Roller grinder

A grinding machine and roller technology, which is used in grain processing, microwave heating, etc., can solve the problems of high temperature of heating device, large heat loss, and inability to realize grinding equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

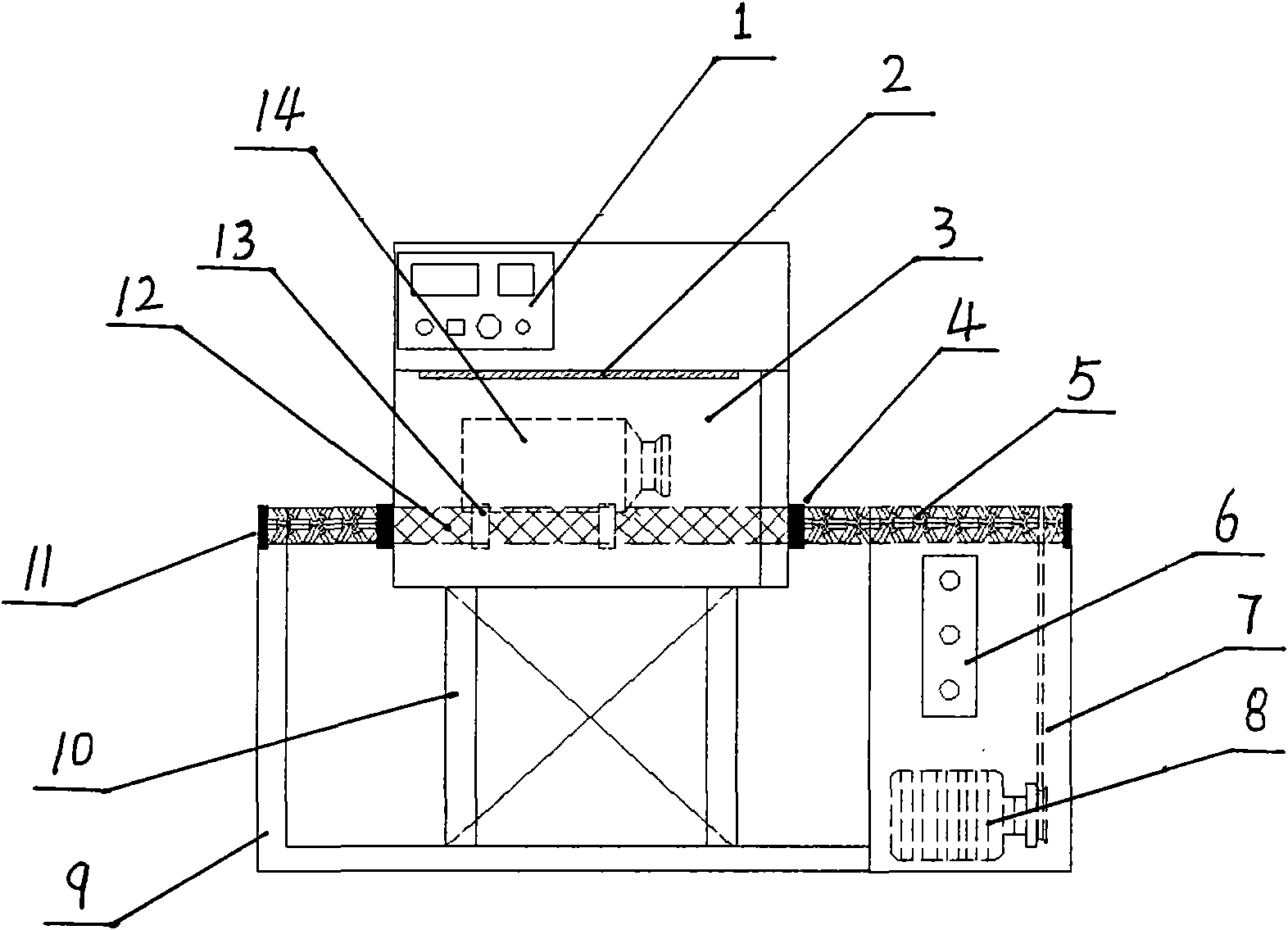

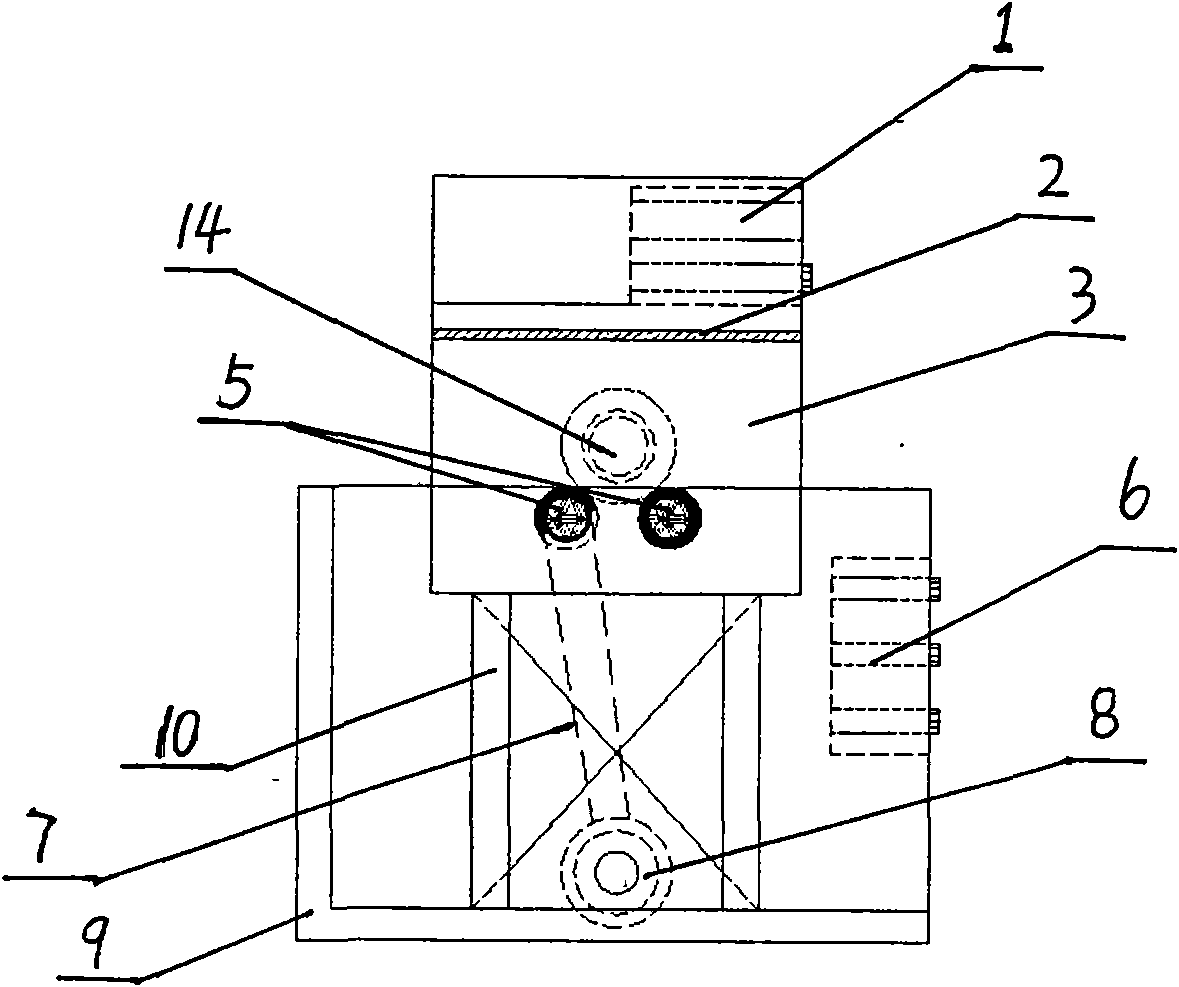

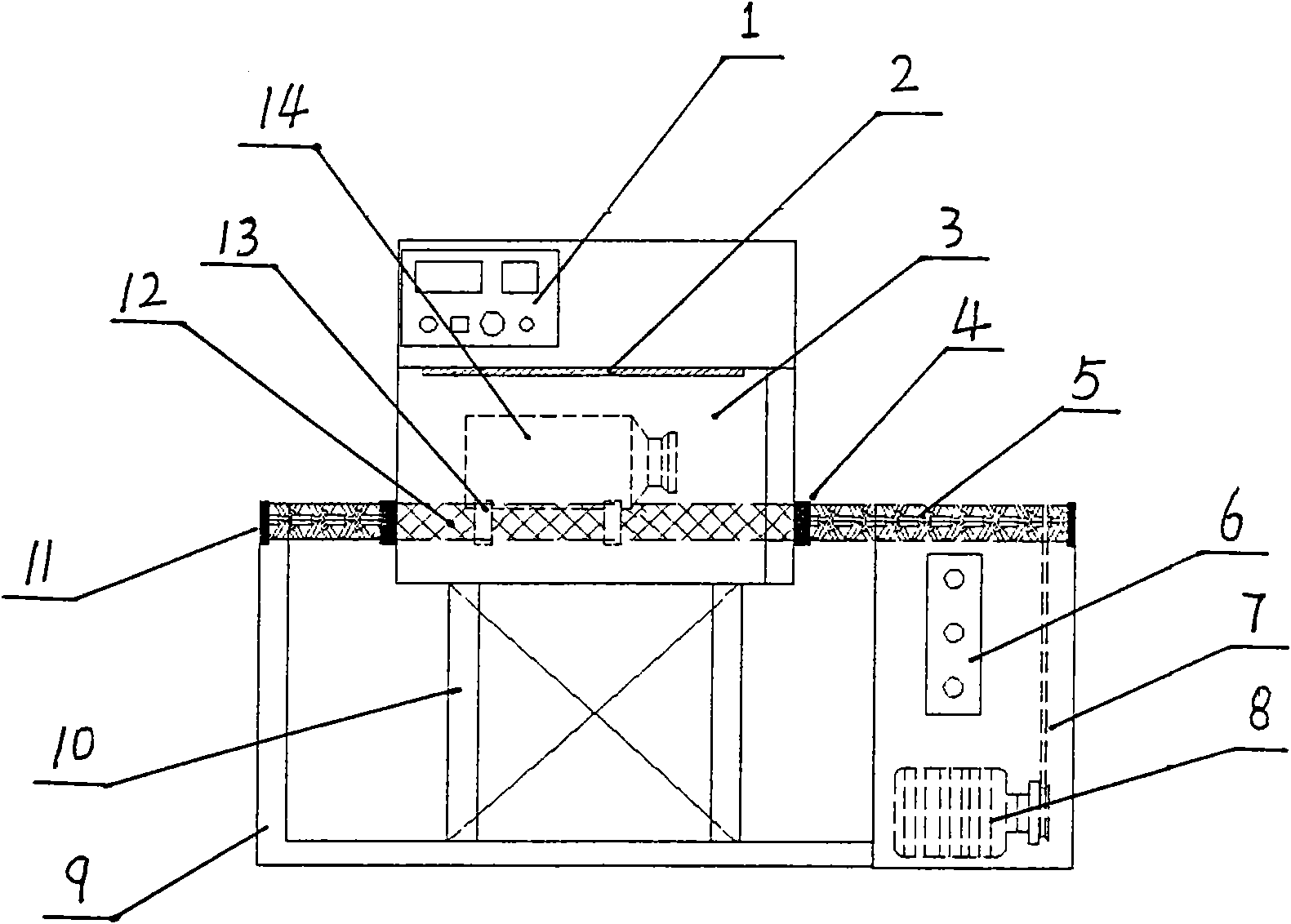

[0009] Depend on figure 1 , figure 2 It can be seen that the present invention includes: a parallel rolling shaft 5 , a grinding controller 6 , a belt 7 , a motor 8 , a chassis 9 , a metal fixture 11 , and a grinding tank 14 . The parallel rolling shaft 5 is fixed on the bottom frame by the metal fixing piece 11, the motor 8 drives the parallel rolling shaft 5 to rotate through the belt 7, the grinding controller 6 is connected with the motor 8 and is fixedly installed on its upper part, the speed and time of the grinding tank are controlled by the grinding device control. Grinding jar 14 interiors are equipped with grinding balls, and grinding balls adopt wear-resistant agate balls. The middle part of the parallel rolling shaft 5 is connected to a section of quartz parallel roller 12 through a metal sleeve 4, and a quartz grinding tank 14 is installed on the quartz parallel roller. The quartz grinding tank 14 and the quartz parallel roller 12 are made of high-purity quartz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com