Method for removing trace polycyclic aromatic hydrocarbon from water through quick adsorption

A technology for polycyclic aromatic hydrocarbons and water removal, applied in the direction of adsorption of water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of poor performance of organic matter, achieve strong adsorption capacity, fast adsorption, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Wherein the preparation steps of the electrospun nanofiber membrane include:

[0034]1) Polylactic acid-caprolactone co-(P(LA / CL), 7 / 3) particles with a molecular weight of 100,000 were dissolved in methylene chloride, and a block copolymer surfactant was added to optimize spinning performance, Stir for 2 hours after uniform mixing to obtain a mixed gel, wherein the amount of block copolymer F108 is 17% of the weight of polylactic acid-caprolactone (P(LA / CL), 7 / 3);

[0035] 2) The high-voltage electrospinning equipment consists of a DC high-voltage power supply, a spinneret and a receiving device. The mixed gel obtained in step 1) was introduced into a high-voltage electrospinning device, the power supply voltage was adjusted to 10 kV, and the receiving distance was 15 cm to obtain stable and continuous spraying. During the whole process of spinning, infrared light is used to irradiate the dichloromethane completely;

[0036] 3) Collect the electrospun fiber membrane ...

Embodiment 1

[0047] 1.2 grams of polylactic acid-caprolactone (P(LA / CL), 7 / 3) was dissolved in 20 grams of dichloromethane, and then 0.2 grams of block copolymer surfactant F018 was added, mixed evenly and stirred for 2 hours to obtain a mixed gel. The mixed gel is then introduced into a high-voltage electrospinning device to be spun. Adjust the voltage of the high-voltage power supply to 10 kV, and the receiving distance is 15 cm to obtain a stable and continuous jet stream, and collect the fiber product on the receiving plate covered with aluminum foil. During the whole process of spinning, infrared light was used to irradiate the dichloromethane completely. After 4 to 5 hours, when the thickness of the fiber membrane reaches 0.3 to 0.5 mm, the spinning is stopped to obtain polylactic acid-caprolactone (P(LA / CL), 7 / 3) electrospun nanofiber membrane. Electrospun nanofiber membranes of polylactic acid-caprolactone (P(LA / CL), 7 / 3) were characterized by fiber morphology under a field emiss...

Embodiment 2

[0050] The preparation steps of the electrospun nanofiber membrane are the same as in Example 1.

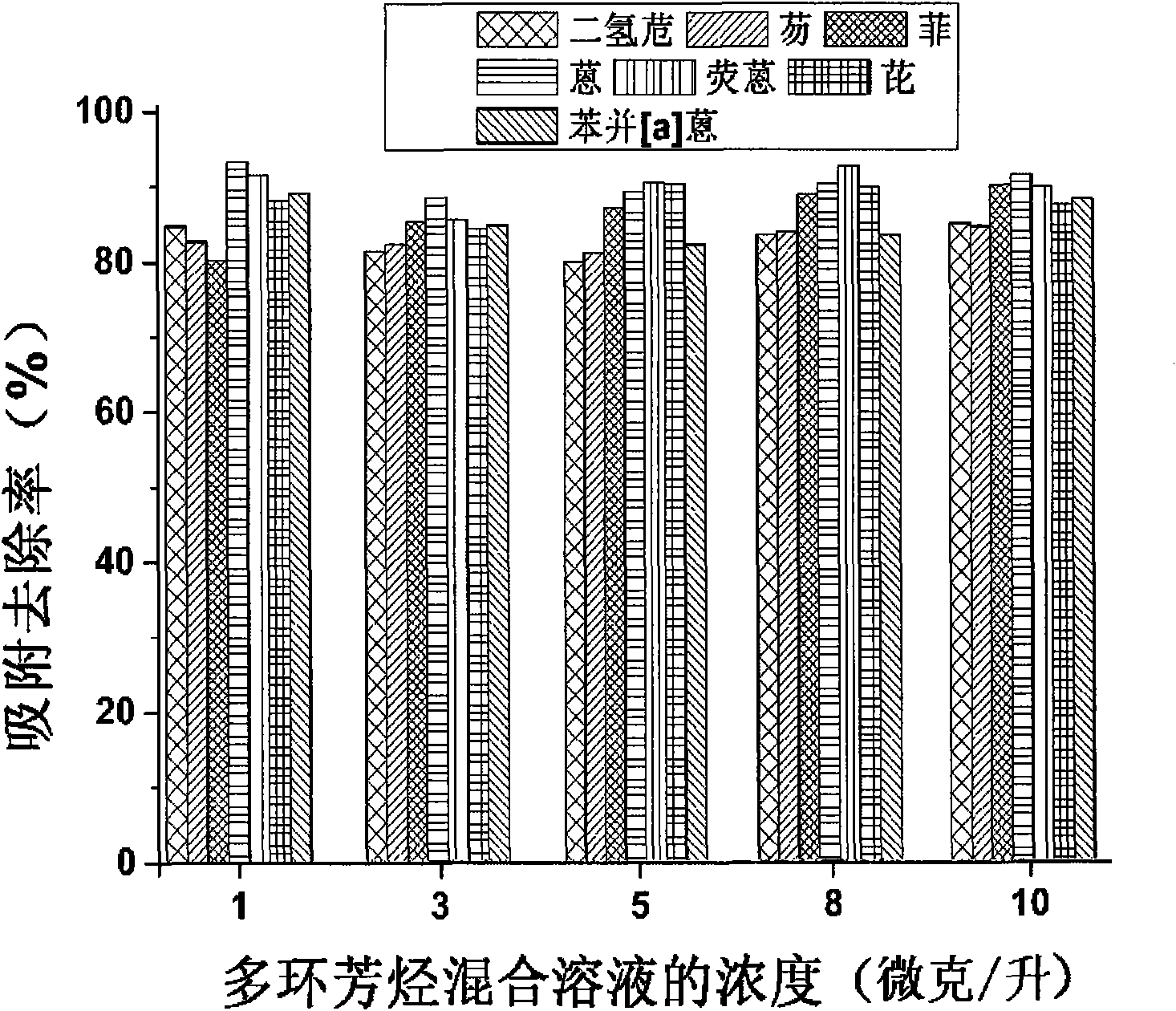

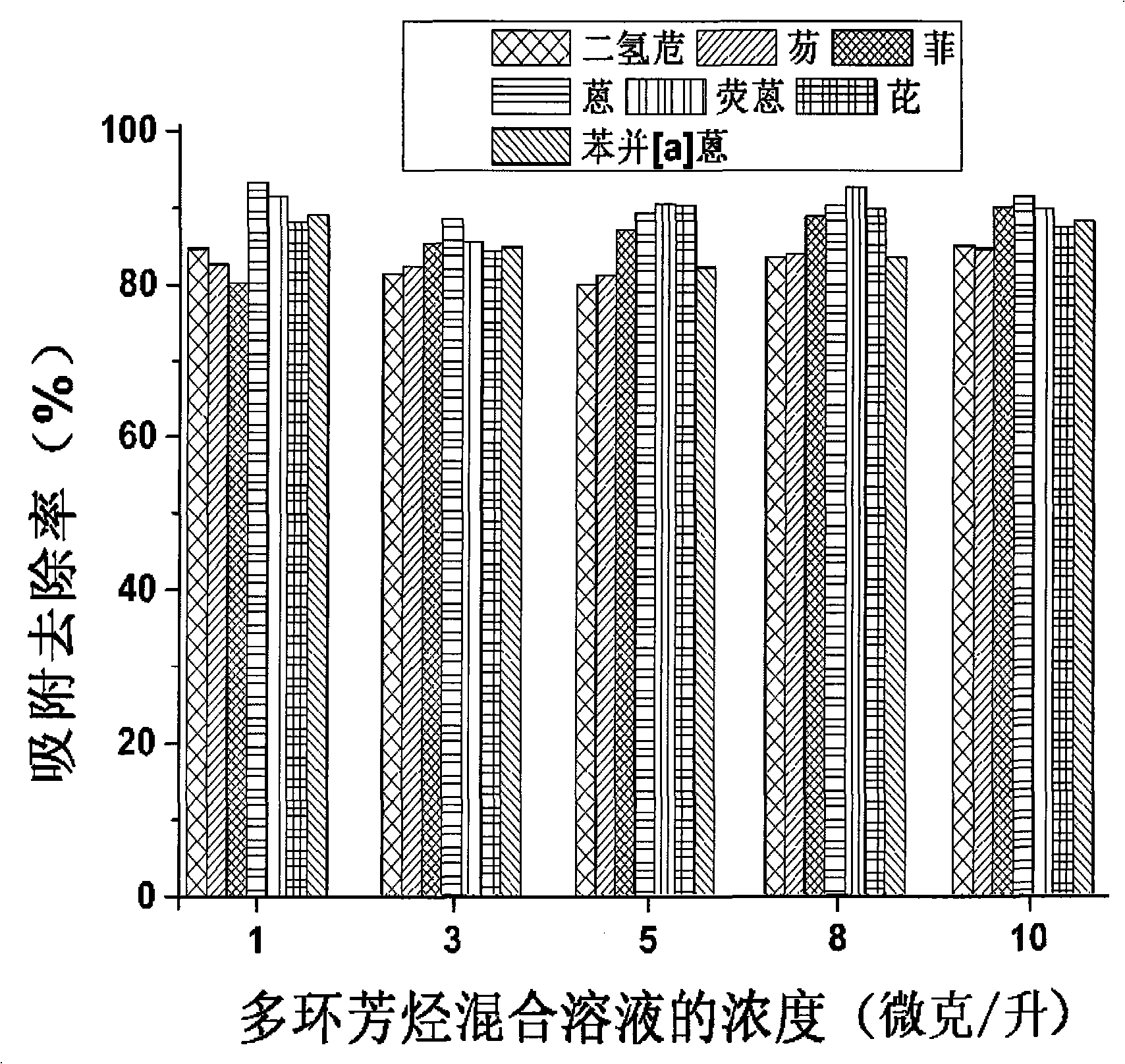

[0051] The resulting polylactic acid-caprolactone (P(LA / CL), 7 / 3) electrospun nanofibrous membrane was cut into 1.5 cm × 1.5 cm squares and peeled off from the aluminum foil. Then weigh 0.1 grams (about 5 pieces) of electrospun nanofiber membranes and add them to 50 milliliters of 7 kinds of polycyclic aromatic hydrocarbons mixed solutions with a concentration of 3 micrograms per liter; and place the mixed system at 30°C and 120 rpm Shake down, react after 20 minutes and take a sample and measure through high-performance liquid chromatography (DIONEX U3000, the U.S.), this method is respectively to the adsorption removal rate of 7 kinds of polycyclic aromatic hydrocarbons: dihydroacenaphthene 82.4%, fluorene 82.6%, phenanthrene 85.5%, Anthracene 88.6%, fluoranthene 85.6%, pyrene 84.4%, benzo[a]anthracene 84.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com