Polyester and production method thereof

A technology of polyester and transesterification reaction, which is applied in the field of hydrolysis-resistant polyester and its production, can solve the problems of impact and unfavorable performance of polyester products, and achieve the effect of improving hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

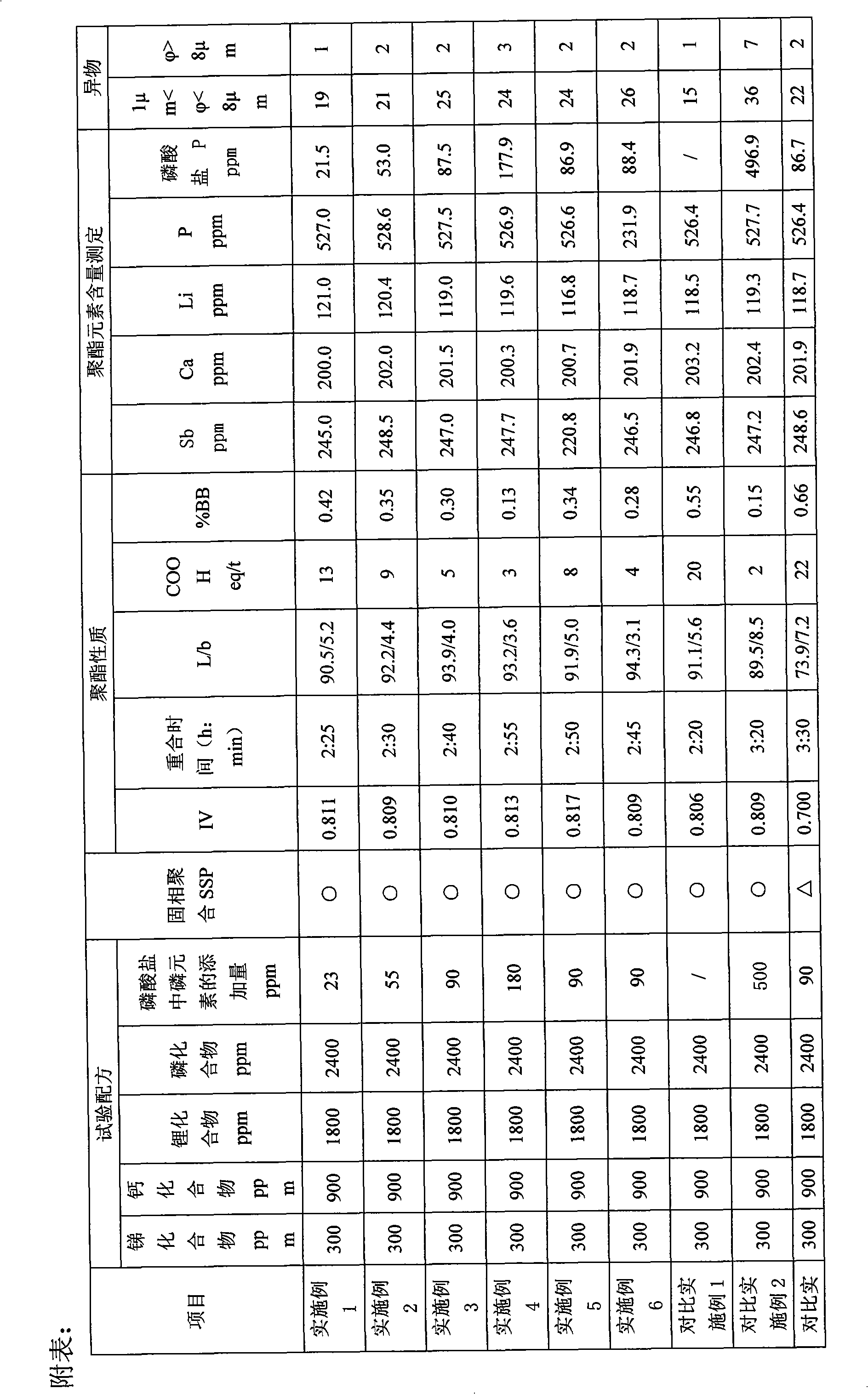

Examples

Embodiment 1

[0042] A hydrolysis-resistant polyester is a polyester synthesized by the transesterification method. Add inorganic antimony compounds and organic acid calcium compounds as catalysts in the transesterification process, add organic acid lithium compounds at the end of the transesterification reaction, and organic phosphorus compounds as catalysts in the polycondensation reaction;

[0043] Perform polycondensation reaction and solid-phase polymerization of the obtained small molecule polymer;

[0044] Inorganic phosphate as a buffer can be added before the transesterification reaction or after the transesterification or during the polycondensation reaction. The content of phosphorus in the phosphate is 1-200 ppm relative to the weight of the polyester.

[0045] The temperature of solid-phase polymerization is 180-240°C, and the preferred range is 210-230°C, and the vacuum degree of solid-phase polymerization is ≤130pa.

[0046] Among them, the polyester is polyethylene terephthalate obt...

Embodiment 2

[0061] Relative to the weight of polyester, the dosage of the following substances is:

[0062] Antimony compound 300ppm;

[0063] Calcium compound 900ppm;

[0064] Lithium compound 1800ppm;

[0065] Phosphorus compound 2400ppm;

[0066] The content of phosphorus in sodium dihydrogen phosphate is 55 ppm;

[0067] The rest is the same as in Example 1. The superposition time of the low-viscosity polyester was 2 hours and 30 minutes, the viscosity (IV) of the finally obtained polyester was 0.809, the hue L value of the polyester chips was 92.2, and the b value was 4.4. The COOH content of the polyester before the hydrolysis treatment was 9eq / t, and the BB% was determined to be 0.35 after the hydrolysis treatment. The results of the observation of foreign bodies were: 21 foreign bodies with a diameter of 1 to 8 μm, and 2 foreign bodies with a diameter larger than 8 μm.

Embodiment 3

[0069] Relative to the weight of polyester, the dosage of the following substances is:

[0070] Antimony compound 300ppm;

[0071] Calcium compound 900ppm;

[0072] Lithium compound 1800ppm;

[0073] Phosphorus compound 2400ppm;

[0074] The content of phosphorus in sodium dihydrogen phosphate is 90ppm;

[0075] The rest is the same as in Example 1. The superposition time of the low-viscosity polyester is 2 hours and 40 minutes, the viscosity (IV) of the finally obtained polyester is 0.810, the hue L value of the polyester chips is 93.9, and the b value is 4.0. The COOH content before the hydrolysis treatment of the polyester is 5eq / t, and the BB% is determined to be 0.30 after the hydrolysis treatment. The results of the observation of foreign bodies are: the number of foreign bodies between 1 and 8 μm is 25, and the number of foreign bodies larger than 8 μm is 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com