

A fish skin collagen and modification technology, applied in the field of food packaging and processing, can solve the problems of poor mechanical properties and rheological properties of fish skin collagen, and achieve the effects of overcoming poor mechanical properties, simple process and improving gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

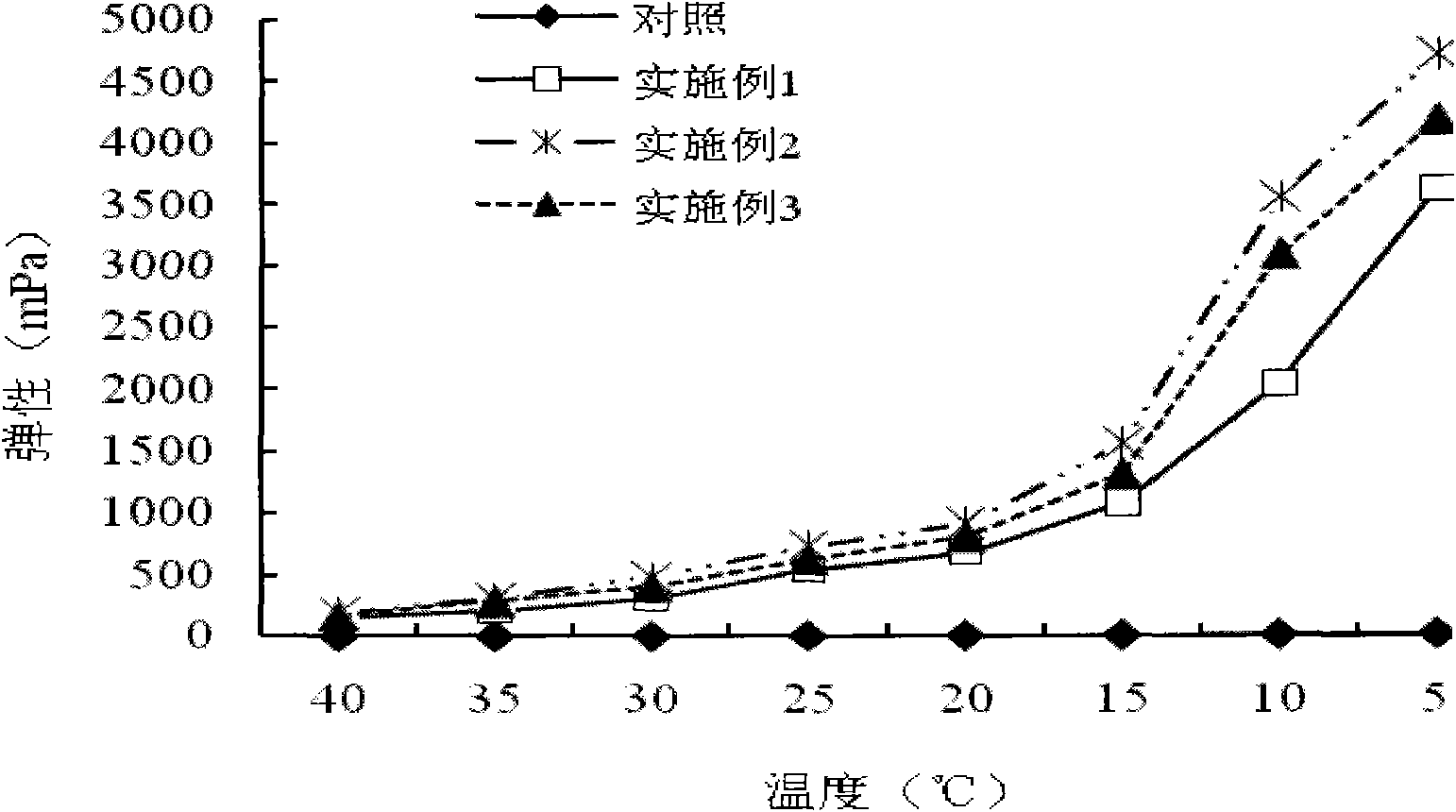

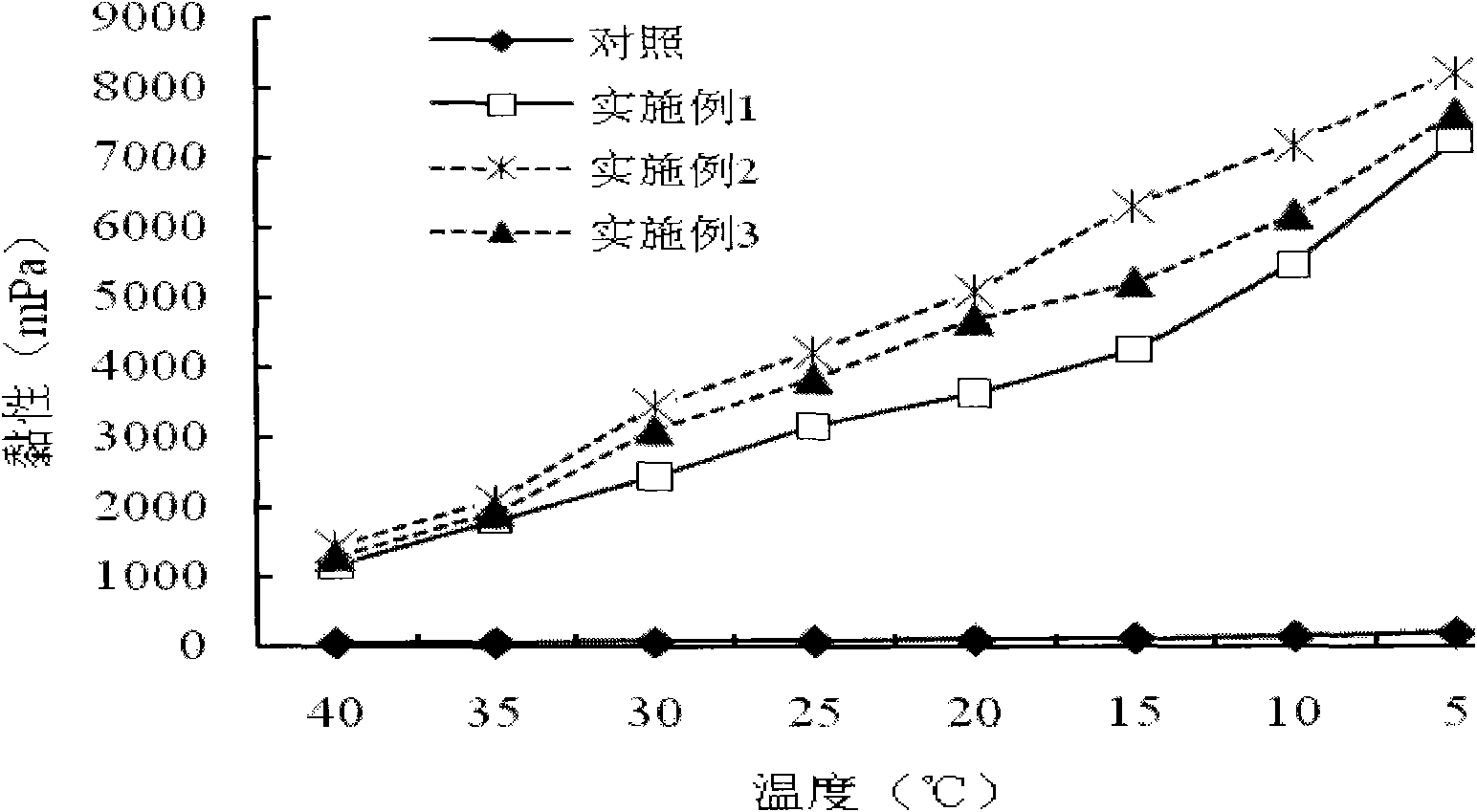

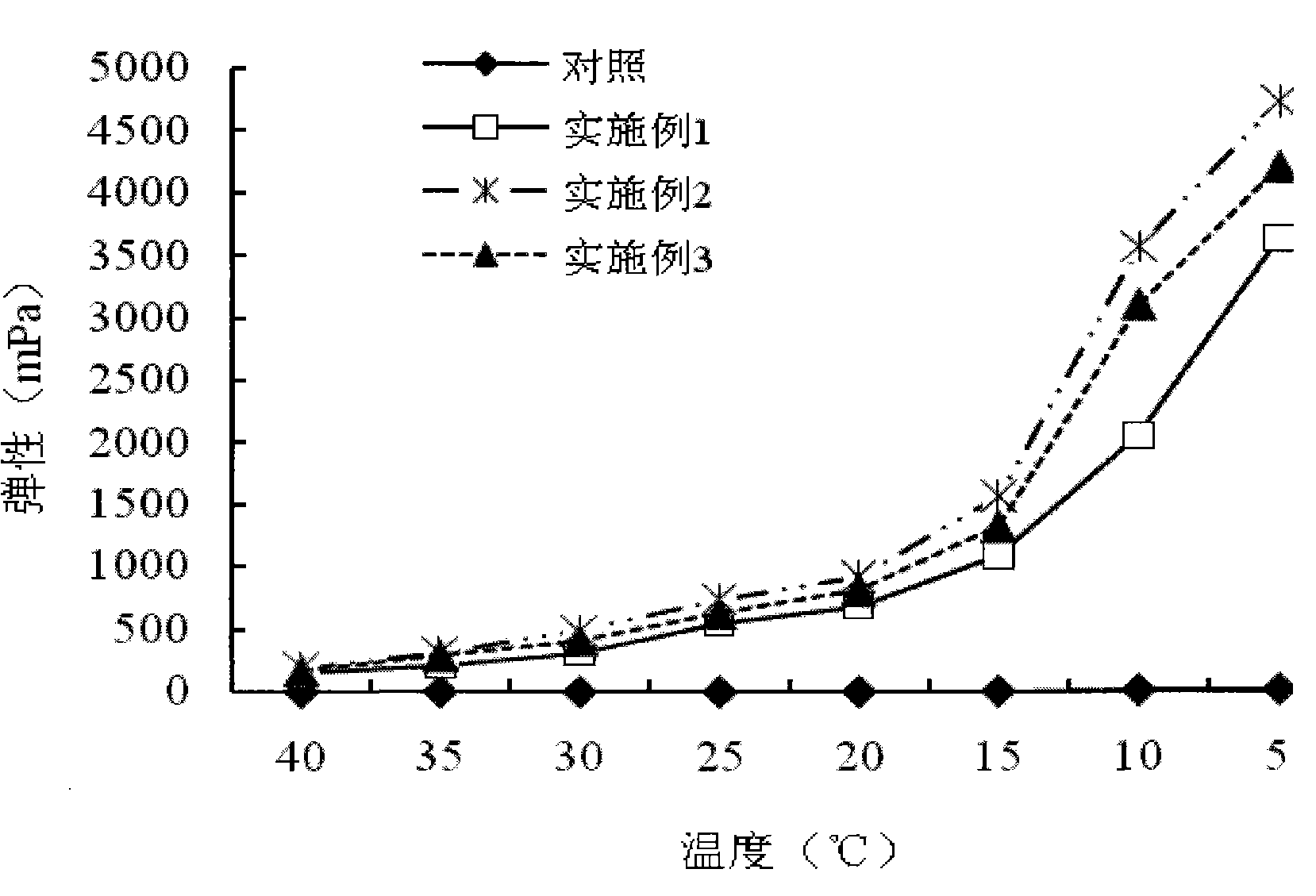

[0013] Prepare fish skin collagen (collagen content above 95%, molecular weight about 3 million Daltons) into a 6.67% (g / ml) aqueous solution, place it at room temperature until the collagen fully swells, and then place it in a water bath at 40°C for 30 minutes When the collagen is fully dissolved, then add transglutaminase (in an amount of 2% of the weight of the collagen in the solution) to the collagen solution, place it in a water bath at 40°C and heat until the transglutaminase is fully dissolved, then take the solution Mix with 2% chitosan acetic acid solution (85% degree of deacetylation, molecular weight 200,000 Daltons) in a ratio of 1:1, homogenize for 5 minutes, vacuum degassing for 5 minutes, and then place in a water bath at 40°C for 30 minutes to heat the two Fully cross-linked to obtain the modified fish skin collagen solution. The prepared modified collagen solution was characterized by texture analyzer and rheometer. The gel strength was 80g, the elastic modul...

Embodiment 2

[0015] Fish skin collagen (collagen content above 95%, molecular weight about 3 million Daltons) is prepared into a 6.67% aqueous solution, placed at room temperature until the collagen is fully swollen, and then heated in a 45°C water bath until the collagen is fully dissolved. Then add glutamine transaminase (addition amount is 2.5% of collagen protein weight in the solution) to this collagen protein solution, place 45 ℃ of water baths and heat until glutamine transaminase fully dissolves, take this solution and 2% chitosan Sugar acetic acid solution (91% degree of deacetylation, molecular weight 500,000 Daltons) was mixed at a ratio of 1:1, homogenized for 5 minutes, vacuum degassed for 5 minutes, and then heated in a water bath at 45°C for 30 minutes until the two were fully cross-linked to obtain Modified fish skin collagen solution. The modified collagen solution was characterized by texture analyzer and rheometer. The gel strength was 90g, the elastic modulus (25°C) was...

Embodiment 3

[0017] Fish skin collagen (collagen content above 95%, molecular weight about 3 million Daltons) is formulated into a 6.67% aqueous solution, placed at room temperature until the collagen is fully swollen, and then heated in a 50°C water bath until the collagen is fully dissolved. Then add glutamine transaminase (addition amount is 3% of collagen protein weight in the solution) in this collagen protein solution, place 50 ℃ of water baths and heat until glutamine transaminase fully dissolves, get this solution and 2% chitosan Sugar acetic acid solution (91% degree of deacetylation, molecular weight 500,000 Daltons) was mixed at a ratio of 2:1, homogenized for 5 minutes, vacuum degassed for 5 minutes, and then heated in a water bath at 50°C for 20 minutes until the two were fully cross-linked to obtain Modified fish skin collagen solution. The modified collagen solution was characterized by texture analyzer and rheometer. The gel strength was 87g, the elastic modulus (25°C) was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com